Avers, K. E. (2011). Prioritizing maintenance human factors challenges and solutions: Workshop proceedings. (Report No. DOT/FAA/AM-11/11). Federal Aviation Administration, Office of Aerospace Medicine.

CAA. (2009, August). Legal notices and information bulletins. Retrieved from Civil Aviation Authority: https://www.aviation.govt.nz/assets/about-us/legal-information-bulletin-004.pdf

Drury, C. B. (2017). Why do we STILL not Follow Procedures? Proceedings of the Human Factors and Ergonomics Society 2017 Annual Meeting.

Drury, C. G. (2013). Writing aviation maintenance procedures that people can / will follow.

Proceedings of the Human Factors and Ergonomics Society Annual Meeting. Santa Barbara, CA: Sage Publications.

Drury, C. G. (2017). Failure to follow written procedures (Report No. DOT/FAA/AM-17/17).

Federal Aviation Administration, Office of Aerospace Medicine.

FAA. (1998, 09 07). AC 43.13-1B, Acceptable methods, techniques, and practices - Aircraft inspection and repair. Retrieved from Federal Aviation Administration - Advisory Circulars: Note: Advisory removed by FAA site admin

Fogarty, G. (2004). The role of organizational and individual differences variables in aircraft maintenance performance. International Journal of Applied Aviation Studies, 4 (3), 73-90.

Fogarty, G. J. (2003). Modelling errors and violations in high-risk industries. Proceedings of the 38th Australian Psychological Society Annual Conference (pp. 65-69). Melbourne, Australia: Australian Psychological Society.

Hobbs, A. &. (2000). Aircraft maintenance survey results. Canberra: Australian Transport Safety Bureau.

Hobbs, A. &. (2003). Associations between errors and contributing factors in aircraft maintenance. Human Factors: The Journal of the Human Factors and Ergonomics Society, 45, 186-201.

Hobbs, A. &. (2008). Patterns of error in confidential maintenance incident reports. The International Journal of Aviation Psychology, 10(1), 5-16.

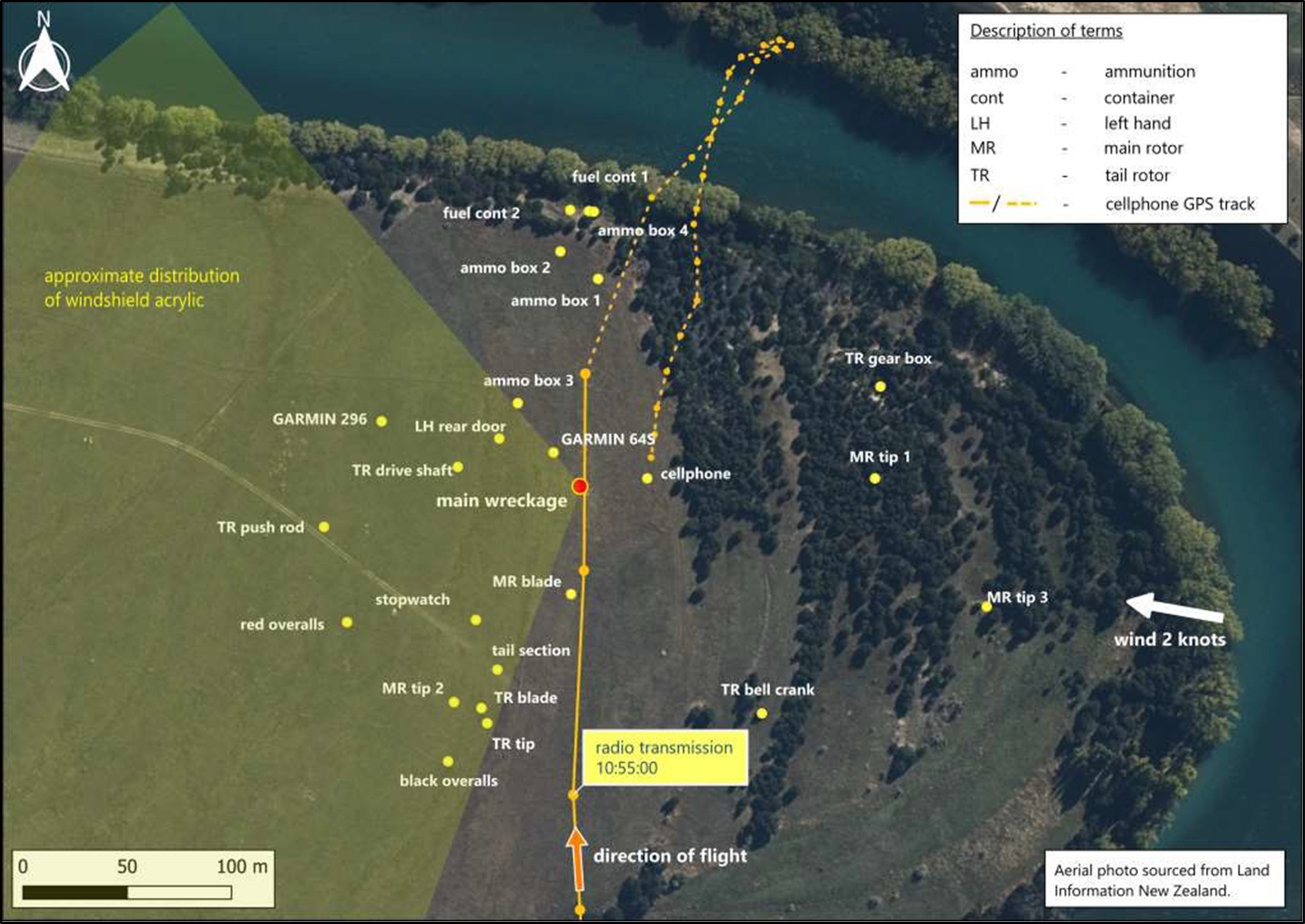

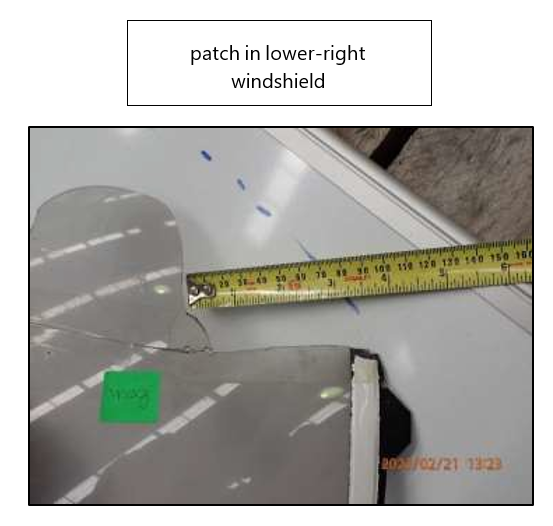

J.D Stachiw, J. S. (1989). Crazing and degradation of flexure strength in acrylic plates as a function of time. San Diego: Naval Oceans Systems Center, Technical report 1303.

Johnson, W. B. (2001). Installation Error in Airline Maintenance. Washington, DC: Federal Aviation Administration Office of Aviation Medicine.

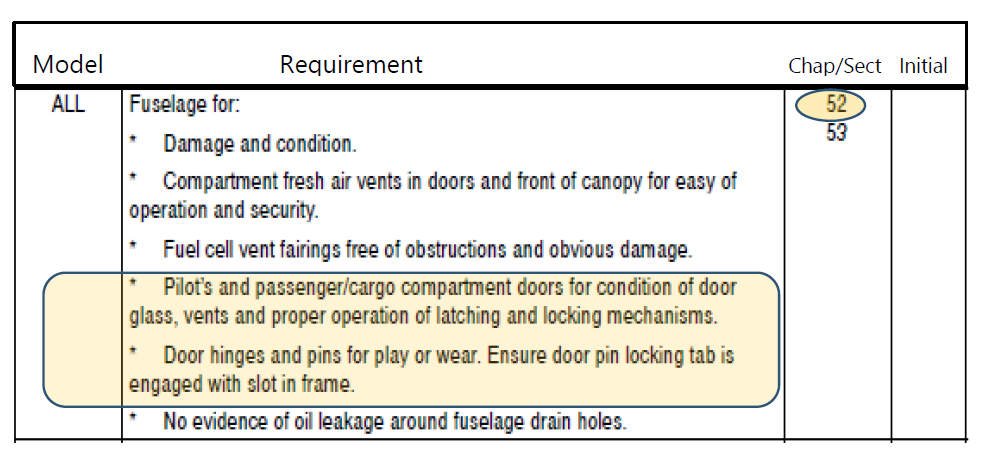

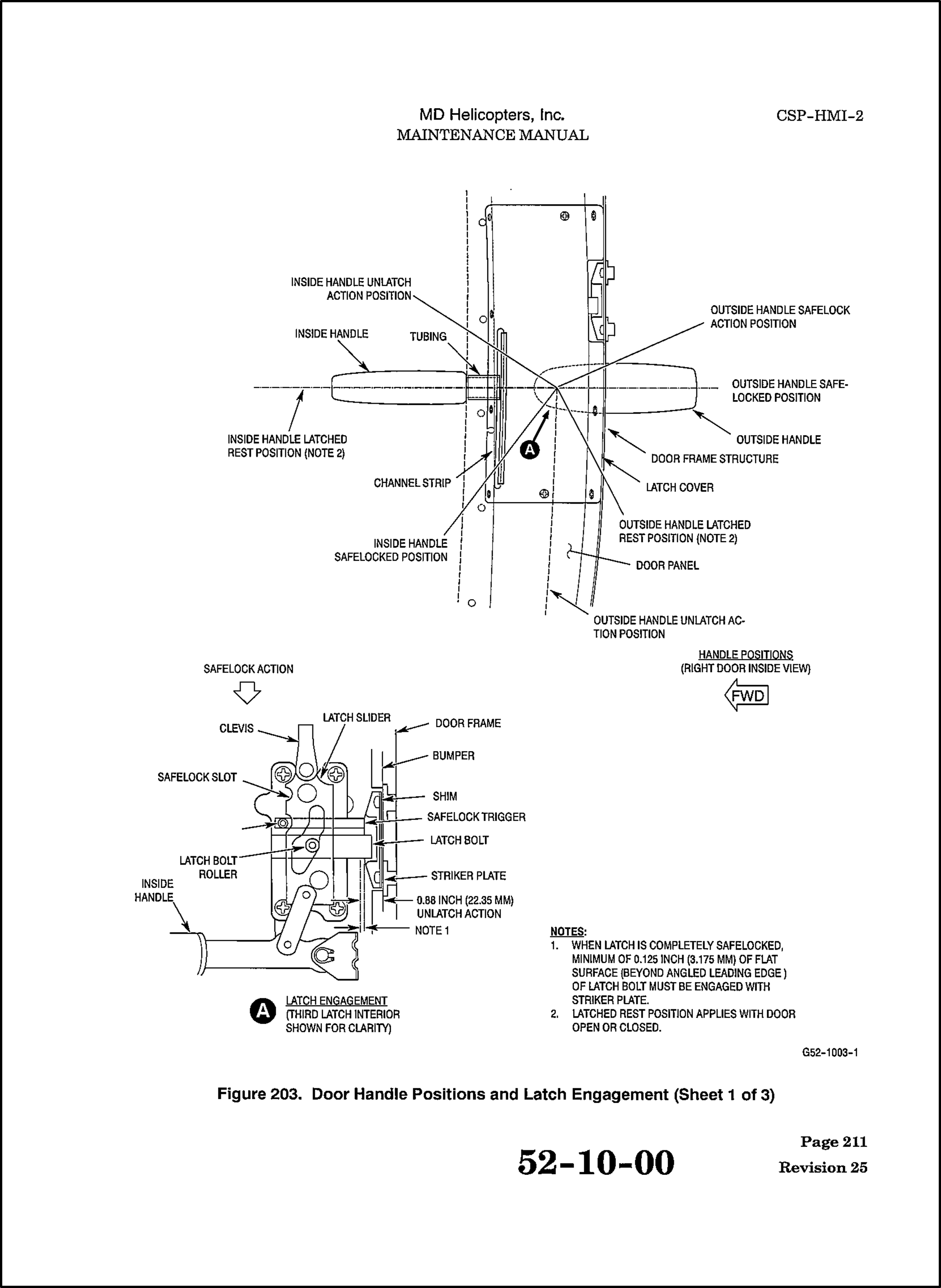

Key, K. S. (2022). Procedural compliance in aviation maintenance. Handbook of best practices and recommendations. . Federal Aviation Administration, Office of Aerospace Medicine.

NTSB. (1988). National Transportation Safety Board Aviation accident final report, Accident number NYC88LA083. Waterfall.

NTSB. (1989). National Transportation Safety Board Aviation accident final report, Accident number SEA90LA010. Neah Bay.

NTSB. (1993). Accident report LAX93LA323. Chico: National Transportation Safety Board, USA.

NTSB. (1995,1). Accident report LAX95FA225. Highland: National Transportation Safety Board,USA.

NTSB. (1995,2). Accident report LAX95TA328. Pearl City, Honolulu: National Transportation Safety Board, USA.

NTSB. (1997,1). Accident report LAX97FA107. Milolii, Hawaii: National Transportation Safety Board.

NTSB. (1997,2). Accident report FTW97LA347. Brinkley: National Transportation Safety Board.

NTSB. (1998). Accident report SEA98LA160. Oso: National Transportation Safety Board, USA. NTSB. (2000). Accident report LAX01FA006. Kernville: National Transportation Safety Board, USA.

NTSB. (2003). Accident report LAX03TA150. Pan Tak, Arizona: National Transportation Safety Board, USA.

NTSB. (2012). Accident report WPR13CA071. Pasadena: National Transportation Safety Board, USA.

NTSB. (2014). Accident report WPR14CA363. Willows: National Transportation Safety Board, USA.

Rankin, W. (2008). Safety management systems and Boeing-related safety activities.

Presented November 6-7 at the Safety Management System (SMS) Workshop for Air Transport Industry. Air Transport Industry.

Simula Inc. (1989). Aircraft crash survival design guide, Vol II - Aircraft design crash impact conditions and human tolerance. US Army Aviation Systems Command, AVSCOM. Phoenix: AVSCOM.

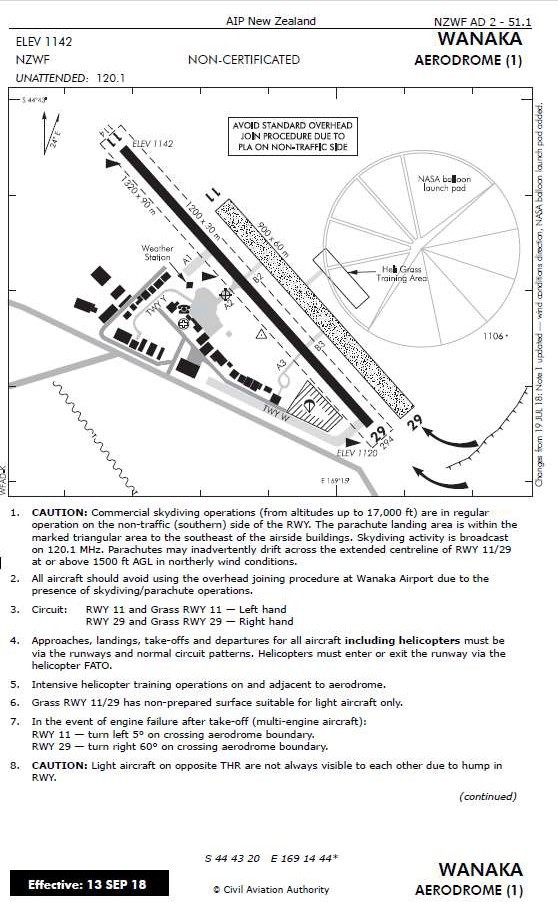

TAIC. (2010). Aviation inquiry AO-2010-009, Loss of control, Fox Glacier. Retrieved from Transport Accident Investigation Commission: www.taic.org.nz

TAIC. (2011). Aviation inquiry AO-2011-006, Runway excursion Pauanui Beach Aerodrome.

Retrieved from Transport Accident Investigation Commission: www.taic.org.nz

TAIC. (2014). Aviation Inquiry AO-2014-005, Collision with terrain, Mt Alta. Retrieved from Transport Accident Investigation Commission: www.taic.org.nz

TAIC. (2015). Aviation inquiry AO-2015-007, Collision with terrain, Fox Glacier. Retrieved from Transport Accident Investigation Commission: www.taic.org.nz

TAIC. (2017). Aviation Inquiry AO-2017-004, Loss of control, Porirua Harbour. Retrieved from Transport Accident Investigation Commission: www.taic.org.nz

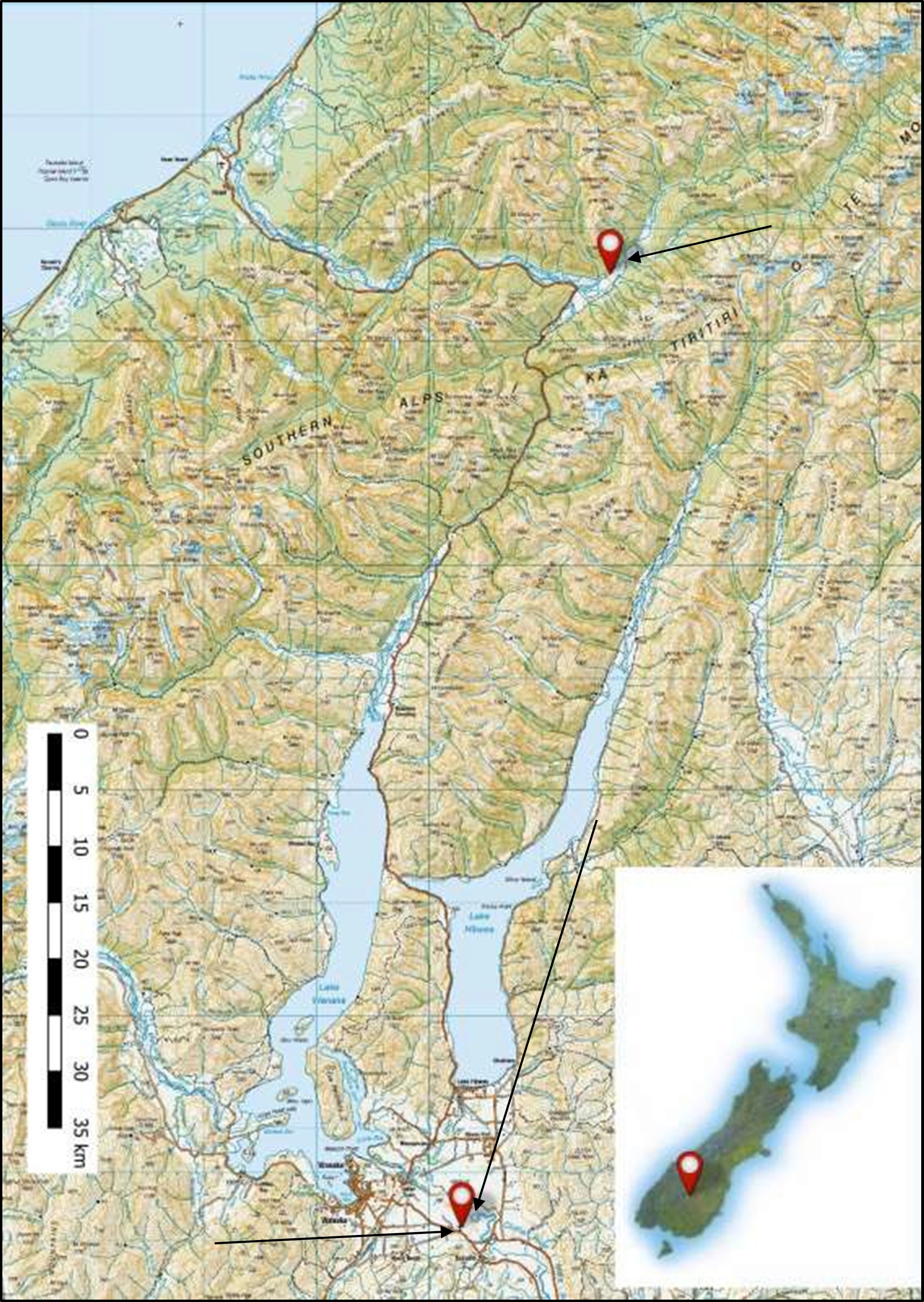

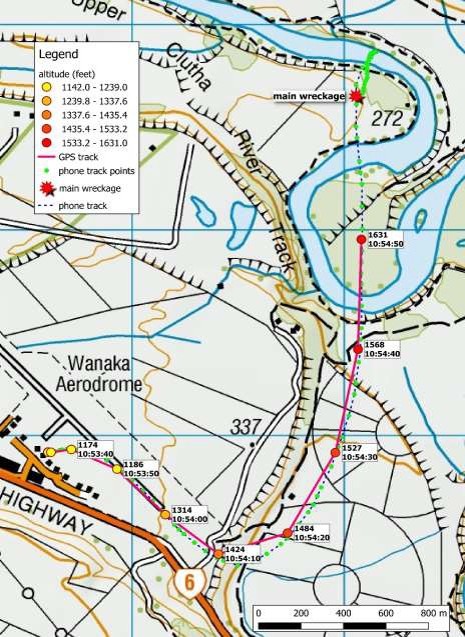

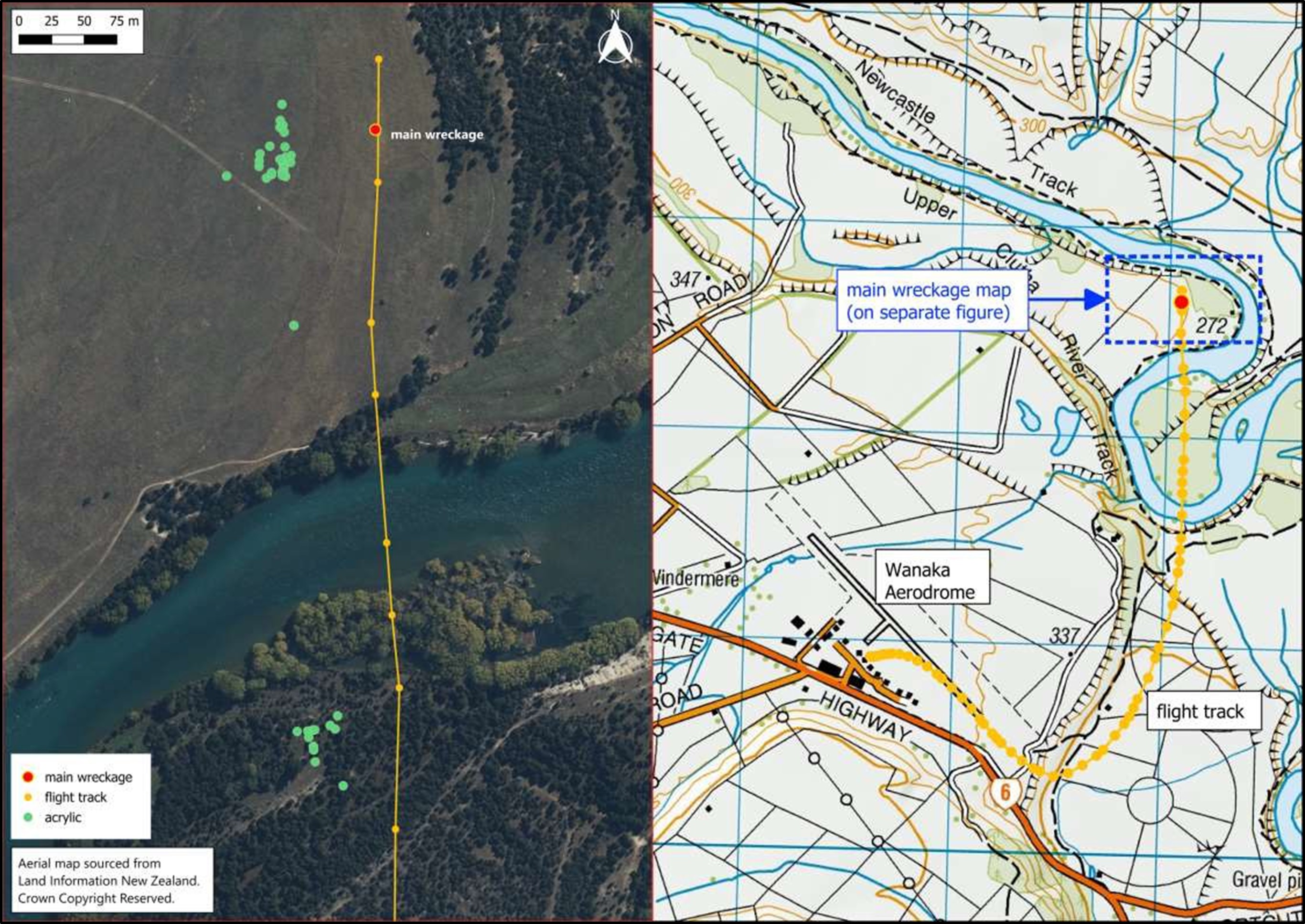

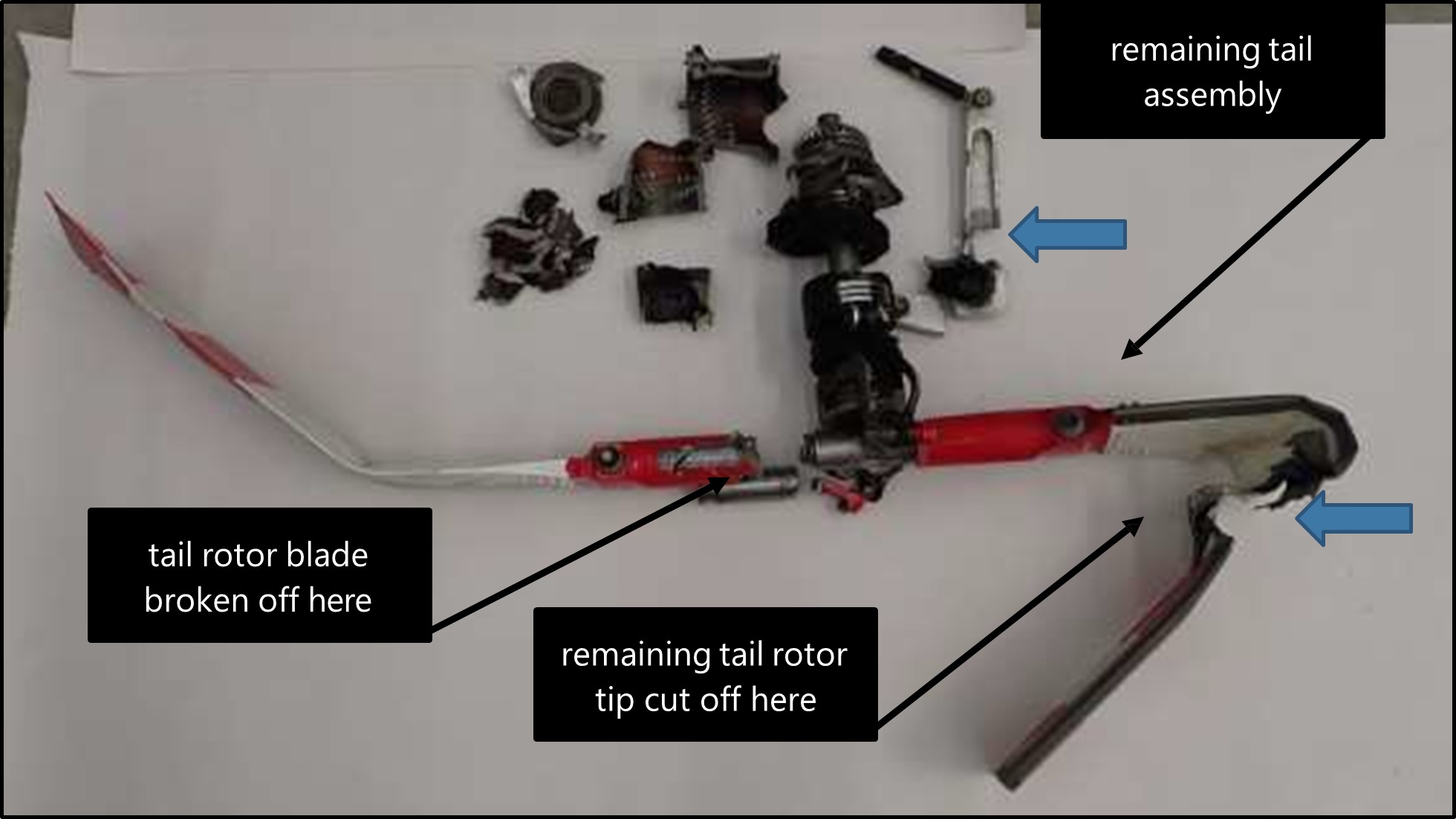

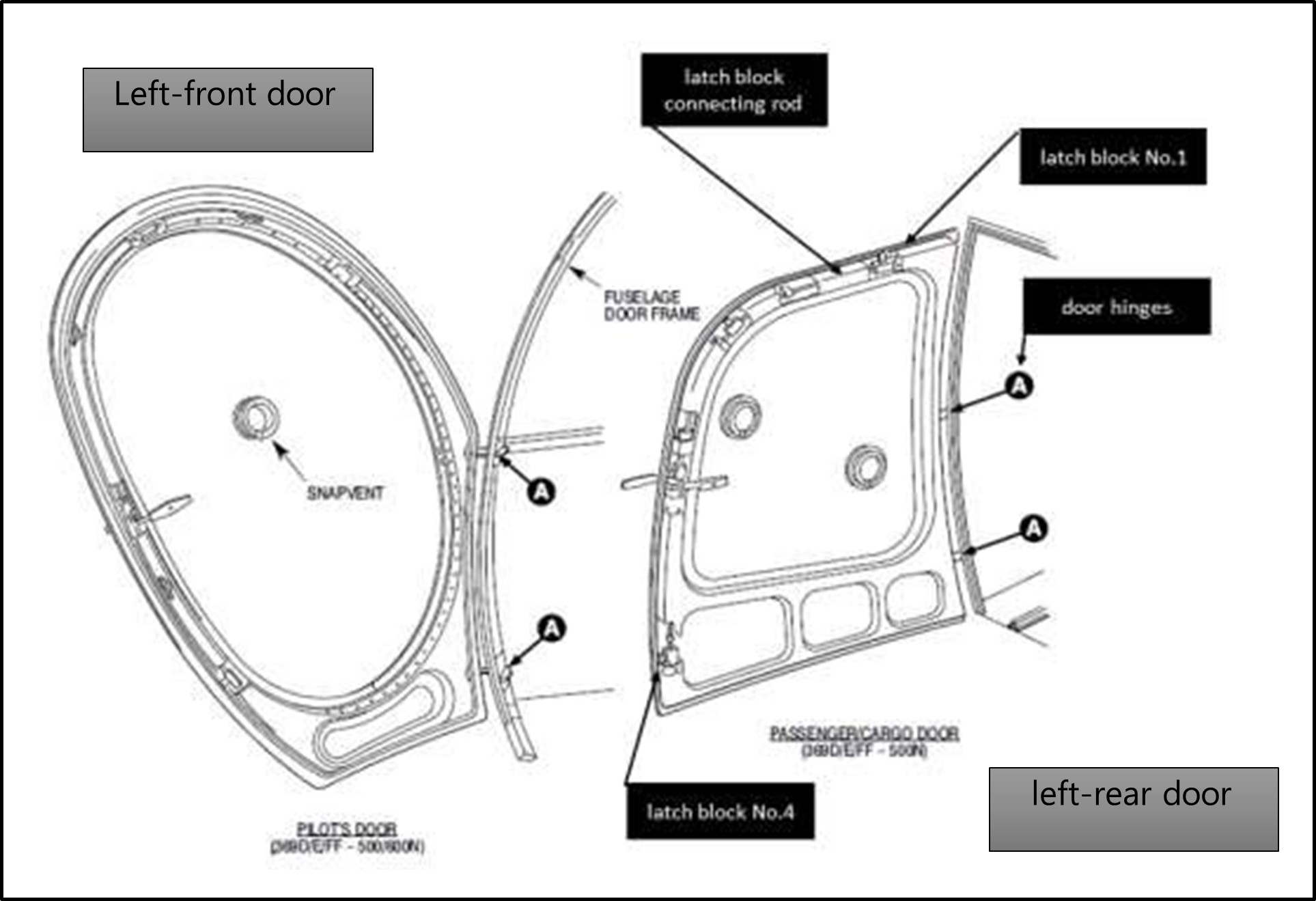

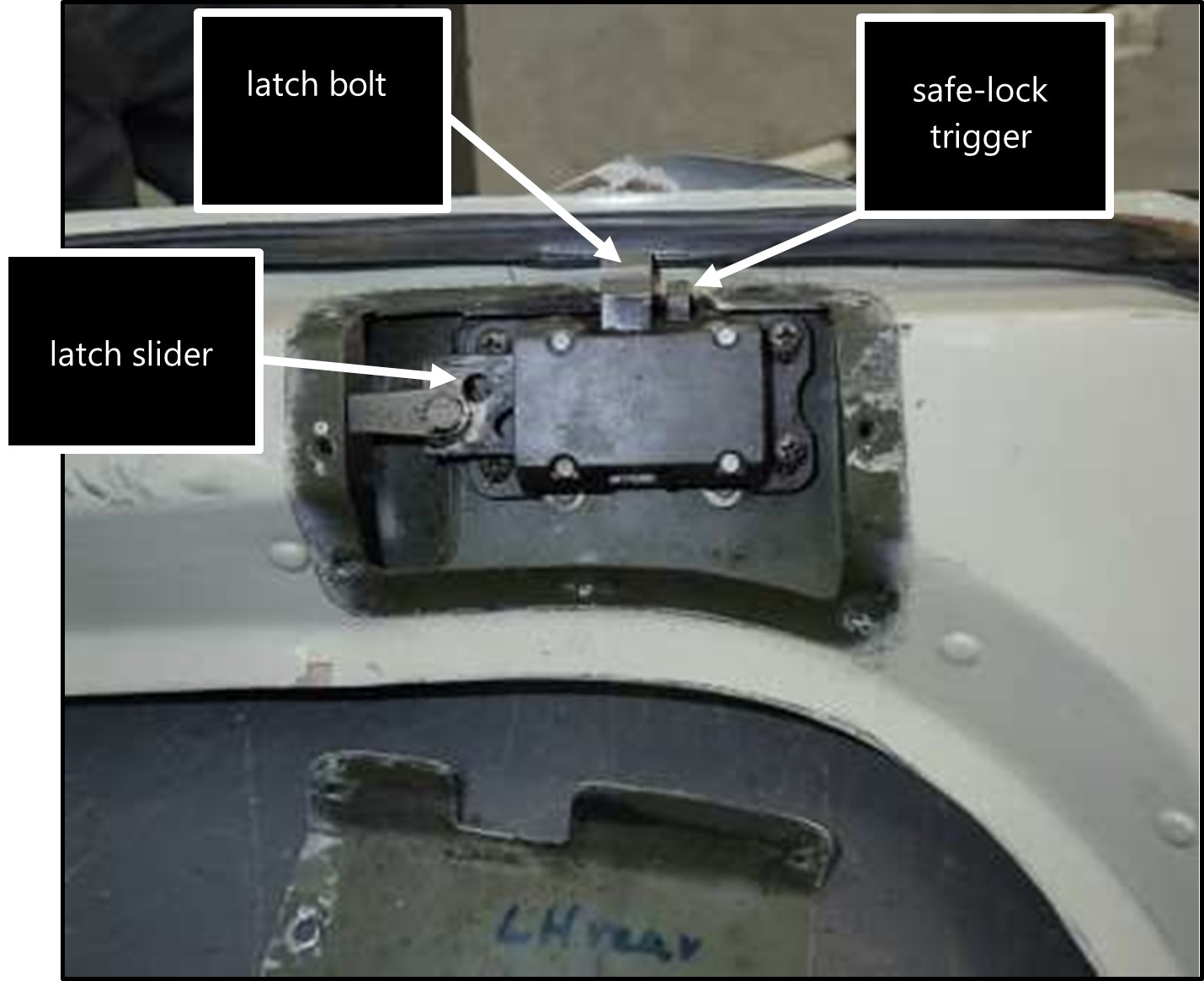

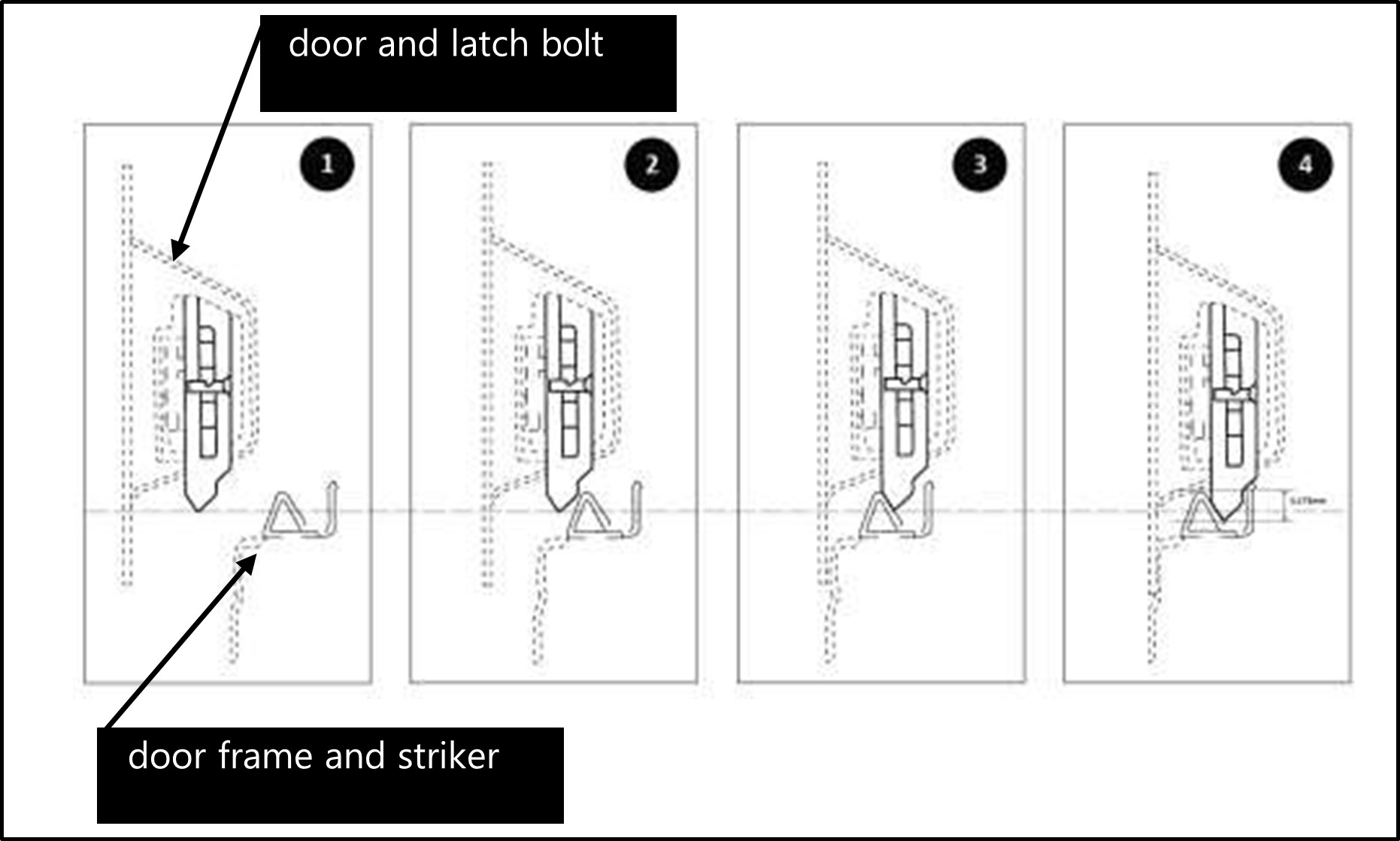

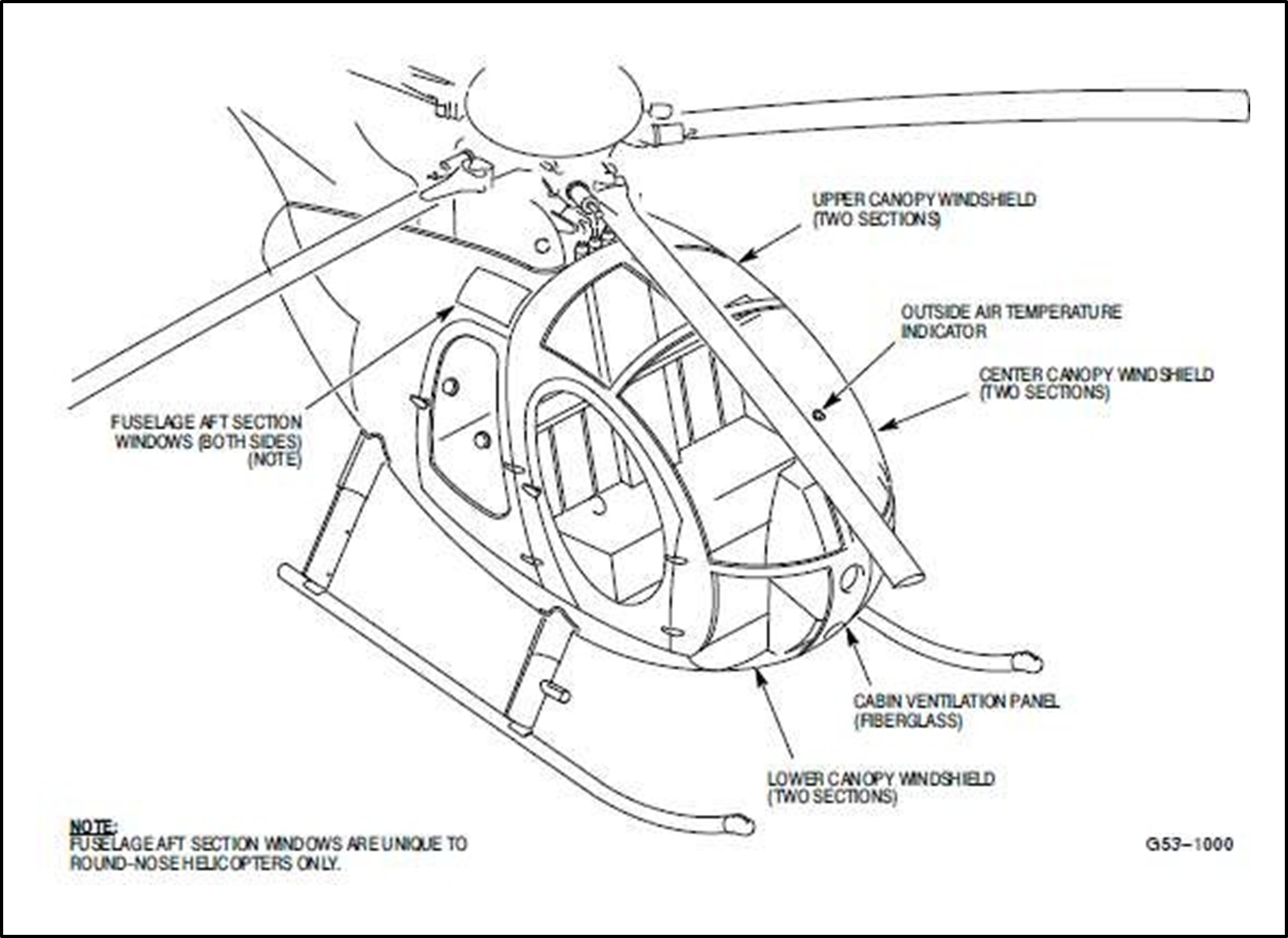

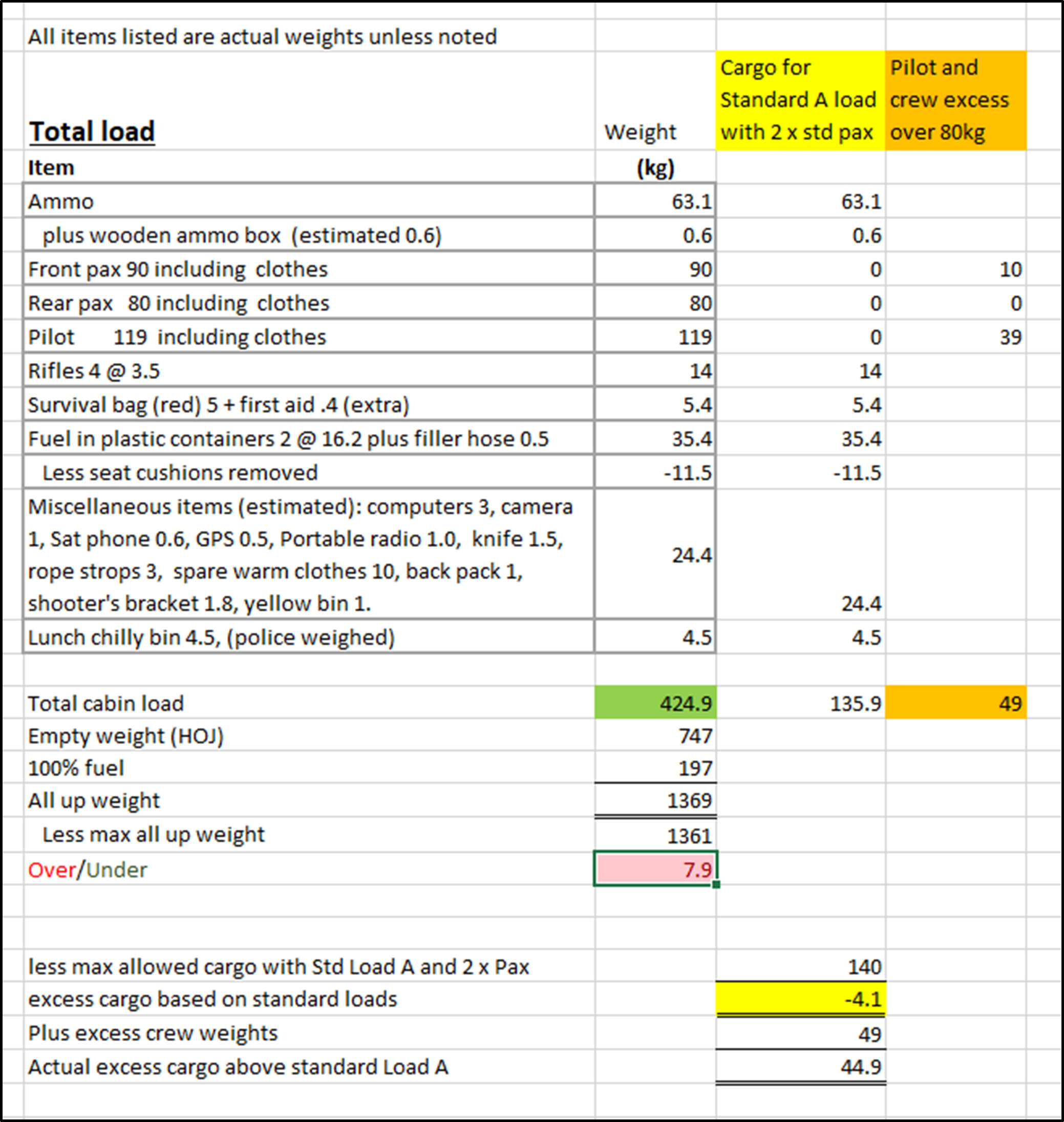

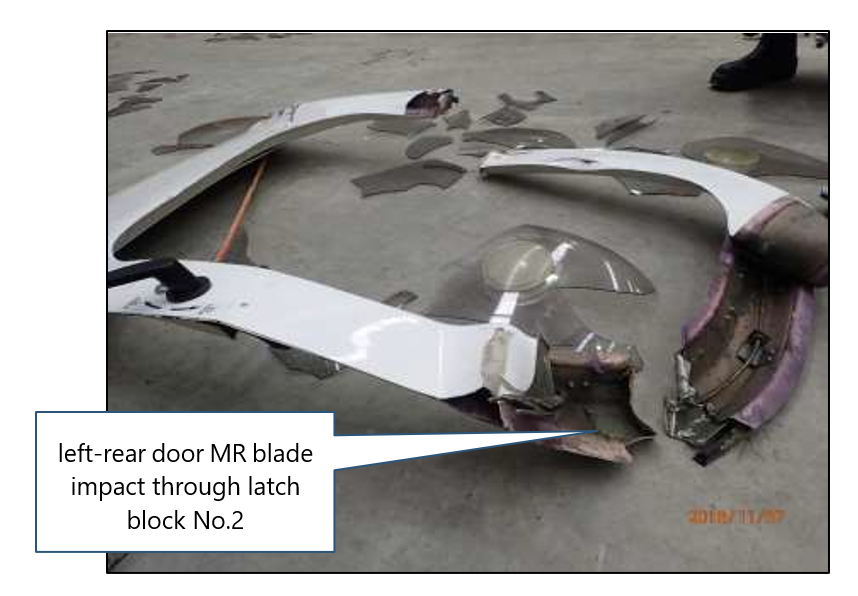

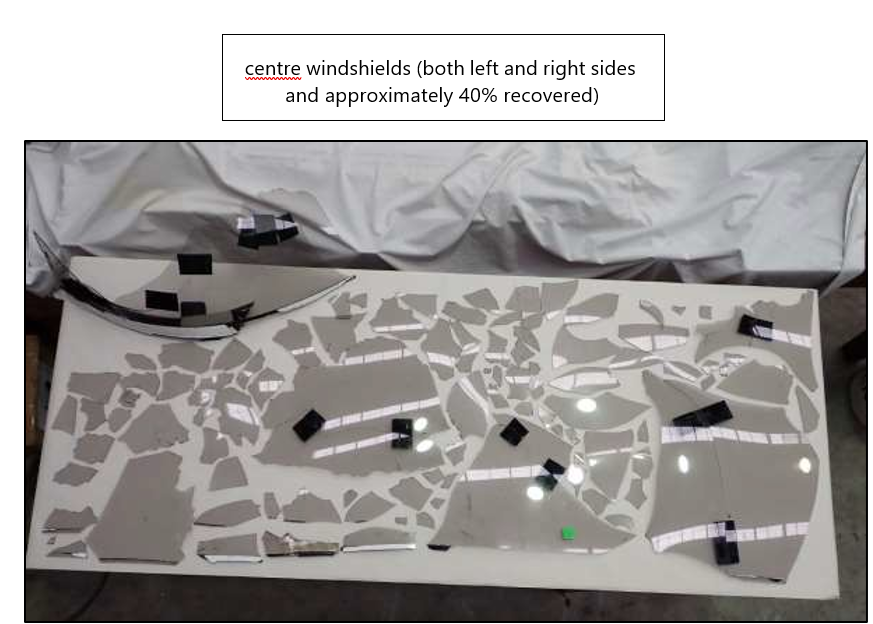

TAIC. (2018). Interim report AO-2018-009: MDHI (Hughes) 369D, Registration ZK-HOJ, Wanaka, 18 October 2018. Wellington: Transport Accident Investigation Commission.

TAIC. (2019). AO-2019-005, BK117-C1, ZK-IMX Controlled flight into terrain (water), Auckland Islands.

US Federal Government. (2021). Electronic Code of Federal Regulation. Retrieved from https://ecfr.federalregister.gov