TAIC identifies safety issues for KiwiRail’s auxiliary generator wagons -- programmed maintenance checks and wagon fire detection alarms. Small fire in auxiliary generator wagon for Capital Connection passenger train, extinguished. Cause was spontaneous ignition of materials around hot exhaust. Circumstances: Corroded exhaust that nobody noticed because inspection wasn’t required and maintenance wasn’t done.

Executive summary Tuhinga whakarāpopoto

What happened

- At about 0602, on 11 May 2022, the Capital Connection express passenger train was at the platform of Palmerston North station when the train manager discovered a fire on board the auxiliary generator wagon.

- All passenger carriages were immediately evacuated before the doors were closed to prevent re-entry.

- The train manager contacted Fire and Emergency New Zealand to report the fire and a fire appliance responded. On arrival firefighters observed a small fire in the auxiliary generator wagon, which they extinguished with a carbon dioxide portable fire extinguisher.

- There were no injuries, and the fire damage was contained to the top box and ceiling of the auxiliary generator wagon.

Why it happened

- The fire was accidental and likely caused by the proximity of the exhaust tail pipe to the internal ceiling lining of the wagon.

- The likelihood of a fire in the auxiliary generator wagon had increased due to a combination of the following factors:

- the top box was sealed closed and could not be opened for maintenance inspection

- the insulation within the top box was in poor condition with significant soot build-up

- the exhaust tail pipe had corroded to the extent that it no longer extended through and above the roof of the auxiliary generator wagon.

What we can learn

- Rail vehicle maintenance must include inspection of all key parts and equipment to minimise the risk of a fire on board a passenger train.

- Early fire detection systems on trains are vital to ensure any fire is detected at the earliest opportunity before spreading throughout the train.

Who may benefit

- All operators, maintenance staff and contractors responsible for auxiliary generator wagons may benefit from the findings from this report.

Factual information Pārongo pono

Background

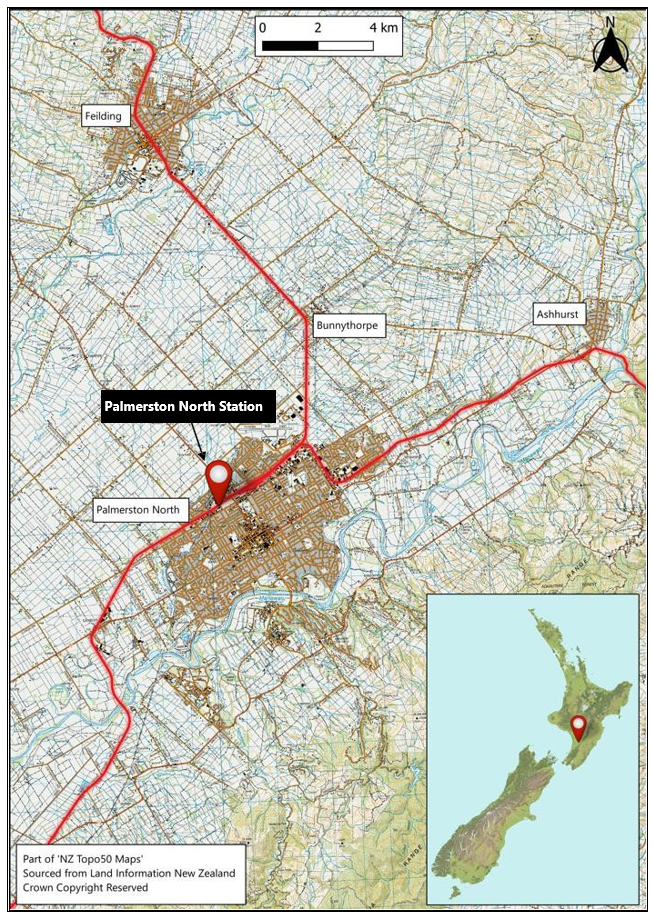

- At the time of this incident, the Capital Connection express passenger train (the Capital Connection) was a long-distance passenger service that operated on weekdays between Palmerston North and Wellington. The service was operated by KiwiRail Holdings Limited (KiwiRail) on behalf of the Greater Wellington Regional Council and the Horizons (Manawatu/Whanganui) Regional Council.

- Between 1971 and 1975, new wagons were imported from South Korea to be used as guards’ wagons. In 1998, Tranz Rail modified six of these wagons and equipped each with an auxiliary generator to provide electrical power for ancillary services, such as air conditioning and saloon lighting, on passenger trains.

- Five of these auxillary generator wagons (AG wagons) remained in operation at the time of this incident. Four were owned by KiwiRail, of which two were leased to other operators (Glenbrook Rail and Dunedin Rail). The fifth AG wagon was owned by Greater Wellington Regional Council and operated by Transdev Wellington.

Narrative

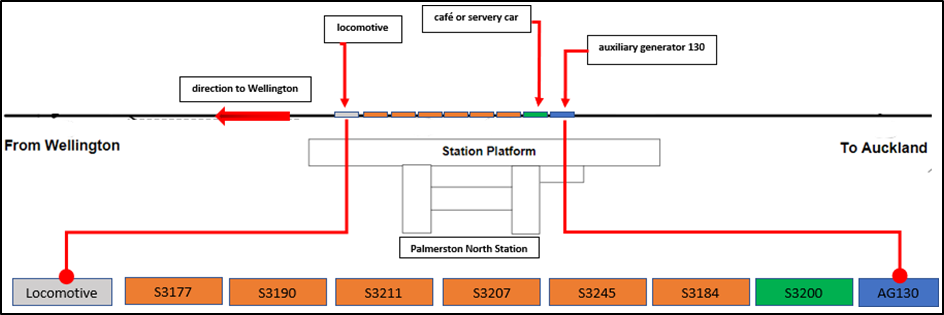

- On Wednesday 11 May 2022, the Capital Connection from Palmerston North to Wellington had a consist of one locomotive attached to seven carriages (six S-class carriages and one serving carriage) and an AG wagon (AG130) at the rear (see Figure 3).

- The train was crewed by a locomotive engineer, a train manager and a train attendant.

- At about 0500, as part of their yard duties to ready the train for service, the train manager entered AG130 at the Palmerston North station to start the auxiliary generator set.

- With the auxiliary generator set running, the train manager connected the power through to the rest of the train using the generator outgoing switch on the control panel.

- After the train manager completed their yard duties, the diesel locomotive arrived and was coupled up to the train. This was followed by a standard brake test before the train was piloted by the train manager to the main platform at Palmerston North station.

- With the train berthed at the platform, the train manager released all external doors in preparation for passengers to board.

- At about 0602, the train manager smelt something they described as a “burn off” (grass burning). The train manager walked to the back of the train to investigate the burning smell and realised it was coming from within AG130.

- Upon entering AG130, the train manager noticed red embers in and around the exhaust silencer enclosure (the top box) of the auxiliary generator set.

- The train manager stopped the auxiliary generator set by activating an emergency engine stop button located on the control panel, before isolating the batteries with the main control circuit breaker.

- The train manager then contacted the locomotive engineer to report the fire and ask the locomotive engineer to alert train control.

- At about 0604 the locomotive engineer notified the national train control centre of the situation at Palmerston North station and then asked train control for the traction overhead power to be switched off.

- The train manager contacted Fire and Emergency New Zealand to report the fire onboard the train.

- The train manager and the train attendant evacuated all passengers and only after confirming that there were no passengers onboard, closed and locked the external doors to prevent re-entry.

- At about 0612 the firefighters arrived and entered AG130 and extinguished a small fire in the top box area with a carbon dioxide portable fire extinguisher.

- There were no injuries to passengers or the train crew. Fire damage was confined to the top box and the ceiling of AG130.

- KiwiRail arranged buses to replace the train service and transport waiting passengers to Wellington.

- The attending fire officer advised the train crew to have AG130 monitored for at least a 24-hour period. They also recommended that AG130 not be operated on the main line at speed during this period, because of the risk of the fire re-igniting.

- The locomotive engineer notified KiwiRail Operations regarding these fire risks. A shunt team was dispatched with a shunt locomotive to uncouple AG130 and take it to the nearby Palmerston North rail yard.

Key personnel information

- The train manager joined KiwiRail as a train manager in 2015 and had been working onboard the Capital Connection since then.

- The locomotive engineer had more than 15 years’ experience driving trains.

- The train attendant joined KiwiRail in 2021.

- The KiwiRail train crew were trained in basic firefighting, this training included the use of portable fire extinguishers. However, as the AG130 was full of smoke and the portable fire extinguishers available were designed to fight small fires, the train crew exercised their judgment and did not attempt to put out the fire themselves.

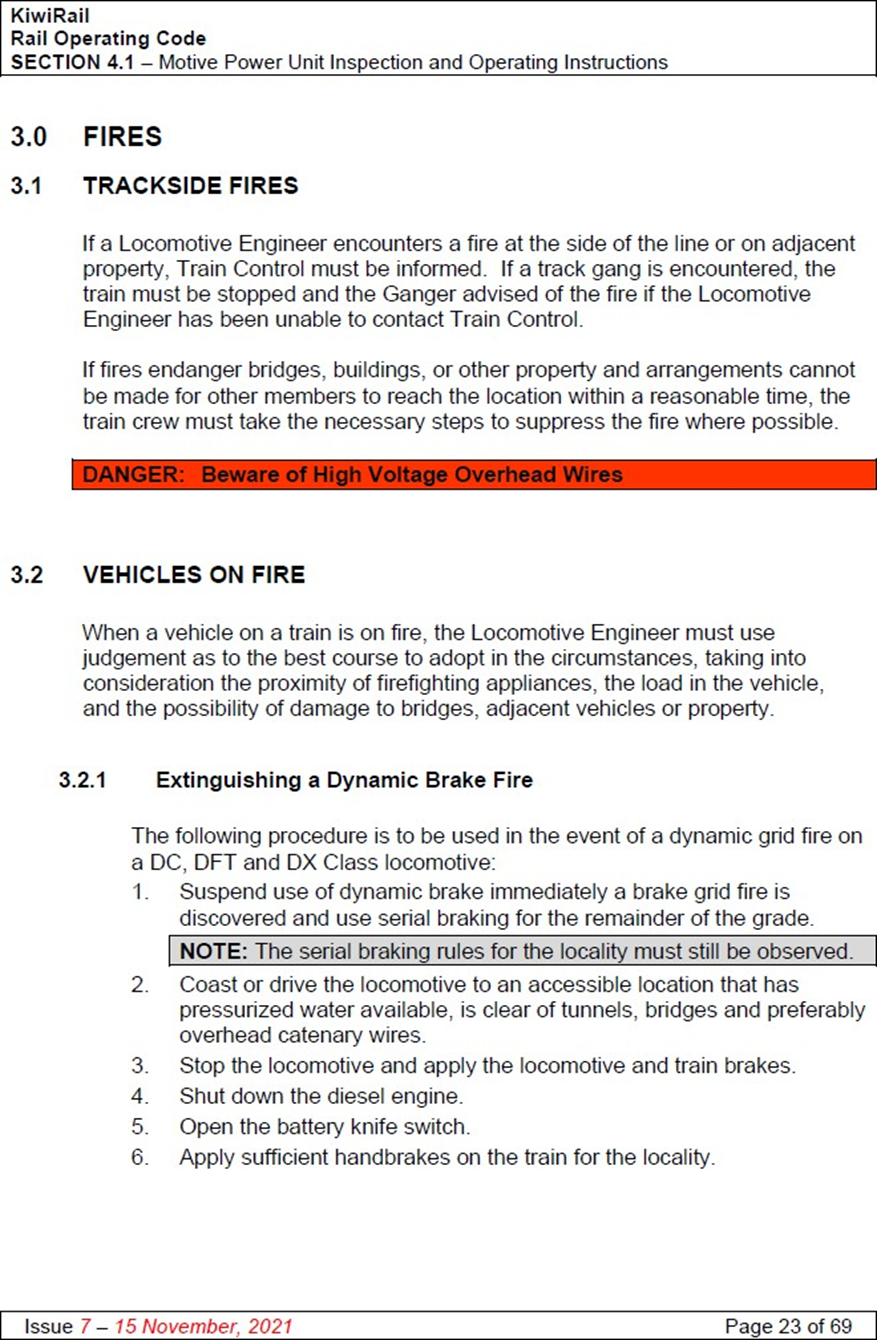

Instructions to train crew in the event of a fire

-

KiwiRail had produced guidelines for the event of a vehicle on fire. Clause 3.2 of Section 4.1 (Motive Power Unit Inspection and Operating Instructions) of the KiwiRail Rail Operating Code (see Appendix 1) states:

When a vehicle on a train is on fire, the Locomotive Engineer must use judgement as to the best course to adopt in the circumstances, taking into consideration the proximity of firefighting appliances, the load in the vehicle, and the possibility of damage to bridges, adjacent vehicles or property.

-

Clause 3.3 of the Code – Fire Precautions – states:

The best protection against fire is cleanliness. This applies particularly to the engine and engine room, the underframe mounted equipment and bogies.

-

At clause 10.1 – Fire, in Section: 11 (Emergency Procedures) of KiwiRail’s Operating

Procedures, it states in part:

Immediate action on discovery:

-

raise the alarm

-

call fire – dial 111

-

attempt to extinguish the fire – use appropriate extinguisher.

Vehicle information

Auxiliary generator wagon 130

- AG130 was owned, operated, and maintained by KiwiRail.

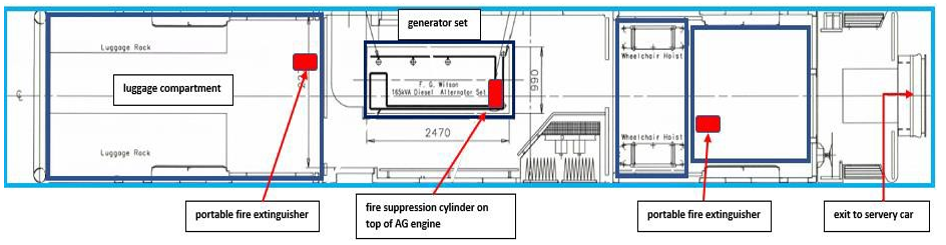

- The purpose of AG130 was to provide electrical power for ancillary services on the passenger section of the train from a 165 kVA (Kilo Volt-Ampere(s)) diesel-fuelled turbo auxiliary generator set. AG130 also provided storage for onboard services and a disabled access facility (a wheelchair ramp).

Fire detection and response

- There were no fire or smoke alarms in AG130.

- AG130 contained a Lifeline 2000 automatic fire extinguisher system (Lifeline 2000) attached to the auxiliary generator set, which was not activated during the incident.

- The Lifeline 2000 was designed to be activated using an insulated, flexible double-link wire fitted within the auxiliary generator set enclosure. Heat generated by a fire would melt the insulation around the link wire and allow the two conductors to make contact, triggering the control unit to activate an explosive charge on a pressurised fire extinguisher bottle. The foam suppressant was ducted to discharge nozzles within the auxiliary generator set enclosure via plastic-coated aluminium tubing.

- Inspection after the fire found that the insulation around the link wire had not melted and remained intact, unaffected by the incident, as would be expected given the location of the fire (see paragraph 3.14).

- AG130 contained two portable 4.5 kilogram dry-powder fire extinguishers, one located in the luggage compartment, and another located at the other end of the wagon (see Figure 4). There was also one portable fire extinguisher in each passenger carriage of the Capital Connection.

- None of the onboard fire extinguishers was used to extinguish the fire.

AG wagon exhaust system

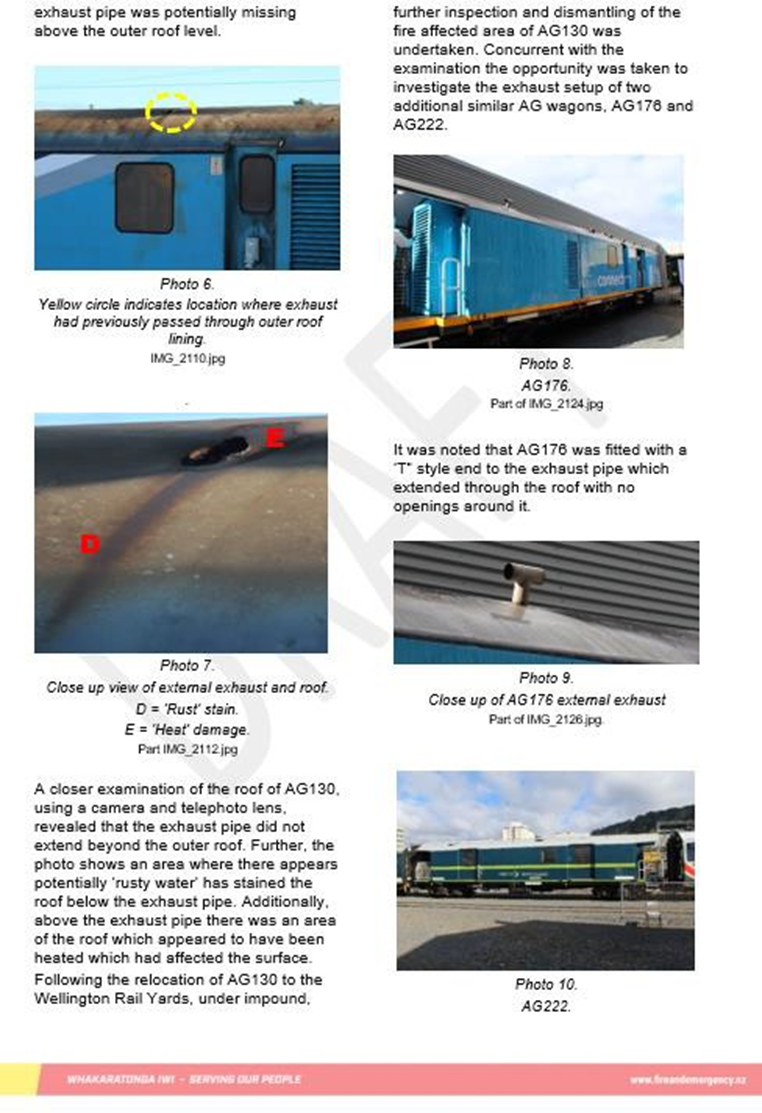

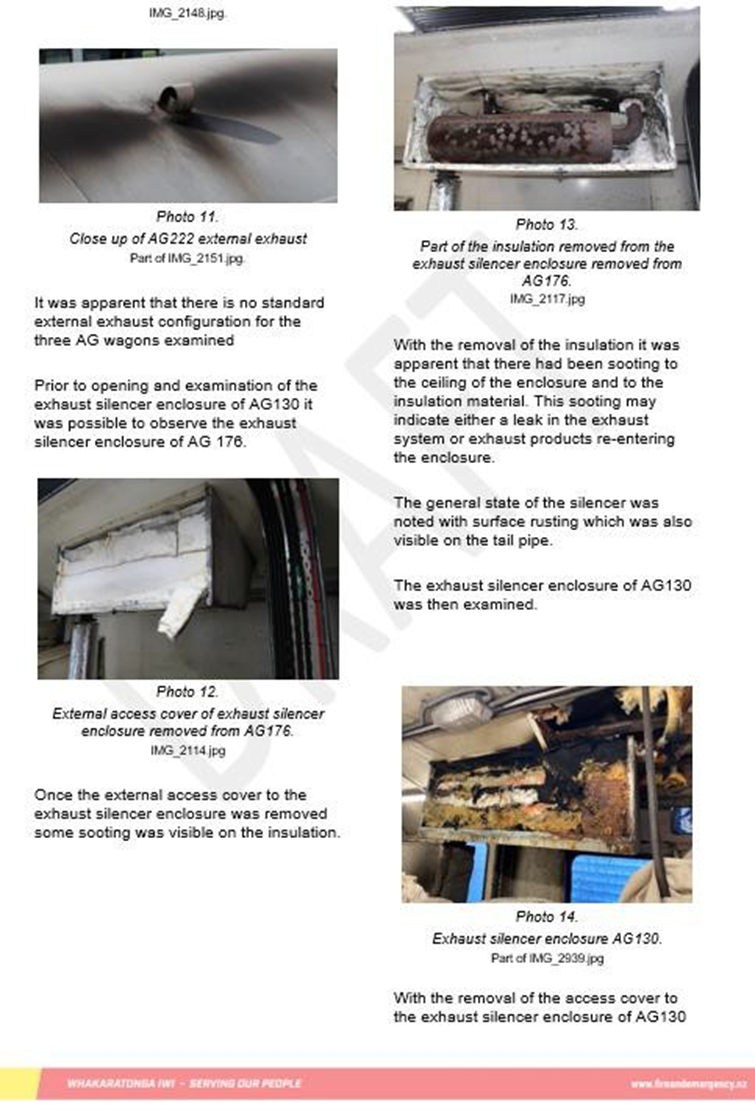

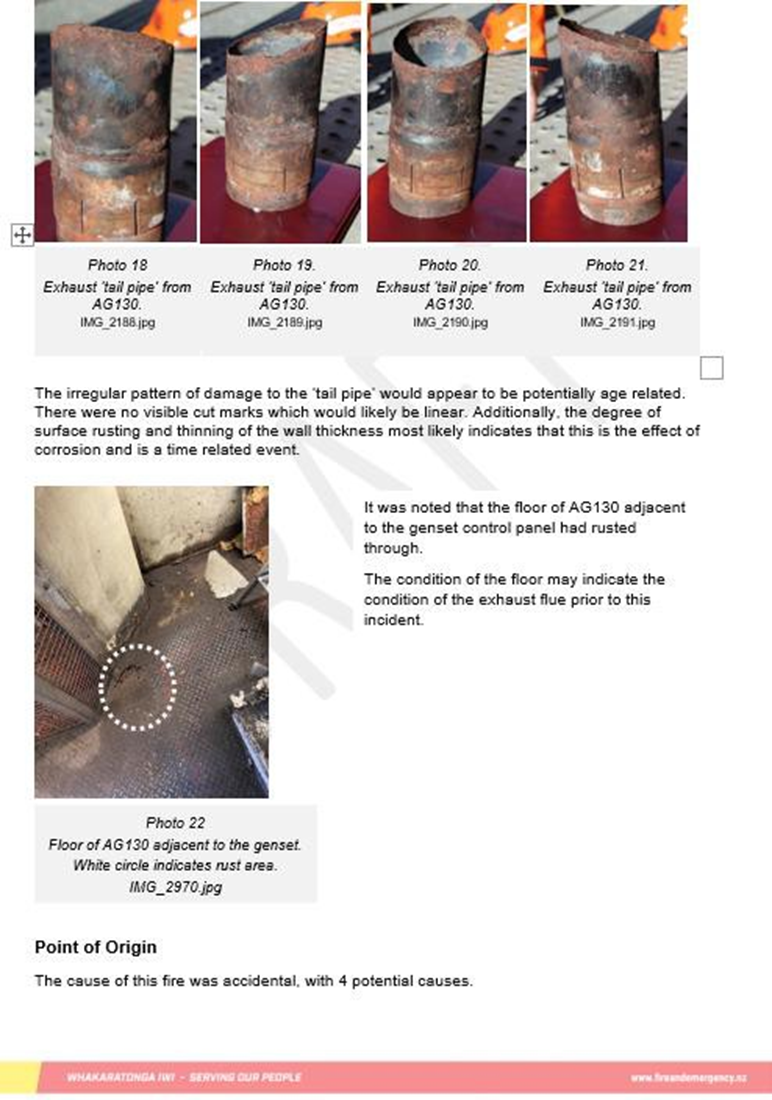

- The Commission inspected the exhaust systems of three AG wagons: AG130, AG176 and AG222. The AG130 and the AG176 were owned by KiwiRail, while the AG222 was occasionally leased by KiwiRail from Greater Wellington Regional Council. The AG130 exhaust system was the only one in which the exhaust tail pipe was missing, so that the auxiliary generator set’s exhaust did not extend up through the top box and out through the roof (see Figure 5).

- The inspection also revealed significant surface rusting and thinning of the AG130 ‘s exhaust tail pipe (see Figure 6).

- When the top boxes of the three AG wagons were opened and inspected the soundproof material in AG130 showed signs of significant soot build-up between the layers (see Figure 7).

AG wagon inspection and maintenance programme

- Before operating rail vehicles on the national rail network, an operator must provide a safety case to Waka Kotahi NZ Transport Agency (in consultation with WorkSafe NZ) to approve. The operator’s rail vehicles must be compliant with the safety system described in that safety case before it can operate on the national rail network.

- The inspection and maintenance of AG wagons was in accordance with KiwiRail’s M2000 Mechanical Code (the Code). The Code required the scheduled maintenance inspection of locomotive-hauled passenger rolling stock (which includes AG wagons) to be carried out by a service manager or team leader at the following intervals:

- Power generator sets – every 500 operating hours with an upper limit of 600 hours. Passenger B-check to be carried out with this service check.

- 1250km maintenance check with an upper limit at 1500km.

- The A maintenance check every 6000 km with an upper limit at 7000 km.

- The B maintenance check every 24000 km or 6 months whichever comes first, upper limit of 26000 km or 7 months whichever comes first.

- The C maintenance check every 12 months with an upper limit of 14 months.

- The 500-hour check on auxiliary generator sets required the following work to be carried out:

- air filters clean or change

- engine oil change

- oil filters change

- fuel lift pump clean strainer and sediment bowl

- fuel filters change

- water filter change

- vee belts check tension and condition

- oil leaks rectify

- test run check idle speed, check intake fans operate OK.

- On 19 April 2021, a 500-hour check was completed on the AG130 auxiliary generator set. The engine hour meter registered 43,967 operating hours.

- On 1 September 2021 (eight months before the incident), a further 500-hour check was carried out. The engine hour meter registered 44,837 operating hours, making this check overdue by 370 hours. KiwiRail advised the Commission that the late scheduling of the check was because of staffing pressures.

- During this check, it was noted that the oil pressure gauge was not working and there was an abnormal alternator output frequency of 50 Hz.

- The most recent A, B and C checks on AG130 were undertaken within the specified timeframes and did not identify any major work to be carried out to either the wheels, braking system, electrical components, or the passenger car coupling system. There was no requirement to inspect the exhaust system or roof area during any of the checks.

Fire investigation

- The fire was confined to the auxiliary generator set enclosure of AG130, affecting the exhaust system and the ceiling of the wagon. There was smoke damage throughout AG130 (see Figure 8).

- The diesel fuel for the auxiliary generator set was contained within a tank under the auxiliary generator set and had not been affected by the fire. Fuel pipes within the auxiliary generator set enclosure remained intact.

- The independent fire investigator engaged by the Commission identified four potential causes of the fire:

- Due to damage to the exhaust ‘tail pipe’ and it not extending above the exterior roof line of the carriage, a spark or sparks from the exhaust entered the space between the exterior roof and the interior ceiling lining igniting the combustible material, plywood, below the outer skin of the wagon

- Due to damage to the exhaust ‘tail pipe’ and it not extending above the exterior roof line of the carriage, whilst parked the exhaust gases have built up in the space between the exterior roof and the interior ceiling lining raising the temperature of the lining and igniting the combustible plywood material, resulting in ignition

- Due to the proximity of the exhaust ‘tail pipe’ to the combustible lining, pyrophoric action17 has led to the ignition of the internal ceiling lining

- Due to the location of the exhaust ‘tail pipe’, radiant heat from the exhaust pipe has ignited the interior ceiling lining.

- The fire investigator determined that there were no electrical faults in the wiring and eliminated electricity as a possible cause of the fire.

- The fire investigator concluded that the most probable cause of the fire was accidental and, because of the proximity of the exhaust tail pipe to the combustible lining, pyrophoric action had led to the ignition of the internal ceiling lining (potential cause 3 above).

Previous occurrences

- Fires in AG wagons are not uncommon because of the presence of a wide range of fuel and ignition sources in the presence of running machinery.

- The Commission has previously investigated several such fires,18 resulting in the following recommendations:

- RO-2004-112: To modify the side shrouds of the DMU ADC cars to improve access to the auxiliary engines (recommendation 008/05, to Auckland Regional Transport Authority)

- RO-2004-116: To take steps to ensure that the cooling airflow is adequate and unrestricted within the generator enclosure around all parts of the diesel engine and the alternator housing, and that there is no build-up of diesel oil or dust particles. (recommendation 069/05, to Toll NZ Consolidated)

- RO-2006-101: To take steps to issue work instructions for maintaining safety-critical equipment and work on safety-critical components is signed off by someone other than the maintainer and all maintenance is recorded (recommendation 015/07, to Land Transport NZ).

Analysis Tātaritanga

Introduction

- The following section analyses the circumstances surrounding the event to identify those factors that increased the likelihood of the event occurring or increased the severity of its outcome. It also examines any safety issues that have the potential to adversely affect future operations.

How the fire occurred

-

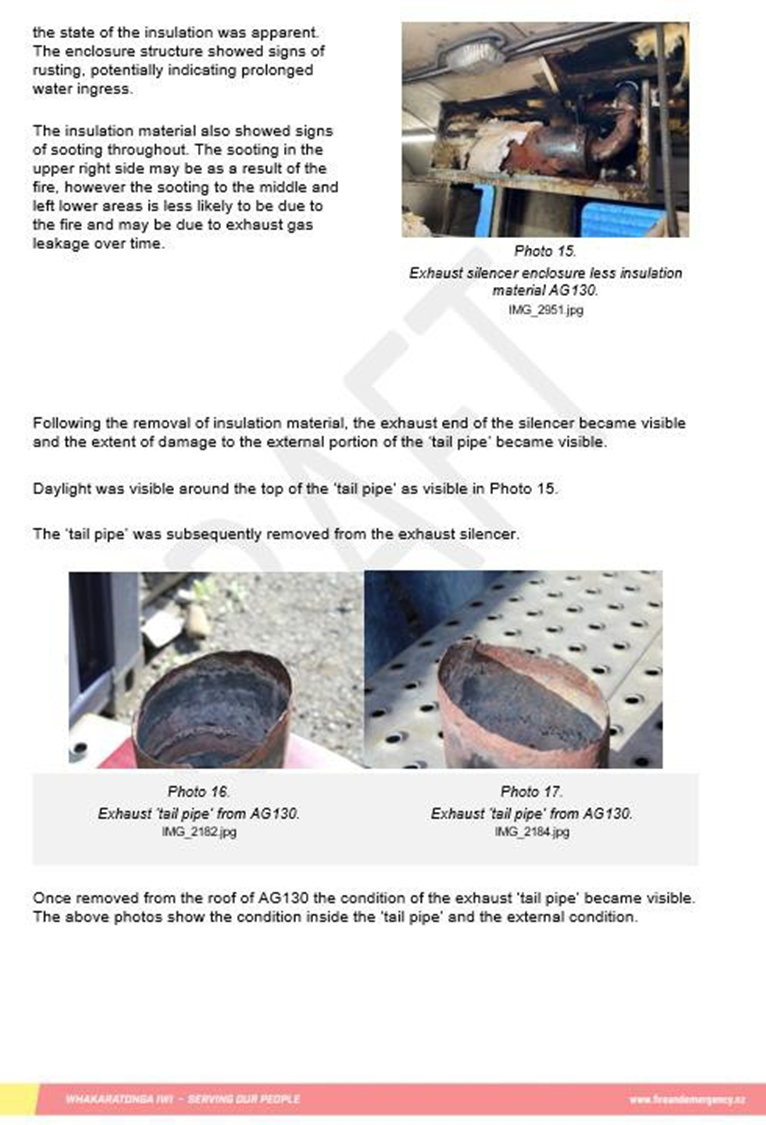

Commission investigators inspected the exhaust systems of three different AG wagons, including the AG130. Investigators found that the AG130 exhaust tail pipe no longer extended through the ceiling, and daylight was visible from inside the wagon (see Figure 9).

Figure 9: Daylight visible where exhaust tail pipe met ceiling of AG130 - The degree of surface rusting and thinning of the exhaust tail pipe wall thickness indicated it is very likely that the damage was age related.

- When the top box of AG130 was opened, investigators found the insulation material was in poor condition and contained a significant amount of soot. Although soot deposits in the top right of the top box may have been produced during the fire, it is almost certain that those in the centre and lower left of the top box were formed before the fire.

- The independent fire investigator engaged by the Commission determined that the fire in AG130 was accidental (see Appendix 3: Fire Investigation Report), They also determined that the fire was likely caused by pyrophoric action (arising from the proximity of the exhaust tail pipe to the combustible lining) leading to the ignition of the internal ceiling lining.

- In fire investigation terms, pyrophoric action refers to fires that have started in confined spaces, where long-term exposure to a source of heat causes carbon deposits such as charcoal and soot to form. A sudden influx of air, arising from degradation of the surrounding area, could cause these carbon deposits to ignite (Icove D.J. & Haynes G.A. (2017). Kirks Fire Investigation, 8th edition. Referenced by independent fire investigator’s report (see Appendix 3)).

- It is virtually certain that the likelihood of a fire on board AG130 increased because of a combination of the following factors:

- the insulation within the top box was in poor condition, containing soot build-up

- the exhaust tail pipe had corroded and did not extend through and above the roof of AG130

- the top box was sealed closed and could not be opened for maintenance or inspection.

Inspection and maintenance

Safety issue: The programmed maintenance checks of the AG wagon were inadequate and did not include inspection of the exhaust system or of the roof. This increased the risk of fire from exhaust systems in poor condition.

- KiwiRail’s M2000 Mechanical Code stipulates the scheduled maintenance inspection intervals. The wagon schedule inspection systems are further detailed in the Wagon Inspection Manual M9202/01.

- Because of staffing pressures, one of the 500-hour checks on AG130 was 370 hours overdue when it was carried out, but this had no bearing on the incident.

- As part of the scheduled maintenance there was no requirement to inspect the top box or the roof of the wagon where the tail pipe should have extended through.

- It is virtually certain that had the maintenance programme for AG130 included inspection of the auxiliary generator set exhaust system and the top box, the poor state of both the insulation and the tail pipe would have been identified.

Onboard fire detection system

Safety issue: All wagons should contain detection systems capable of alerting train crew and passengers to smoke or fire in any area within the wagon.

- The auxiliary generator set within AG130 was fitted with a Lifeline 2000 automatic fire extinguisher system. However, that system did not include an audible alarm or other alert mechanism to warn the train crew or the passengers of a fire. Further, there were no other fire or smoke alarms within AG130.

- The Lifeline 2000 fire extinguisher system was configured to detect and extinguish a fire in or on the auxiliary generator set. A fire within the wagon, but away from the auxiliary generator set, would not activate the system until the heat of the fire was such that the insulation around the link wire melted. The fire in the ceiling of AG130, around the exhaust tail pipe, had not yet reached the temperature required to melt the link wire insulation and activate the fire extinguisher system.

- Given the fire was detected by the train manager smelling the smoke, it is very likely that a smoke detector would have warned the train crew of the fire at an earlier stage.

- The AG wagon is the last vehicle in the consist when travelling south to Wellington from Palmerston North. Had this train service departed with the fire undetected, it is likely that the fire would have remained undetected for some time. The Capital Connection travels through seven tunnels, two of which are over 1.2 kilometres long. A train on fire is an extremely dangerous situation, travelling through a tunnel would further exacerbate the seriousness of the situation as fire spreads more quickly in the confined space and evacuating passengers and crew away from the danger is more difficult.

- In this incident, the fire was detected at a time when it was small enough for a Fire and Emergency New Zealand crew to attend and to extinguish it with a portable extinguisher. However, if the fire had continued and grown or occurred in an isolated location, the risk of more extensive damage to the train and danger to passengers and train crew would be far greater.

- The loss of life and extent of property damage caused by a fire can be minimised by ensuring early detection, thus allowing appropriate action to be taken.

- Although new passenger trains are designed and equipped with onboard fire detection systems, neither the “S” class carriages nor AG wagon had any fire detection systems installed.

- A recommendation has been made to KiwiRail to address this safety issue (see para 6.3).

Findings Ngā kitenga

- It is virtually certain that the likelihood of a fire on board AG130 increased because of a combination of the following factors:

- the insulation within the top box was in poor condition, containing soot build-up

- the exhaust tail pipe had corroded and did not extend through and above the roof of AG130

- the top box was sealed closed and could not be opened for maintenance inspection.

- It is virtually certain that had the maintenance programme for AG130 included inspection of the auxiliary generator set exhaust system and the top box, the poor state of both the insulation and the tail pipe would have been identified.

- It is very likely that a smoke detector would have warned the train crew of the fire at an earlier stage.

- The train crew took appropriate action on discovering the fire, evacuating the passengers and minimising the danger to passengers and crew.

Safety issues and remedial action Ngā take haumanu me ngā mahi whakatika

General

- Safety issues are an output from the Commission’s analysis. They typically describe a system problem that has the potential to adversely affect future operations on a wide scale.

- Safety issues may be addressed by safety actions taken by a participant, otherwise the Commission may issue a recommendation to address the issue.

Maintenance checks

Safety issue: The programmed maintenance checks of the AG wagon were inadequate and did not include inspection of the exhaust system or of the roof. This increased the risk of fire from exhaust systems in poor condition.

-

In August 2022, KiwiRail informed the Commission that

The 12 monthly maintenance check for the Capital Connection fleet including AG vans was updated in August 2022 to include the following:

- Check motor generator exhaust extends above the roof

- Check motor general exhaust rain flap is working

- Open muffler compartment every year ending with 0 or 5 e.g. (2025 or 2030)

- Inspect muffler, and exhaust pipe condition for damage, holes, corrosion, signs of exhaust leaks

The 1250 km maintenance check for the fleet was updated in October 2022 to include:

- Check exhaust system and muffler box for signs of exhaust leakage, i.e. signs of soot.

- Check for fuel, water and oil leaks.

- The Commission considers these safety actions have addressed the safety issue identified, and therefore no recommendation has been made.

Wagon fire detection alarms

Safety issue: All wagons should contain detection systems capable of alerting train crew and passengers to smoke or fire in any area within the wagon.

-

On 28 September 2023, KiwiRail informed the Commission:

The two AG vans (AG130 and AG176) have been replaced in service in July 2023 by

SRG class generator/passenger carriages that are equipped with trainlined fire detection systems. The Kiwirail AG vans are currently on a stabling check regime pending probable disposal and are used only in exceptional circumstances.

KiwiRail suggests that a more suitable recommendation could be for owners and rail operators (licence holders) of this class of wagon to ensure that any AG vans returned to or used in regular or permanent service to be first equipped with suitable smoke and fire detection systems.

- The Commission acknowledges KiwiRail no longer regularly operates either AG130 or AG176. However, while KiwiRail retain the AG wagons for use, albeit in exceptional circumstances, the safety issue remains. Therefore, the Commission has made a recommendation in Section 6 to address this issue.

Recommendations Ngā tūtohutanga

General

- The Commission issues recommendations to address safety issues found in its investigations. Recommendations may be addressed to organisations or people and can relate to safety issues found within an organisation or within the wider transport system that have the potential to contribute to future transport accidents and incidents.

- In the interests of transport safety, it is important that recommendations are implemented without delay to help prevent similar accidents or incidents occurring in the future.

New recommendation

- On 25 October 2023, the Commission recommended that KiwiRail install smoke and fire detection systems in all auxiliary generator wagons in service to alert train crew and passengers to a fire at the earliest opportunity. (039/23)

-

On 13 November 2023, KiwiRail replied:

This recommendation is accepted and implemented.

KiwiRail no longer have any auxiliary generator wagons in service, since the two AG vans operating on Capital Connection have been replaced by SRG class carriages. All generator cars in use have fire mitigations in place that address the intent of this recommendation. If we do return any AG vans to service at any point in the future then we will make the necessary modifications to fire detection systems before doing so.

Key lessons Ngā akoranga matua

- Rail vehicle maintenance inspections must encompass all key parts and equipment to minimise the risk of a fire on board a passenger train.

- Early fire detection systems on trains are vital to ensure any fire is detected at the earliest opportunity and contained.

Data summary Whakarāpopoto raraunga

Details

Conduct of the inquiry He tikanga rapunga

- On 11 May 2022, the rail regulator notified the Commission of the occurrence. The Commission subsequently opened an inquiry under section 13(1) of the Transport Accident Investigation Commission Act 1990 and appointed an investigator-in-charge.

- Two Commission investigators arrived at Palmerston North rail yard, where AG130 was secured, late in the afternoon of 11 May 2022.

- On 11 May 2022, the Commission engaged an independent fire investigator to assist in determining the cause of the fire.

- The Commission interviewed witnesses on 12 May 2022.

- Two Commission investigators visited KiwiRail Wellington freight depot on 13 May 2022 to examine two other AG wagons.

- Three Commission investigators visited the KiwiRail Wellington freight depot on 24 May 2022 to re-examine AG130 and gather further evidence.

- The Commission carried out further interviews on 30 May 2022.

- On 22 August 2023 the Commission approved a draft report for circulation to four interested parties for their comment.

- The Commission received four responses, of which two were submissions and two had no comment. Changes as a result of these have been included in the final report.

- On 25 October 2023, the Commission approved the final report for publication.

Appendix 1. KiwiRail Rail Operating Code

Appendix 2. KiwiRail Operating Procedures

Appendix 3. Fire Investigation Report

Related Recommendations

On 25 October 2023, the Commission recommended that KiwiRail install smoke and fire detection systems in all auxiliary generator wagons in service to alert train crew and passengers to a fire at the earliest opportunity.