People can make safety-critical errors when they take risks due to focusing too much on completing a job task. Safety-critical tasks should be designed so that it is easy to get the job done safely. TAIC reports on why a worker remote-controlling a shunt locomotive received serious injuries, caught between wagons on board the rail ferry Aratere.

Executive summary Tuhinga whakarāpopoto

What happened

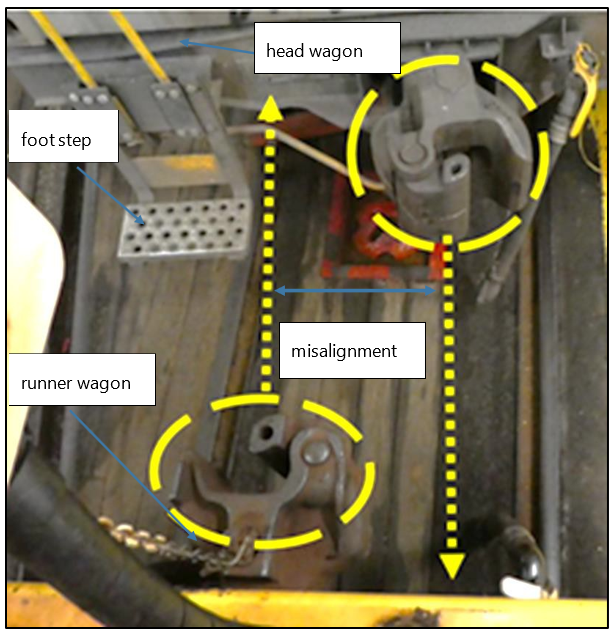

- On the evening of 9 April 2021, a remote-control operator operating a remotely controlled shunt locomotive was injured during discharging operations on board the rail ferry Aratere. The remote-control operator was caught between the foot step of the head wagon and the runner wagon while attempting to couple to the wagons. The head wagon was the first of a set of coupled wagons (a rake) located on the starboard outer track of the Aratere’s rail deck.

- The remote-control operator had made multiple unsuccessful attempts to couple the two wagons. The position of the two wagons on a curved section of the outer starboard track had caused a misalignment of the two couplers. During the final attempt the remote-control operator moved between the two wagons to physically open the knuckle of the couplers, but did not relocate to a safe area before operating the shunt locomotive remotely.

Why it happened

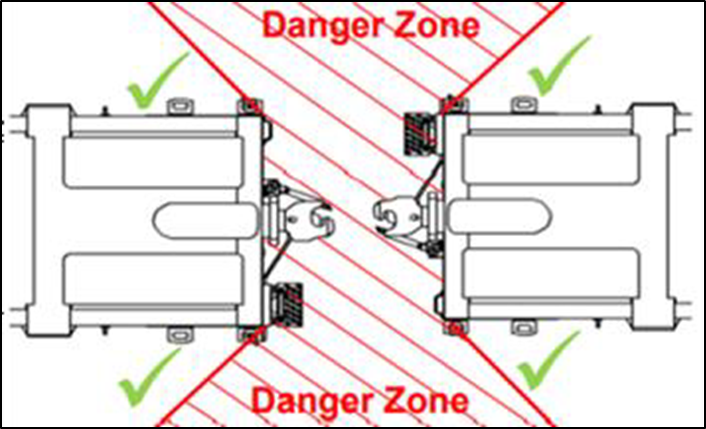

- The Transport Accident Investigation Commission (the Commission) found that the remote-control operator entered the danger zone (an area in which individuals are exposed to physical risk) to realign an off-centre coupler, but did not reposition clear of the danger zone before they operated the shunt locomotive remotely.

- The Commission found that the degree of track curvature on the starboard outer track on the Aratere made it difficult to couple wagons positioned on parts of the curve.

- The Commission found that the risk assessment undertaken to determine the maximum rake length on the outer rails had not adequately mitigated the difficulty involved with coupling wagons positioned on the curved part of a track.

What we can learn

- Shunting rail vehicles is a safety-critical task. Safety-critical tasks should be designed in such a way so as not to cause additional or unnecessary risks for employees.

- Experiencing difficulties with a procedure can lead to task fixation. This can create an environment conducive to risk-taking activity and error-producing conditions.

Who may benefit

- Rail operators and operational staff involved in shunting activities may benefit from this report.

Factual information Pārongo pono

Background

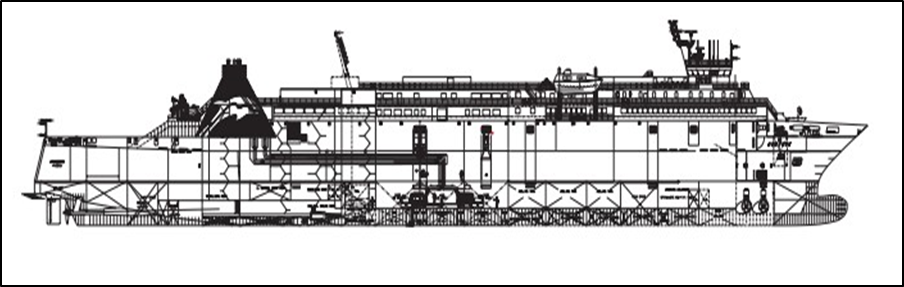

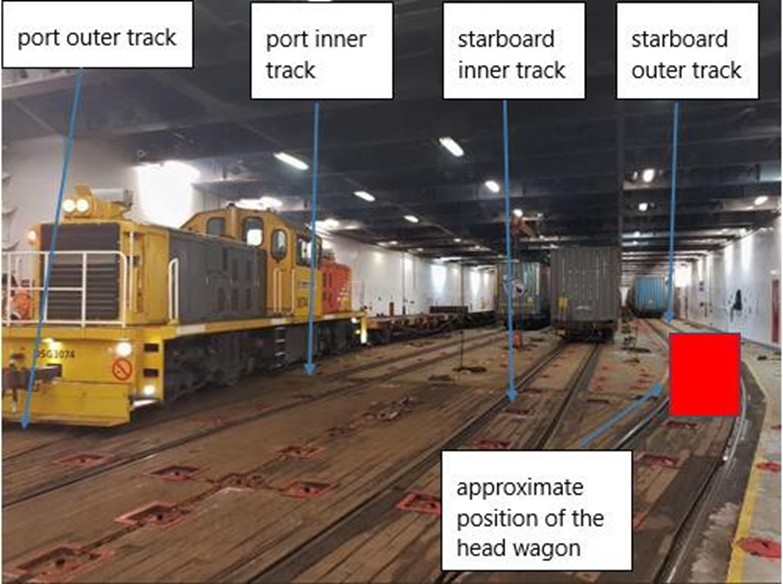

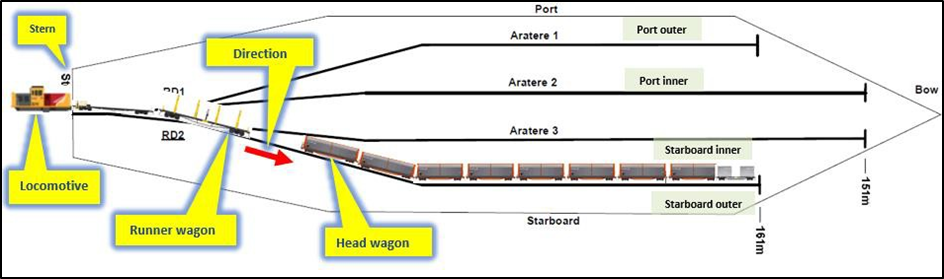

- The Aratere is a rail ferry that can carry up to 32 rail wagons on its lower cargo deck (the rail deck). The rail deck has four rail tracks; the two inner tracks are straight and the two outer tracks are curved at the stern (back) end of the vessel.

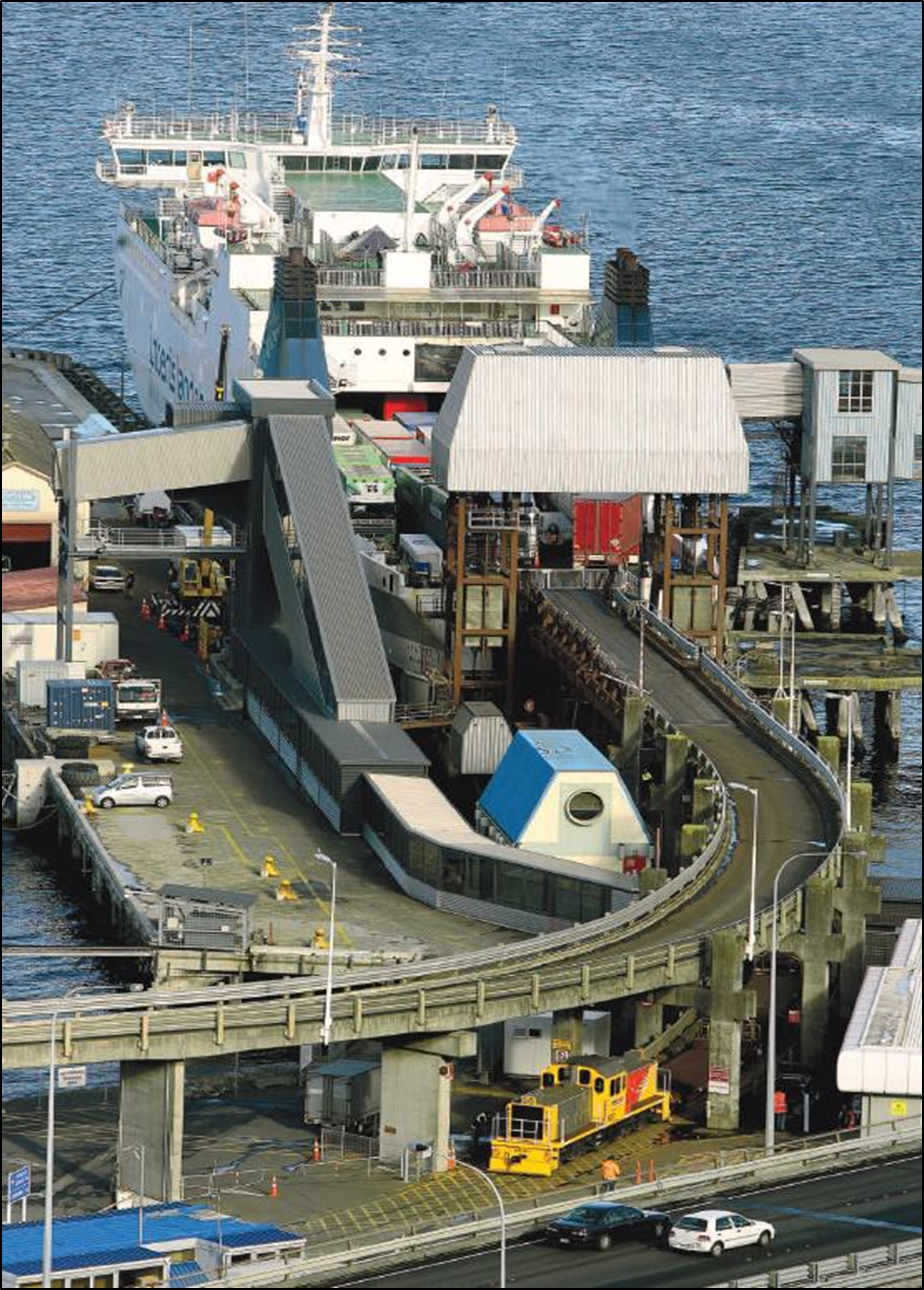

- At the time of the accident, the Aratere had just berthed in Wellington after completing a scheduled voyage from Picton to Wellington.

Narrative

- At 2013 on 9 April 2021, the Aratere departed Picton with four rakes of freight wagons, consisting of two long rakes on the outer tracks and two shorter rakes on the inner tracks.

- A two-person KiwiRail shunting team consisting of a remote-control operator (RCO) and a rail operator (RO) were tasked with discharging and loading rail wagons from the Aratere after it berthed in Wellington. The shunt team was assisted by a certified train examiner positioned at the forward end of the rail deck (see Figure 3).

- The ferry arrived in Wellington at 2315.

- At about 2320 the shunt team received clearance from the ferry crew at the linkspan to enter and commence shunting operations.

-

Once on board, the shunt team set about their first task of removing the long outer rake from the starboard side. Due to the length of this rake (134 metres), the head wagon was positioned on a curved part of the track on the rail deck (see Figure 5).

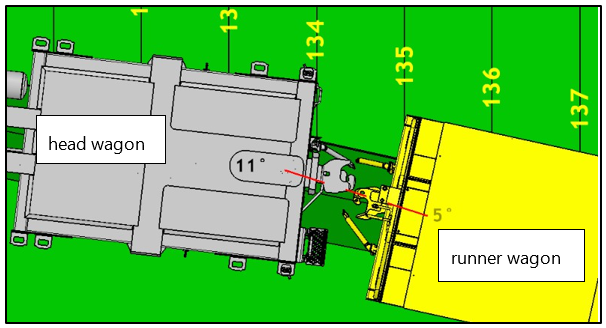

- The curvature of the track caused a misalignment between the coupler on the runner wagon and the coupler on the head wagon on the rake (see Figures 4, 5 and 6).

- The RCO made multiple attempts to couple the wagons. After every unsuccessful attempt the RCO did an ‘out short’6 and went between the wagons to physically realign the couplers and open the knuckles of the couplers of both wagons before the next coupling attempt.

- On the seventh attempt to couple the wagons, the RCO remotely operated the shunt locomotive to move the runner wagon towards the rake, without retreating to the safe zone. The couplers were still misaligned and glanced off each other, resulting in the runner wagon moving further forward than expected (see Figure 7).

- The RCO’s position between the two wagons meant his right leg was jammed forcibly between the runner wagon and the foot step of the head wagon.

- The RCO suffered a serious injury to their leg and was subsequently admitted to hospital for treatment.

Personnel information

- The RCO had achieved certification for remote-control locomotive operations within Wellington station limits on 24 November 2020. Since certification they had had two safety assessments while remotely controlling a shunt locomotive. Neither of these assessments involved shunting on board the Aratere ferry. The RCO was also a certified rail operator and had approximately 20 years’ experience in that role.

- The RCO was qualified to operate the EUF-class runner wagon (see paragraphs 2.19 – 2.22).

- The RO had gained their certification on 21 November 1996 and had been a qualified RCO since 2005.

- The train examiner had been qualified for shunting duties since 27 November 2020.

- The investigation found no evidence of any medical issue with the shunt crew that may have contributed to this accident. The investigation found no evidence that either the relief RCO or the RO were likely fatigued during their shift.

Train/Vehicle information

- The diesel-powered DSG-class shunt locomotive was 12.5 metres long and weighed 56 tonnes. The locomotive was operated remotely by the RCO using a remote-control pack worn in a harness in front of them. The RCO controlled the movement of the locomotive by entering commands into the control pack. These commands were transmitted by radio to the locomotive (see Figure 8).

EUF-class runner wagon

- Runner wagons are attached to a locomotive when shunting rail wagons on board the Aratere. The runner wagons allow the locomotive to remain outside the ferry so that the rail deck is kept free of exhaust fumes.

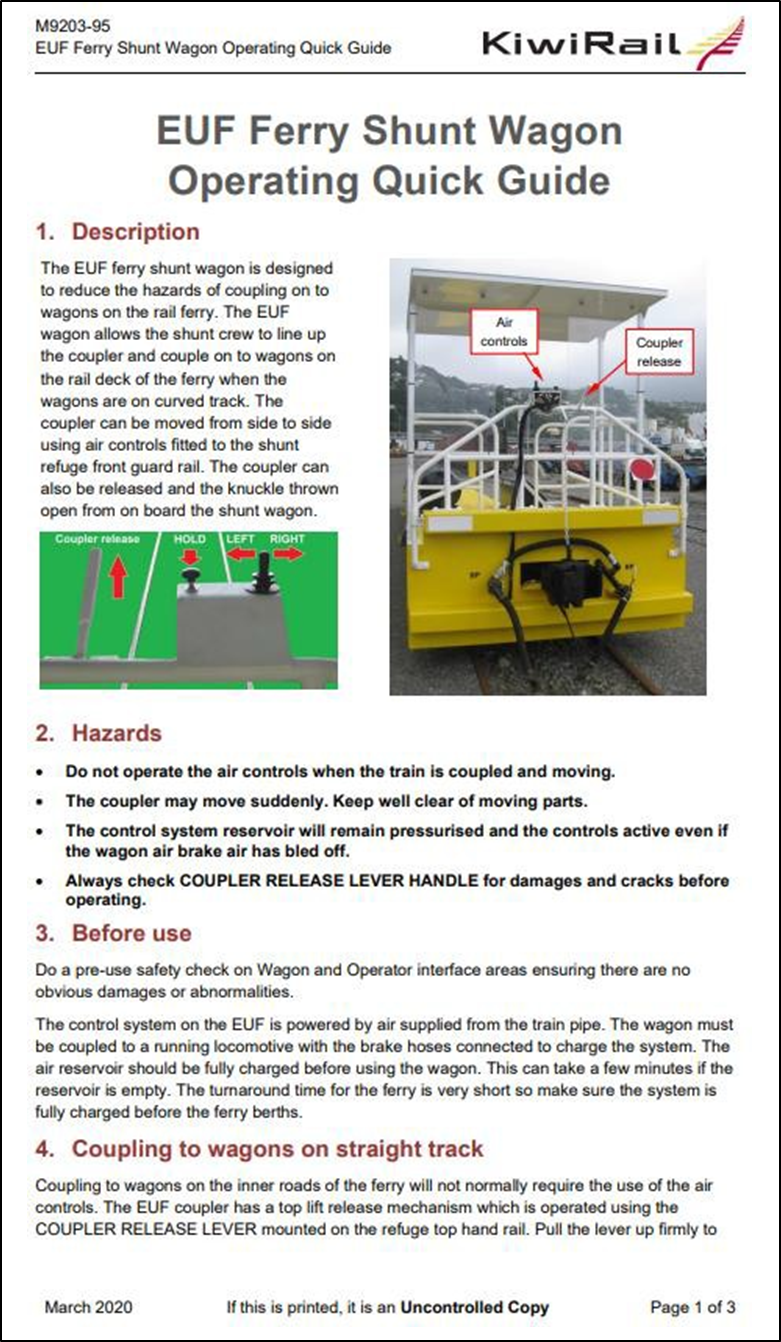

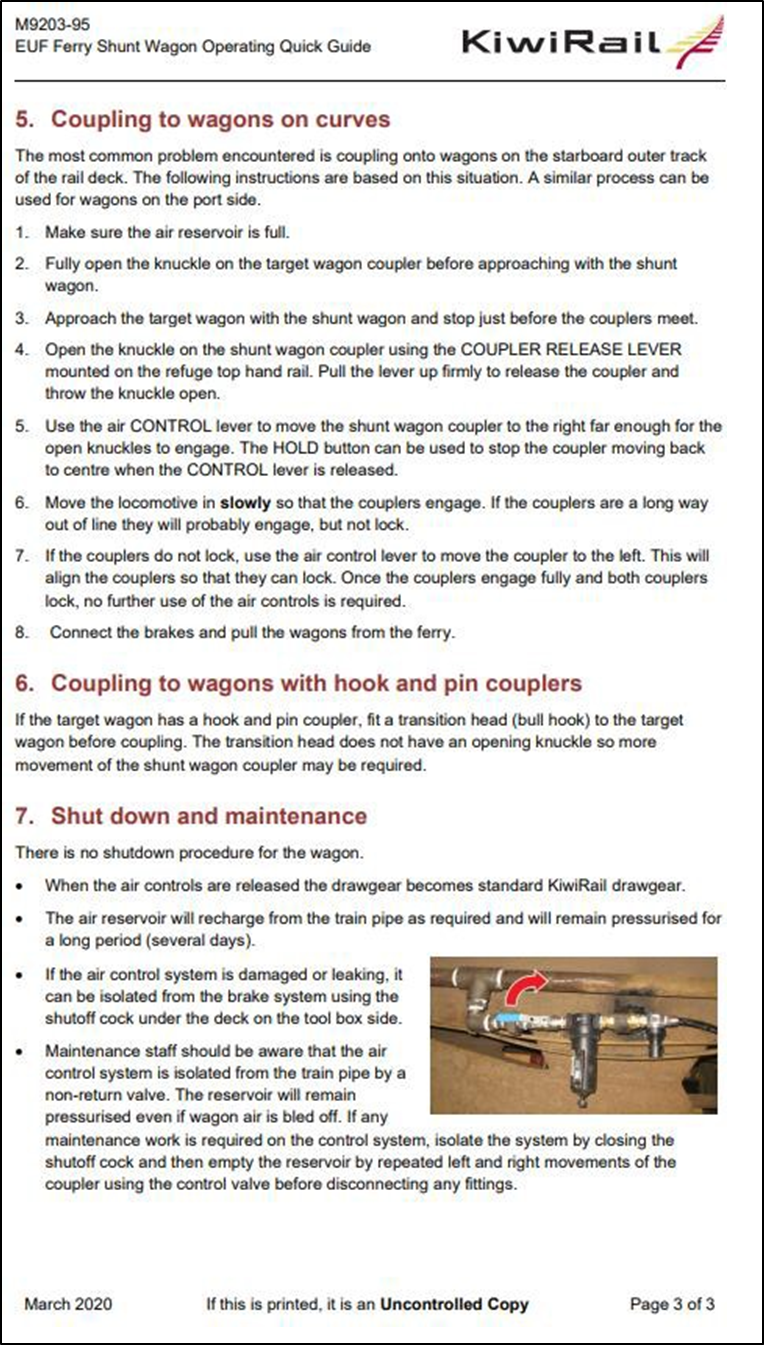

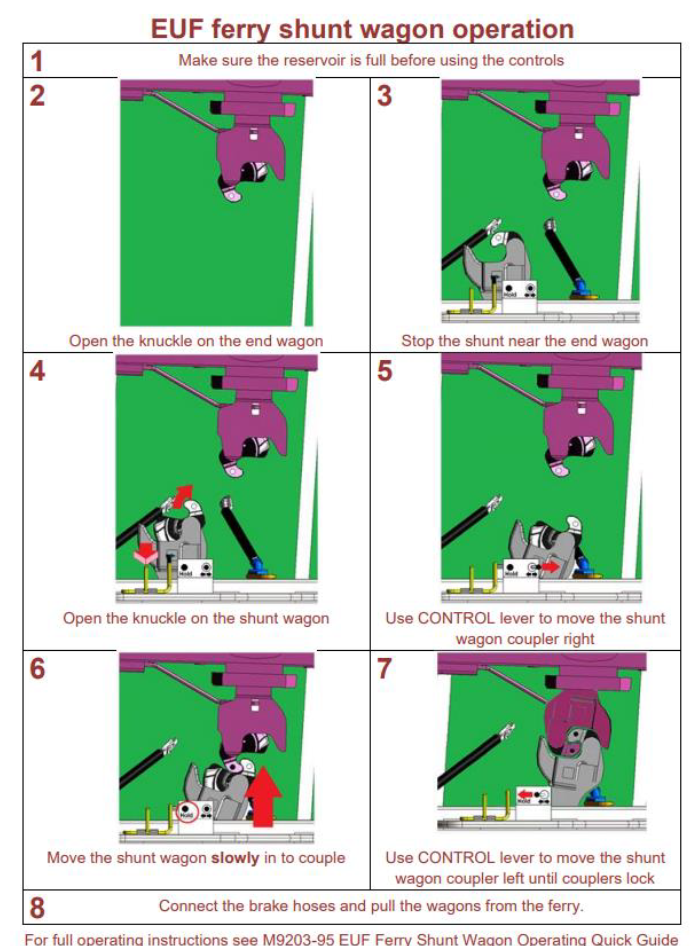

- The EUF-class runner wagon was developed by KiwiRail in 2015. It has an automatic knuckle coupler that was modified so that it could be moved more easily from side to side using the wagon’s air pressure. In addition, the coupler has a top lift release mechanism that can be manually operated from a safe ride position on the wagon deck.

- The EUF-class runner wagon was designed to:

- reduce the need for operating staff to work in the unsafe spaces between wagons (danger zones) when coupling and uncoupling

- provide enough sideways movement on the coupler to allow its open knuckle to engage the open knuckle on the head wagon

- provide enough centring force to bring the couplers into alignment for locking.

- The operation of the runner wagon is described in Appendix 1, EUF Ferry Shunt Wagon Operating Quick Guide.

Aratere Interislander ferry

- The diesel electric vessel Aratere is a roll-on/roll-off rail and vehicle ferry operated by KiwiRail. The vessel has an overall length of 183.5 metres, with the capacity to carry 670 passengers, 230 cars or 30 trucks on the vehicle deck and up to 32 wagons on the four-track rail deck.

Ferry marshalling yard Wellington

- The ferry marshalling yard consists of five railway tracks (see Figure 9).

- KiwiRail is both the network access provider and the rail operator and is licensed by Waka Kotahi NZ Transport Agency for its rail activities.

Recorded data

- The DSG-class shunt locomotive was fitted with a data-recording system known as Tranzlog. The downloaded data was obtained by the Transport Accident Investigation Commission (the Commission) for analysis.

Previous occurrences

- The Commission requested and received incident data from KiwiRail regarding shunting issues on board the Aratere rail ferry. The difficulties associated with coupling to wagons have been a known issue since 2012, when new wagon classes were introduced and automatic knuckle couplers were retrofitted to the existing wagon fleet. The last recorded problem with coupling to the outer starboard rake of the Aratere was in March 2020.

Loading and discharging operations

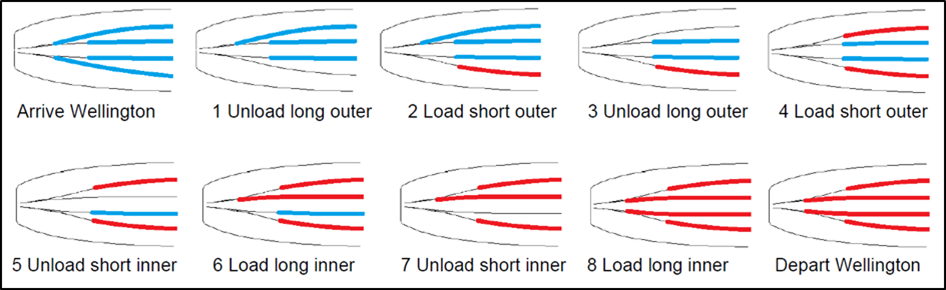

- The loading and discharging sequence was set out in the Aratere Loading and Discharging Manual (the Manual).

- The Aratere’s loading and discharging sequences in Wellington and Picton are different to facilitate efficient access to the rail deck during loading and discharging operations. The sequence is described in section 10.9 of the Manual. The procedure for Wellington is shown in Figure 10. Blue indicates the rakes unloaded at Wellington and red indicates the rakes loaded at Picton. In summary, the Aratere berths at Wellington with the long rakes on the outer tracks and the shorter rakes on the inner tracks. The loading plan for Picton is the reverse, with the longer rakes secured on the inner tracks and the shorter rakes on the outer tracks.

KiwiRail Operating Code, Section 5.1, Shunting Procedure

-

The following is an excerpt from the KiwiRail Operating Code, Section 5.1 regarding the procedures for shunting:

Introduction:

The instructions contained in this section provide for safe shunting practices and are based on knowledge and experience.

Shunting involves the moving and assembling of vehicles making maximum use of the motive power with the least number of movements while ensuring the safety of rail personnel and equipment.

Personal safety 3.1 p11 (effective date 06.10.2019)

When connecting vehicles equipped with automatic couplers don’t stand between the vehicles, or the locomotive and vehicle while they come together. There is insufficient clearance and you may be crushed.

Analysis Tātaritanga

Introduction

- The shunt team discharging freight wagons from the Aratere experienced difficulties connecting the runner wagon to the head wagon on the outer starboard track, because it was positioned on a curved section of the track.

- After several failed attempts to couple the wagons, the RCO entered the danger zone to realign the couplers manually. Prior to their repositioning to a safe area, the RCO operated the shunt locomotive, resulting in their leg being caught between the headstock of the runner wagon and the foot step of the head wagon.

- The following section analyses the circumstances surrounding the event to identify those factors that increased the likelihood of the event occurring or increased the severity of its outcome. It also examines any safety issues that have the potential to adversely affect future operations.

Shunting on board the Aratere

- The automatic knuckle couplers fitted to freight wagons are designed for shunting on straight or near-straight track. Difficulties can occur when personnel attempt to couple wagons on tightly curved track. During normal discharge operations on the Aratere, one of the shunt team is positioned at the head of the rake in order to give verbal instructions to the RCO to aid the coupling process. Should there be any difficulty with the coupling, the coupler can be aligned from a safe position on the deck of the runner wagon. Immediately prior to this accident, the RCO disembarked from the safe position on the runner wagon to attempt to align the coupler of the head wagon manually. In doing so they placed themselves within the danger zone (see Figure 11).

- In this case, the impediment to what is typically a straightforward process was caused by the degree of curvature of the track where the wagons were positioned. While the amount of sideways movement possible on the coupler on the EUF-class runner wagon is greater than that on standard wagons, it was still difficult to align it with the open knuckle of the coupler on the head wagon.

- The shunting team with the RCO at the head of the runner wagon conducted several coupling manoeuvres without success. At this point the RCO elected to move between the wagons to adjust the head wagon’s coupler manually.

- Moving into the danger zone to align the couplers manually was not in contravention of KiwiRail’s operating procedures when it was an operational necessity. It was likely that the RCO responded in a more automated, unconscious manner to rectify the situation after several unsuccessful attempts to couple the rake.

- Once the RCO had manually adjusted the coupler, they attempted the next coupling manoeuvre while still within the danger zone. By this seventh attempt to couple, it is likely that the RCO had become fixated on the task at hand and experienced a lapse in concentration during which they did not reposition themselves clear of the danger zone before attempting to couple the wagons again.

- The KiwiRail operating procedures warned shunting staff: “When connecting vehicles [wagons or locomotives] equipped with automatic couplers don’t stand between the vehicles, or the locomotive and vehicle while they come together. There is insufficient clearance and you may be crushed.”

- The RCO was positioned on the inside of the curve between the wagons when bringing the locomotive and runner wagon onto the rake. The couplers were still misaligned, and as a result the couplers glanced off each other when the locomotive moved. This caused the runner wagon to move towards the head wagon unexpectedly. The RCO, standing between the runner wagon and the head wagon, was struck with sufficient force that their leg moved rapidly forward and connected with the footstep of the head wagon positioned at shin height, and this resulted in an injury to the leg.

- Had the RCO vacated the danger zone before commanding a coupling movement towards their position, it is virtually certain that this accident would not have occurred.

Coupling limitations

Safety issue: The number of wagons loaded on the Aratere’s outer tracks at the time of the accident exceeded the limits that could be safely accommodated without presenting difficulty when coupling.

- There is a commercial benefit in optimising the number of wagons that can be accommodated safely on a rail deck. However, a combination of the design of the automatic knuckle couplers fitted to the wagons and the curvature on the outer tracks on the Aratere limited the carrying capacity on the outer tracks.

- The original rake length limit on the Aratere’s outer starboard track was 143 metres. In 2012, when the automatic knuckle couplers were introduced to new and existing wagons in the fleet, the Wellington ferry shunt started to experience coupling difficulties, especially on the starboard outer track of the Aratere. With about 47 minutes allowed for discharging and loading the four rakes of wagons, the difficulties associated with coupling runner wagons to head wagons caused delays that affected the sailing schedules.

- As an interim measure, the length of the rake carried on the outer tracks of the Aratere was reduced to 115 metres while a mechanical solution was worked on to overcome the coupling problem.

- To resolve the coupling issue, KiwiRail modified the existing EUF-class runner wagon with a greater coupler swing, so that the coupler could move further to the left or right if required to facilitate coupling at an angle. The EUF-class runner wagon was trialled for a month on the Aratere in late 2015. There were no issues reported when coupling to the head wagon during the trials. Following the trial, KiwiRail issued a Semi-Permanent Bulletin (a document used by KiwiRail to disseminate instructions that will apply until they are cancelled or made permanent rules), authorising the rake length limits to be extended from 115 metres to 143 metres.

- The Rail Operating Code, Section 1 was amended on 20 November 2017 to extend the maximum carrying capacity on the outer starboard track on the Aratere when sailing from Picton to Wellington to 143 metres from 115 metres.

- Despite the improvements in the runner wagon coupler, the issue was not fully resolved. The problem of coupling to the outer rakes was recorded again in March 2020.

Coupling on curves

- After the accident, KiwiRail conducted an internal investigation of the coupling issue on the Aratere. The investigation assessed, among other things, the theoretical alignment angles of the EUF-class runner wagon coupler and the head wagon coupler at different rake lengths on the outer track.

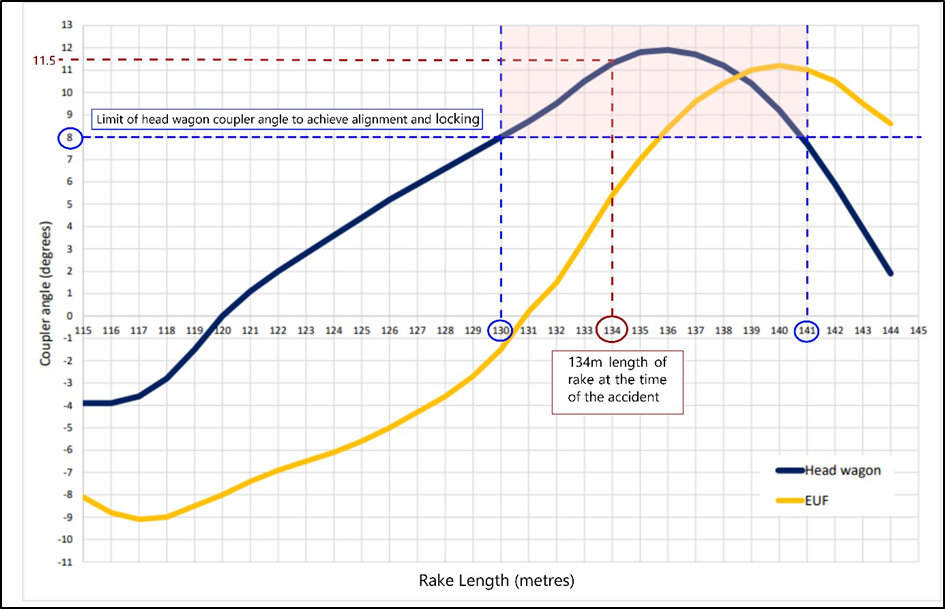

- The coupler angles are shown in Figure 12. Of interest is the blue line, which is the angle at which the coupler on the head wagon would have needed to be moved (to the nearest degree) to achieve alignment and locking at various rake lengths.

- The limit of the coupler angle on the head wagon (see Figure 12) to achieve alignment and locking is about 8 degrees. When rake lengths are between 130 and 141 metres, the head wagon requires a coupler angle greater than 8 degrees to achieve alignment and locking. This region of the head wagon coupler angle curve (highlighted red in figure 12) is the most difficult section of the starboard track on which to achieve coupler alignment and therefore coupling of wagons.

- With a rake of 134 metres (the length of rake on the starboard outer track at the time of the accident), the head wagon is within the range where coupling is most difficult. The coupler of the head wagon is required to be moved 11 degrees to couple to the runner wagon (see Figure 13). The 11-degree angle movement required is well past the ‘free’ movement of the head wagon coupler, and even if coupling is achieved there may not be sufficient capacity for the pneumatic system on the runner wagon to shift the head wagon coupler into a good enough alignment to allow the couplers to lock. (Refer Appendix 1 for the runner wagon operating quick guide).

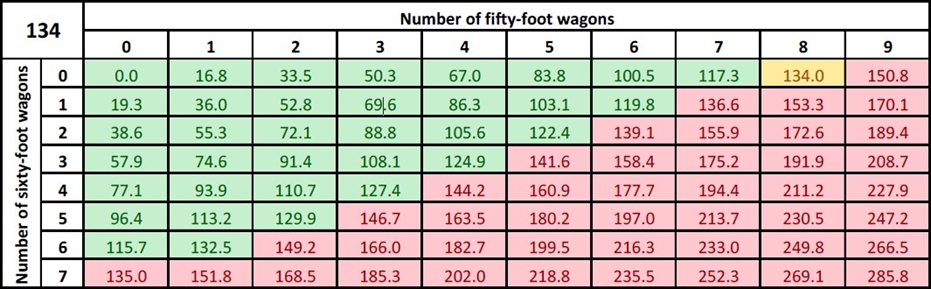

- The length of the rake on the starboard outer track was 134 metres when the accident happened. Figure 14 shows that at 134 metres the physical carrying capacity would have been equivalent to eight 50-foot (15-metre) wagons.

- It is very likely that the length of the rake on the outer starboard track and the limitation of the coupler movement on the head wagon significantly increased the difficulty for the shunt team to achieve the alignment and coupling of the wagons.

- Since this accident KiwiRail has reduced rake lengths to a maximum of 123 metres, which has improved the alignment of the couplers and reduced the risk to operational staff.

- The Commission was also advised by KiwiRail that the alignment of couplers will not be a safety issue on board the rail ferries to be introduced in 2025, due to the improved track design on board the new ships.

- The Commission has not made a recommendation due to the safety actions taken by KiwiRail to address the safety issue.

Findings Ngā kitenge

- The automatic knuckle couplers fitted to most of the KiwiRail wagon fleet are not designed to couple on tight curves.

- The difficulties experienced by the remote-control operator when attempting to align the couplers likely led to their becoming fixated on the task. This likely resulted in a lapse in concentration, whereby the remote-control operator moved the runner wagon prior to repositioning themselves clear of the danger zone.

- Had the remote-control operator vacated the danger zone before moving the runner wagon towards their position, it is virtually certain this incident would not have occurred.

- The length of the outer starboard rake was 134 metres, and this resulted in the head wagon being positioned at one of the most difficult locations for the remote-control operator to have attempted to couple it to the runner wagon.

- It is very likely that the length of the rake on the outer starboard track, and the limitation of the coupler movement on the head wagon, significantly increased the difficulty for the shunt team in achieving coupler alignment and therefore coupling to wagons.

Safety issues and remedial action Ngā take haumanu me ngā mahi whakatika

General

- Safety issues are an output from the Commission’s analysis. They typically describe a system problem that has the potential to adversely affect future operations on a wide scale.

- Safety issues may be addressed by safety actions taken by a participant, otherwise the Commission may issue a recommendation to address the issue.

- One safety issue is identified in this report.

The number of wagons loaded on the Aratere’s outer tracks at the time of the accident exceeded the limits that would have put them in a position to be safely accommodated without presenting difficulty when coupling.

- The operator (KiwiRail) has taken the following safety action to address this issue.

- On 8 July 2021 KiwiRail promulgated Semi-Permanent Bulletin No. 525. This bulletin reduced the maximum rail-lane metres on the outer tracks of the Aratere to 115 metres.

- Following this accident, KiwiRail carried out an investigation of coupling-on issues on the Aratere. The investigation determined the theoretical alignment of the EUF-class runner wagon coupler with the head wagon at various locations on the curved outer track of the Aratere. These calculations were based on rakes ranging from 115 metres to 144 metres long, in order to determine the best scenario from a coupling perspective.

- On 24 September 2021 KiwiRail approved a risk assessment based on its engineering report FT31510-4, to extend the maximum rail metres on the outer tracks on the Aratere from 115 metres to 123 metres.

- On 1 October 2021 Semi-Permanent Bulletin No. 525 was cancelled and replaced with Semi-Permanent Bulletin No. 752. This bulletin extended the maximum rail lane metres on the outer tracks of the Aratere to 123 metres.

- The Commission welcomes the safety actions taken since the accident. In this case no new recommendation has been issued.

Recommendations Ngā tūtohutanga

General

- The Commission issues recommendations to address safety issues found in its investigations. Recommendations may be addressed to organisations or people, and can relate to safety issues found within an organisation or within the wider transport system that have the potential to contribute to future transport accidents and incidents.

- In the interests of transport safety, it is important that recommendations are implemented without delay to help prevent similar accidents or incidents occurring in the future.

New recommendations

- No new recommendations were issued.

Key lessons Ngā akoranga matua

- Shunting rail vehicles is a safety-critical task. Safety-critical tasks should be designed in such a way so as not to cause additional or unnecessary risks for employees.

- Experiencing difficulties with a procedure can lead to task fixation. This can create an environment conducive to risk-taking activity and error-producing conditions.

Data summary Whakarāpopoto raraunga

Details

Conduct of the inquiry He tikanga rapunga

- On 10 April 2021, the rail regulator Waka Kotahi NZ Transport Agency notified the Commission of the occurrence. The Commission subsequently opened an inquiry under section 13(1) of the Transport Accident Investigation Commission Act 1990 and appointed an investigator in charge.

- On the same day, three investigators deployed to the site and boarded the Aratere to conduct a site examination.

- The Commission investigators secured closed-circuit television footage recorded on board the Aratere at the time of the accident and the Tranzlog download data from KiwiRail, and obtained records of training, shift rosters, certification and other relevant documentation.

- The Commission investigators conducted interviews with the rail operator and the RCO.

- A meeting between the Commission investigators and KiwiRail managers was held on 19 October 2021 regarding this accident.

- The Commission obtained further documentary evidence from KiwiRail and Interislander pertaining to the loading and discharging operations on board the Aratere.

- On 22 June 2022 the Commission approved a draft report for circulation to three interested persons for their comment.

- The Commission received three submissions, and any changes as a result of these submissions have been included in the final report.

- On 24 August 2022, the Commission approved the final report for publication.

Glossary Kuputaka

- Couple

- Connect rail vehicles together

- Head wagon

- The first wagon at the locomotive end of the rake.

- KiwiRail

- KiwiRail Limited

- Port

- The side of a vessel that is left when facing forward

- Rake

- A group of vehicles, usually not formed as a train, moved as a unit during shunting and marshalling.

- Runner wagon

- A specialised wagon, classified as EUF class, that is attached to a shunt locomotive to aid the loading and discharge process.

- Semi-Permanent Bulletin

- A document used by KiwiRail to disseminate instructions that will apply until they are cancelled or made permanent rules

- Shunt

- A generic term for the movement of locomotives, wagons and carriages using a purpose-built railway engine (shunt)

- Starboard

- The right side of a vessel when the viewer is facing forward

- Terminal

- Wharf, buildings and marshalling area

- Wagon

- A wagon is a rail vehicle that moves freight on the rail network.

Appendix 1. EUF Ferry Shunt Wagon Operating Quick Guide