Railway track workers were at risk when a train approached in what they thought was a protected work area. Administrative procedures like forms and radio calls are not enough to mitigate this sort of risk. Everyone involved in workplace safety needs to communicate clearly. TAIC recommends KiwiRail improve engineering failsafes to mitigate risk of human error.

Executive summary Tuhinga whakarāpopoto

What happened

- At 0747 on 21 September 2020, a freight train on the East Coast Main Trunk line entered a section of track that the rail protection officer believed was part of a protected work area and which was already occupied by a contractor operating a hi-rail vehicle.

- The hi-rail vehicle was working under the protection of a rail protection officer who was responsible for organising the safety of the work area.

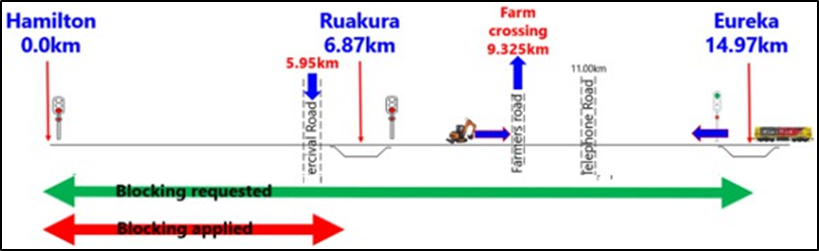

- It was intended that the protected work area extend for a distance of about 15 kilometres between Hamilton and Eureka. However, due to a number of miscommunications, Train Control only protected the track between Hamilton and Ruakura for a distance of about 7 kilometres.

- It resulted in the hi-rail vehicle operator unknowingly working on the track in a section that had not been protected from rail traffic.

- A collision between the train and the hi-rail vehicle was only avoided because the hi-rail vehicle had voluntarily cleared the track about five minutes earlier.

Why it happened

- While establishing the protected work area, neither the rail protection officer nor the train controller noticed a discrepancy recording the limits of the protected area that they were referencing.

- The rail protection officer was unfamiliar with the area of operation.

- The ineffective use of communication skills with erroneous read-backs (hear-back error) while trying to implement an administrative control measure resulted in a designated procedure not being followed correctly and protection arrangements not being put into place.

What we can learn

- The key lessons arising from this inquiry are:

- Workers on the national rail network are at risk of serious harm if a rail vehicle enters the section of track while they are working.

- All personnel involved in safety-critical operations should recognise non-technical, and particularly communication, skills as an important risk mitigation measure.

- The use of engineering control measures may enhance the safety of track workers.

Who may benefit?

- Rail operators (including train controllers), rail protection officers and track maintenance personnel may benefit from the findings in this report.

Factual information Pārongo pono

Background

- A hi-rail vehicle (HRV) operator was scheduled to carry out ballast profiling work between Ruakura and Hemopo on the East Coast Main Trunk (ECMT) line between 21 and 24 September 2020 inclusive. The work was to be carried out between 0700 and 1700 daily under the protection of a rail protection officer (RPO).

- Due to a planned network maintenance shutdown, there was only one train scheduled to pass through the area during the Monday shutdown period, which was on the morning of 21 September.

Narrative

- On Sunday 20 September 2020, the RPO travelled to Hamilton in preparation for work on the ECMT. That evening the RPO checked the local Signalling & Interlocking Diagrams (diagrams indicating the location of signals and motor points), and the related paperwork (documentation that includes the Daily Information Bulletin and Signalling & Interlocking Diagrams), in preparation for commencing work the next day.

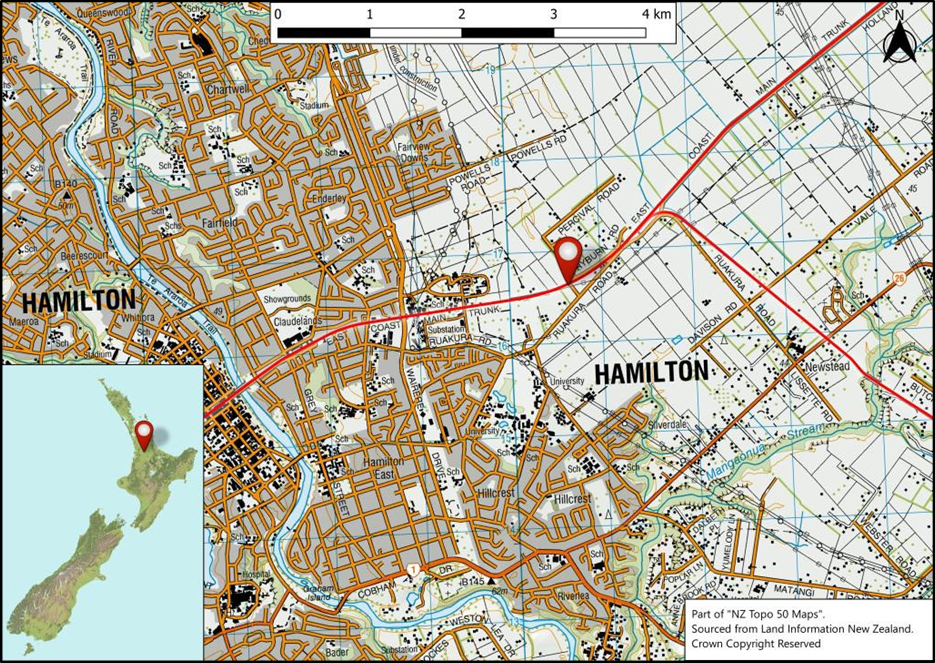

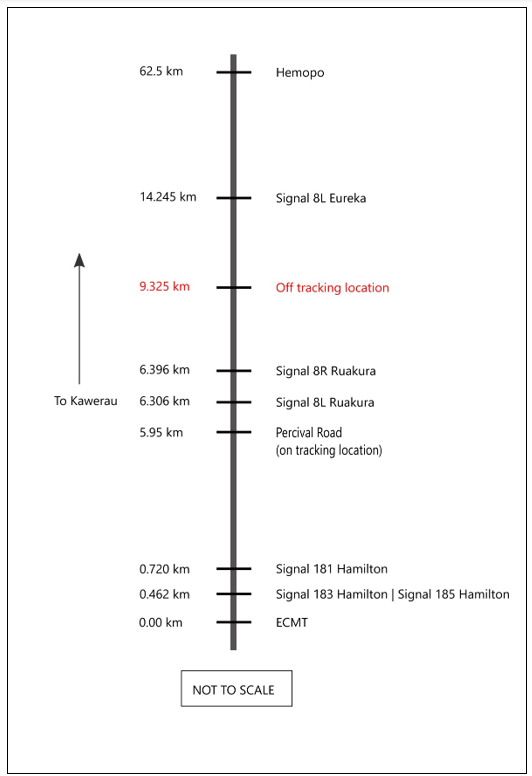

- At about 0630 on Monday 21 September 2020, the HRV operator arrived at Percival Road (see Figure 2) and unloaded the vehicle.

- At about 0700 the RPO arrived at Percival Road and conducted a pre-start meeting with the HRV operator. It included the information contained on the Daily Information Bulletin (the Daily Information Bulletin was issued by KiwiRail and applied for on the day of the operation only, and included information on general daily instructions, running of extra trains and maintenance work) and was followed with a safety briefing.

- At 0705 the RPO contacted Train Control (TC) using the radio fitted inside the KiwiRail vehicle. Protection in the form of signal blocking was requested, which allowed the HRV operator to work on the track between Hamilton and Eureka (see Figure 2).

- The RPO was using a track occupancy cross check sheet known as an Mis (Miscellaneous) 71. The RPO had already part-completed the form and described the work area as ‘work between Hamilton and Eureka’.

- Track occupancy protection was in place by 0706, the RPO and HRV operator locked onto (before leaving the safe place, all personnel on-site must attach a padlock for themselves and a padlock for any vehicle under their control that will foul the track to the lock-on frame) the RPO’s frame (the lock-on frame showing people and vehicles within the worksite at any given time), and the vehicle on-tracked. The vehicle made its way towards Eureka, carrying out ballast work at pre-designated places (see Figure 2).

- When the vehicle was safely on track, the RPO drove his road vehicle to the agreed off-tracking point, located about 3 kilometres (km) to the east (see Figure 2).

- At about 0745 the RPO contacted the HRV operator to inform them that the blocking protection expired at 0800, as per the clearance provided by TC to allow the passing of the train.

- After they received the call, the HRV operator made their way to the agreed off-tracking safe place.

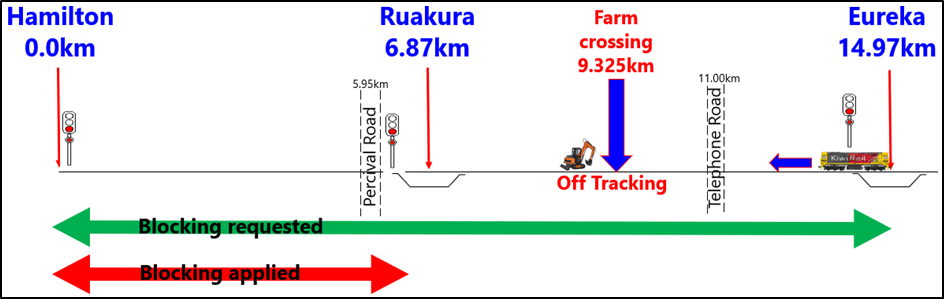

- At about 0747 a train entered the Eureka to Ruakura section while it was still occupied by the HRV operator. The train and the vehicle were separated by a distance of about 5 km (see Figure 3).

- At about 0750 the HRV was safely removed from the track.

- Both the RPO and the HRV operator remained at the designated safe location, clear of the track.

- At about 0755 both the HRV operator and RPO noticed the headlights of a train approaching from the direction of Eureka. The RPO immediately contacted TC to advise them a train was operating in their protected work area (PWA).

- The train passed the designated safe location about 5 minutes after the vehicle had off-tracked.

- There was no collision and the train continued to Hamilton without further incident.

- The train controller reported that there had been a potential safe-working incident to the Network Control Manager and an investigation was initiated.

Personnel information

- At the time of the incident, the RPO had 14 years’ experience in this role, initially as an HRV operator and then for the last few years with KiwiRail. He held current certification for his role. The RPO underwent a post-incident drug and alcohol test that returned a negative (clear) result.

- The HRV operator worked for a subcontractor to KiwiRail and had 25 years’ rail experience, the last 14 years operating an HRV for their current employer.

- The train controller completed training at the TC school in December 2015. They were certified on the Auckland Zone desk in July 2016 and then on the ECMT desk in March 2020. The train controller underwent a post-incident drugs and alcohol test that returned a negative (clear) result.

Meteorological information

- On the day of the incident the weather was fine with clear visibility.

Recorded data

- The locomotive was fitted with a data recording system known as Tranzlog. The data was obtained by the Commission.

Train/Vehicle information

- The train involved in the incident was a DC class locomotive travelling without any wagons attached.

- The Commission found no evidence that either the condition or the operation of the train contributed to the incident.

Previous occurrences

-

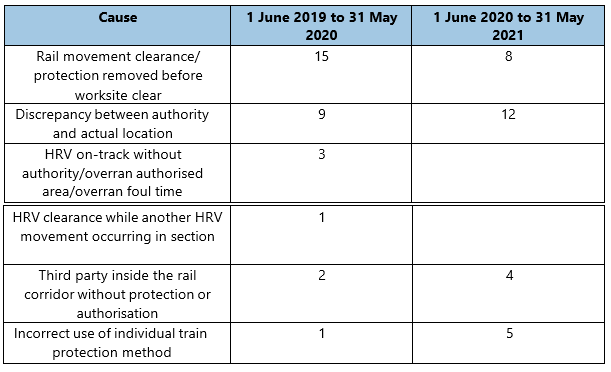

The Commission has received statistical data from KiwiRail about track occupancy irregularities where miscommunication was identified as a contributing factor.

Table 1 shows that from 1 June 2019 until 31 May 2021, KiwiRail recorded 61 track occupancy irregularities. Twenty-one of the irregularities were due to a discrepancy between the authority and the actual location, whereby miscommunication was considered to be a contributing factor to the incident.

Analysis Tātaritanga

Introduction

- The following section analyses the circumstances surrounding the event to identify those factors that increased the likelihood of it occurring or the severity of its outcome. It also examines any safety issues that have the potential to adversely affect future rail operations.

- The safe separation and protection of track workers from rail vehicles is a fundamental premise for rail operations. It is therefore essential that proven safe methods of working are in place to prevent the potential for interactions between rail traffic and track workers.

- The KiwiRail Track Safety Rules have 10 track protection systems that are available for use, depending on a combination of: the nature and duration of the work activity; the signalling system on the section of track; and the number of trains passing over this section during an 8 hour working day.

- KiwiRail Operating Rule 908 – Blocking is used to protect a track occupation within automatic signalling areas by TC holding signals that govern entry into the PWA at red (STOP).

- In this incident, the RPO and the train controller did not share a common understanding of the limits of the PWA. As a result, an HRV cleared the track outside the PWA only a few minutes before a locomotive passed through travelling at close to the maximum authorised line speed.

- During the incident analysis, fatigue was ruled out as having contributed to this incident, as both the train controller and the RPO were well rested.

- The signalling system data indicated that the signals were functioning as designed at the time of the incident.

- The results of post-incident toxicological tests performed on the KiwiRail staff involved in the incident were negative for alcohol and other impairing drugs.

KiwiRail Operating Rule 908 – Blocking

- Rule 908 required that the person proposing to occupy or obstruct a section of track protected by interlocked signalling (the addressee) was to personally advise TC of their:

- identity

- type of protection requested

- on-tracking location (at location)

- occupation area, including off-tracking location

- time required for the work

- nature of the work.

- Before authorising the track occupation, the train controller was required to:

- carry out pre-authorisation checks to ensure the proposed occupancy did not conflict with other rail movements, either train or HRV

- verify the position of the last train to clear the on-tracking location

- record the details of the track occupation on the TC diagram

- apply blocking of signals to prevent trains from entering the occupied area before authorising the track occupation.

- The train controller would then authorise the track occupation by stating the:

- addressee

- commencement time

- clearance time

- ‘At’ location

- authority to either proceed from (or to), or work between (locations)

- last train clear time of the on-tracking ‘At’ location

- section of track verified as blocked.

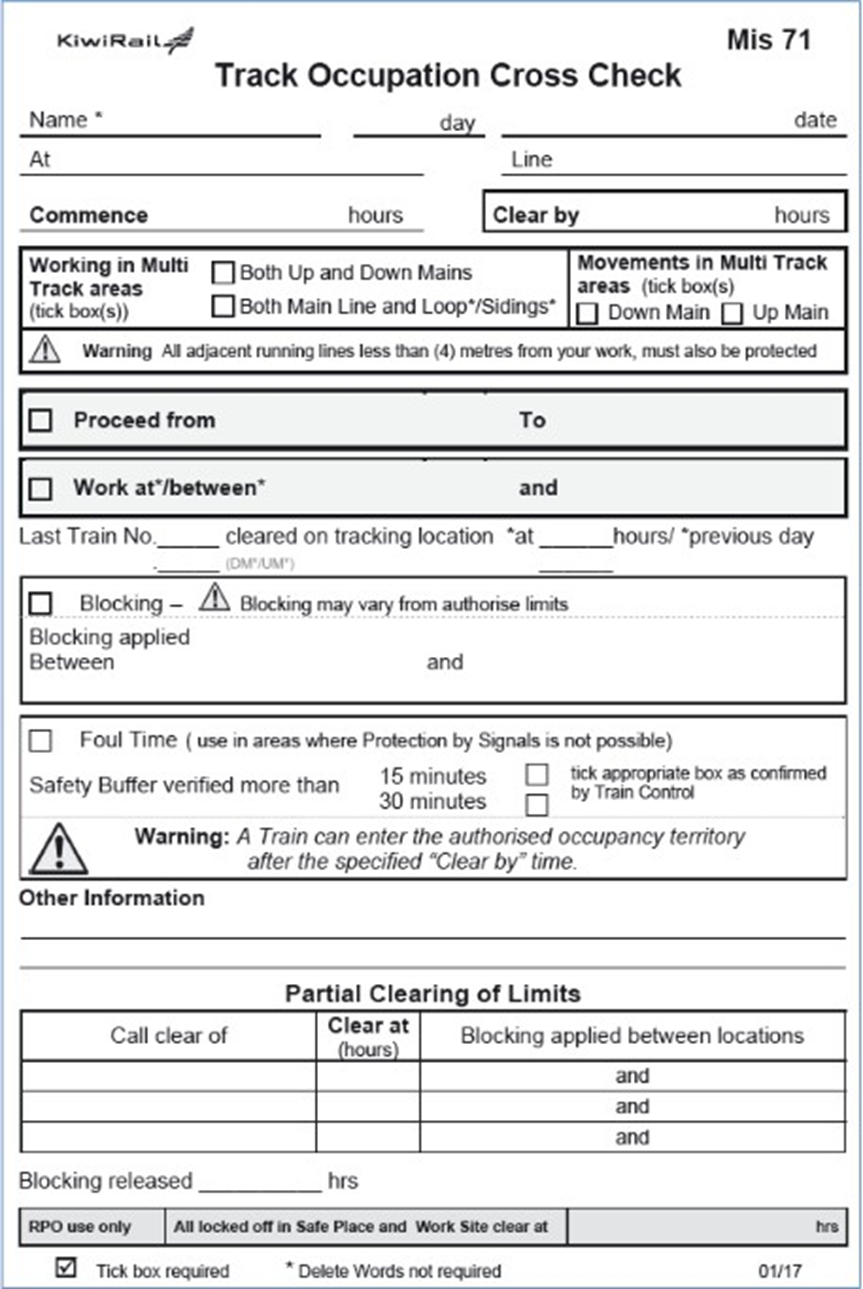

- The addressee obtaining the blocking would then complete an Mis 71 Track Occupation Cross Check form (see Appendix 1), with the instructions issued by TC, including the:

- addressee

- commencement time

- clearance time

- ‘At’ location

- authority to either proceed from (or to), or work between (locations)

- last train clear time of the on-tracking ‘At Location’

- section of track verified as blocked.

- The next check is for the addressee to read back the instructions recorded on the Mis 71 to the train controller, who then verifies or corrects the instructions before the addressee can occupy the PWA.

- Features and locations referred to in the communication between the RPO and the train controller are shown in Figure 4.

-

All communication with TC is recorded. A download of the radio communication between the RPO and the train controller showed that at 0705 the RPO made an enquiry to TC by radio. A transcript of that communication can be seen below:

“Good morning control, 70367 [call sign for the RPO] down here requesting blocking thanks mate. Currently at the five decimal nine five kilometre between Te Rapa and Ruakura wanting to work between Te Rapa 181 Signal and Eureka 8L after the next service thank you.”

-

After carrying out a pre-authorisation check, the train controller responded:

”Yeah, Roger that 70367, show you on-tracking at the five decimal nine five kilometre mark that is between Ruakura and Hamilton. Show you working between the 181 Signal Hamilton through to 8L Signal Ruakura.

Commencement time of 0706, give you through to 0800.

Last train to clear the limits was M52. Clearing the limits at 0551.

Blocking in place from Signals 185, 183 Hamilton through to 8R Signal at Ruakura, over.”

-

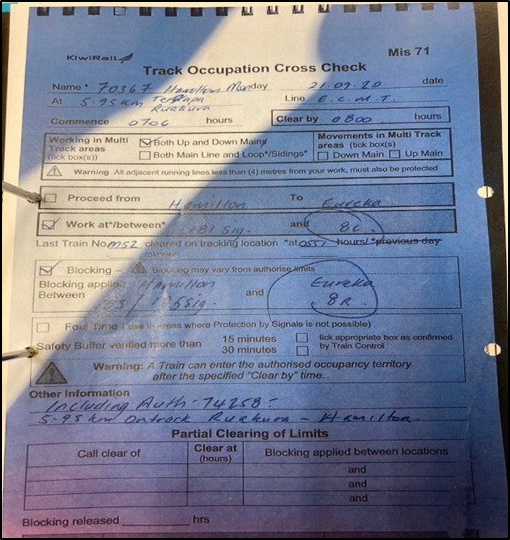

The RPO accepted the blocking and completed the Mis 71 Track Occupation Cross Check form (see Figure 5) and read back the instructions to TC at 0706, stating:

“Roger, thank you control, 70367 currently at 5.95 kilometre between Hamilton and Ruakura, commencing 0706 hours clear by 0800.

Wanting to work between Hamilton 181 Signal and Eureka 8L

Last train M52 cleared location at 0551.

Blocking has been applied Hamilton 185 Signal 183 and Ruakura 8R Signal.

Also authority for 74258.”

-

After listening to the readback, the train controller stated:

“Yes, Roger that is all correct. Yes, that also covers 74258.”

-

The RPO closed the radio communication stating:

“Roger, thank you control, 70367 out.”

Rule 908 – Blocking should have provided adequate safe-working controls. Although the process for the signal blocking was followed, the RPO and the train controller did not listen to each other sufficiently to prevent them having a different understanding of the limits of the PWA.

Protection of the worksite

- When the RPO asked for an authority to work between Te Rapa 181 Signal and Eureka 8L Signal, the train controller gave authority to work between Hamilton 181 Signal and Ruakura 8L Signal. Blocking had been applied to Hamilton 183 and 185 Signals and Ruakura 8R Signal. The RPO’s read-back stated that work between Te Rapa 181 Signal and Eureka 8L Signal and blocking applied to Signals 183 and 185 Te Rapa and Ruakura 8R.

- The train controller verified the RPO’s read-back as being correct, despite the RPO stating a work between limit as Eureka 8L Signal and not Ruakura 8L as authorised and as drawn on the TC diagram. The opportunity to correct the RPO’s understanding of the limits of the track occupation was therefore lost.

- It was likely that the RPO’s unfamiliarity of the local area contributed to the misunderstanding. During the interview, the RPO stated that he had partially filled the Mis 71 Track Occupation Cross Check form before arriving on-site. The Mis 71 showed the ‘work between limit’ as Eureka 8L Signal and blocking applied at Eureka 8R Signal. These limits were in conflict with the work between limit at Ruakura 8L and blocking at Ruakura 8R Signal authorised by the train controller.

- Once the RPO had possession of the track occupation authority, valid until 0800, both the RPO and the HRV operator discussed the working limits and agreed that the recommended off-tracking location would be at a farmer’s private access track at about the 9.35 km mark. The agreed off-tracking location was about 3 km outside the limit of the PWA, thereby potentially putting the HRV into the path of the next train travelling towards Te Rapa, Hamilton.

- Witness statements confirmed the HRV voluntarily cleared the track at about 0750, 10 minutes before the authorised ‘clear by’ time of 0800. However, at the time of clearing the track the HRV was 3 km outside the limits of the PWA.

- The train was travelling at 60 kilometres per hour. Had the HRV remained on-track until 0800, the time agreed between the train controller and RPO on the Mis 71 Track Occupation Cross Check form, it would likely have been struck by the train at about 0752.

Mis 71

-

The Mis 71 is a Track Occupation Cross Check form which is completed as part of the procedure for requesting blocking.

TC is the authority for authorising track occupation. Whoever is requesting track occupation is required to complete an Mis 71. Along with other information, the form should contain the instructions issued by the train controller at the time of request (see Appendix 1).

- At the time of this incident there was an instruction in place preventing the RPO completing the form before making the request. On 12 February 2020, about seven months prior to the incident, KiwiRail had promulgated Semi-Permanent Bulletin No. 124 (see Appendix 2), which stated that the only information that could be pre-completed on all Operating and Authority documents (which included Mis 71s) was the addressee, location and date.

- Had the RPO completed the Mis 71 form during the process of requesting track occupation with the train controller, instead of pre-completing earlier that morning, it is likely that the discrepancy may have been identified and the error rectified.

Non-technical skills

Safety issue – Implementation of an administrative control measure designed to provide protection for a track worker was unsuccessful due to the poor use of non-technical skills.

- Non-technical skills can be defined as the cognitive, social and personal resource skills that complement technical skills and contribute to safe and effective task performance. Sub-categories of non-technical skills include situational awareness, conscientiousness, communication, decision-making and action, teamwork, workload management and self-management.

- The train controller and the RPO had both undergone training in non-technical skills. Nevertheless, human error will occur, and this incident highlights the importance of using effective communication strategies to guard against such occurrences. The likelihood of erroneous read-backs (hear-back error) is increased when those communicating have a preconceived notion of what they are expecting to hear. While expectation bias cannot necessarily be eliminated, defences (such as specific phraseology and challenge-respond techniques) go some way to ensuring a complete and correct understanding is shared by both parties.

- Good communication is a key function of safety within the rail industry. There were several examples in this incident where the use of good communication skills would have helped to establish a common mental model of the blocking protection that was being requested. Had instructions been repeated back clearly, and their accuracy challenged, a serious error could have potentially been identified and very likely rectified.

- On this occasion Rule 908 – Blocking was the required procedure to achieve a PWA. However, the process was unsuccessful because of the poor use of non-technical skills between participants which did not detect the error and provide an opportunity to rectify it.

Rail protection officer

- ‘Rail protection officer’ is a generic term given to the person responsible for protecting individuals or multiple worksites, depending on the level of competency held. That person has overall responsibility for communicating with TC and coordinating the movement of trains and HRVs through and within the work area.

- On this occasion the RPO was providing protection for the operator of a HRV in an area he was unfamiliar with and which, under the Rule 908 – Blocking process, was likely to be the reason he did not question the train controller’s read-back of the meterage and locations they intended to block.

-

Operators of HRVs are required by KiwiRail to be location certified. KiwiRail’s Track Safety Rule 116 (b) states in part:

Driver without local knowledge: “Where for some reason the driver is not a person with adequate local knowledge, the driver must be accompanied by a second person with such knowledge, who holds the appropriate licence to operate.”

- Although the cause of this incident may have been rectified by the use of good non-technical skills, the RPO’s lack of familiarity with the area was a limitation. Currently, local knowledge is not a requirement for RPOs, but given their overall responsibility for providing rail protection within a PWA, a good understanding and knowledge of the local area may well influence their decision-making and actions. It is a constraint that should be considered by rail operators when planning similar operations in the future.

Engineering control measures

Safety issue – The use of an administrative control measure was not effective on its own, and the adoption of engineering control measures when establishing PWAs would provide an enhanced level of protection for track workers.

- From 1 June 2019 until 31 May 2021, KiwiRail recorded 61 track occupancy irregularities. Twenty-one of the irregularities were due to a discrepancy between the authority and the location on-site and poor communication was considered to be a contributing factor (track occupancy statistics provide by KiwiRail at the request of the Commission).

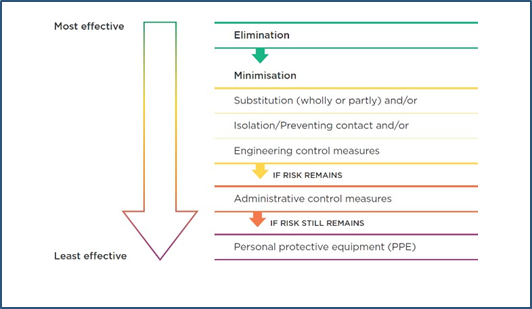

- The Health and Safety at Work (General Risk and Workplace Management) Regulations 2016 require a Person Conducting a Business or Undertaking to identify hazards and protect against them using a hierarchy of control measures (see Figure 6), to maintain and review the control measures, and to provide information, supervision, training and instruction to workers.

- Figure 6 explains the effectiveness of the various safety control measures that may be used to help reduce the risk to workers. In this incident, the primary safety control was an administrative control and relied upon those involved following Rule 908 – Blocking completing the correct paperwork, communicating effectively and identifying the correct signals to isolate. If the process is administrated correctly then blocking control is successfully achieved.

- However, as can be seen from the number of track occupancy irregularities, 21 were due to a discrepancy between the authority and the location on-site. In the hierarchy of safety controls, it is evident that administrative controls are the least effective and can fail to provide the protection that track workers (working in the rail corridor and faced with the danger of trains moving through their worksite) require.

- On this occasion there were no fatalities or injuries, but the incident provides an opportunity to learn important safety lessons and try to prevent a future reoccurrence. Administrative controls can be effective when implemented correctly. However, given the serious consequences of an accident occurring in the rail corridor, more effective engineering controls should ideally be the preferred option to reduce the frequency of similar accidents occurring in the future.

- The Commission has made a recommendation to the Chief Executive of KiwiRail to provide an enhanced level of protection for track workers by adopting the use of engineering control measures when establishing PWAs.

Findings Ngā kitenga

- A train entered an area of track that was intended to be blocked for work by a hi-rail vehicle.

- The hi-rail vehicle was off and clear of the track before the train passed through the area.

- The rail protection officer was unfamiliar with the area of operation.

- The rail protection officer and the train controller had a different understanding of where the blocking was required. As a result, both parties had different mental models of the area that was being protected and the Protection Work Area limits.

- The rail protection officer had partially completed the Mis 71 form before commencing the blocking procedure with Train Control.

- Had the rail protection officer completed the Mis 71 form during the process of requesting track occupation with the train controller it is likely that the discrepancy may have been identified.

- The use of poor non-technical skills between the rail protection officer and Train Control resulted in procedural errors being made that went undetected.

- There was no engineering control measure available to mitigate the risk of human error while carrying out an administrative procedure.

- The train was travelling at 60 kilometres per hour. Had the hi-rail vehicle remained on track until 0800, the time agreed between the train controller and the rail protection officer, it would likely have been struck by the train

Safety issues and remedial action Ngā take haumanu me ngā mahi whakatika

General

- Safety issues are an output from the Commission’s analysis. This output typically describes a system problem that has the potential to adversely affect future operations on a wide scale.

-

Safety issues may be addressed by safety actions taken by a participant, otherwise the Commission may issue a recommendation to address them.

Two new safety issues were identified in this report.

The use of an administrative control measure was not effective on its own, and the adoption of engineering control measures when establishing PWAs would provide an enhanced level of protection for track workers.

- The use of administrative control measures is widely used throughout the rail industry. However, records show that the safety of track workers is sometimes inadequate because of the ineffective implementation of this type of control measure.

- The Commission believes that improving the safety of track workers, and reducing the frequency of track occupancy irregularities, should be a priority for future operations and is best achieved by the implementation of more effective engineering control measures to minimise risk.

-

The Commission has made a recommendation in Section 6 of this report to address this issue.

The implementation of an administrative control measure designed to provide protection for a track worker was unsuccessful due to the poor use of non-technical skills.

- The incident highlights the importance of using proficient non-technical skills when trying to create a safe working environment, particularly for PWAs.

-

In 2012, as part of Inquiry RO 2011-101, the Commission issued a recommendation (002/12) to the Chief Executive of the NZ Transport Agency (the NZ Transport Agency has primary regulatory responsibility for rail safety in New Zealand. NZ Transport Agency is the previous name for Waka Kotahi NZ Transport Agency) that he require the Executive of the National Rail System Standards (NRSS) to develop standards to ensure all rail participants meet a consistently high level of Crew Resource Management (now Non-Technical Skills), and better communication to staff, which includes the use of standard rail phraseology.

On 31 March 2017, the NZ Transport Agency updated the Commission as follows:

It is noted that the Commission issued its most recent recommendation on non-technical skills to the NZ Transport Agency in 2012 and that this is still open. The recommendation required that the practice of non-technical skills be recognised in the NRSS. The NZ Transport Agency continues to work with KiwiRail on this issue, and in December 2016 issued a Safety Improvement Plan Notice in accordance with section 36 of the Railways Act 2005 requiring KiwiRail to prepare a Safety Improvement Plan to address the implementation of non-technical skills into its rail operations.

On 1 November 2017, the NZ Transport Agency updated the Commission as follows:

The NZ Transport Agency approved KiwiRail’s Safety Improvement Plan regarding non-technical skills in April 2017. In their most recent update on the Non–Technical Skills project, KiwiRail reported that the project is on time, within budget and meeting the project specifications. As of 13 October 2017, the NZ Transport Agency has also agreed to the integration of a stabilised approach and risk-triggered commentary driving into the scope of the Safety Improvement Plan requirements.

On 13 September 2021, KiwiRail updated the Commission as follows:

Since January 2020, 4,718 employees were enrolled into the course. To date, 4,014 have either passed the course through attending a Toolbox briefing, completed the embedded sessions within our existing programmes for new staff, or completed the eLearn within KLE (KiwiRail Learning Exchange).

Recommendations Ngā tūtohutanga

General

- The Commission issues recommendations to address safety issues found in its investigations. Recommendations may be addressed to organisations or people, and can relate to safety issues found within an organisation or within the wider transport system that have the potential to contribute to future transport accidents and incidents.

- In the interests of transport safety, it is important that recommendations are implemented without delay to help prevent similar accidents or incidents occurring in the future.

- The use of a single administrative control measure to establish a PWA was ineffective and did not provide the track worker with adequate protection.

New recommendation

-

On 8 December 2021, the Commission recommended that KiwiRail carry out an analysis of how it could best incorporate engineering control measures into both its current and future operations to minimise the risks that human factors play in effective protection for track workers. (009/21)

On 16 December 2021, KiwiRail replied:

KiwiRail agrees with the intent of this recommendation. Work is currently underway to renew the Train Control system which will give us the technology to move to a form of hand-held track worker interaction inthe future.

The strategy is to deliver a Business Case for this next year to be funded and delivered in the 2025 - 2027 funding period. We will have completed implementation of the new Train Control system by 2025.

Key lessons Ngā akoranga matua

- Workers on the national rail network are at risk of serious harm if a rail vehicle enters their section of track while they are working.

- All personnel involved in safety-critical operations should recognise non-technical, and particularly communication, skills as an important risk mitigation measure to ensure they have a collective understanding of what is required to operate safely.

- The use of engineering control measures will help to further minimise risk and may enhance the safety of track workers.

Data summary Whakarāpopoto raraunga

Details

Conduct of the inquiry He tikanga rapunga

- On 21 September 2020, the NZ Transport Agency (Waka Kotahi) notified the Commission of the occurrence. The Commission subsequently opened an inquiry under section 13(1) of the Transport Accident Investigation Commission Act 1990 and appointed an Investigator in Charge.

- The Commission interviewed the:

- RPO

- HRV operator

- train controller.

- The Commission obtained the following documents and records for analysis:

- TC communication recordings between the RPO and TC

- training records of the RPO and train controller

- TC diagram

- the Daily Information Bulletin for 21 September 2020 (R) ECMT

- signals data (CT Log) for the section of track between Hamilton and Eureka

- Tranzlog data from KiwiRail for train M52 on 21 September 2020

- TC communication recordings between M52 and TC.

- On 22 September 2021 the Commission approved a draft report for circulation to four interested persons for their comment.

- The Commission received four submissions, and changes as a result of these have been included in the final report.

- On 8 December 2021, the Commission approved the final report for publication.

Glossary Kuputaka

- Ballast ploughing

- Application of ballast to a track

- Blocking

- The process of keeping signals and/or points tagged or collared to prevent a train entering a section of track that the blocking is protecting

- Hi-rail vehicle

- A vehicle fitted with equipment that gives the capability to travel on both road and rail.

- Lock-on frame

- A metal frame device that contains numbered locations where individually assigned padlocks are attached, to signify that a padlock owner is occupying the Danger Area within a PWA. Before the RPO authorises personnel to leave the safe place, they must attach their RPO padlock to the lock-on frame handle. All personnel and visitors on site must then attach padlocks for themselves before leaving the safe place, and padlocks for any vehicles under their control that will foul the track. When clearing the track for a rail movement (train), personnel must secure vehicles under their control in a safe mode, clear of the track, before returning to the safe place and locking off. After removing their padlock, personnel must not foul the track until they are authorised to resume work by the RPO. The requirement to use the system was contained in KiwiRail’s Track Safety Rule 902(g).

- On/off track

- The location where an HRV will on-track or off-track

- Rail operator

- Provides or operates a rail vehicle, whether or not it engages rail personnel to do so, or to assist in doing so, on its behalf. It does not include those rail personnel.

- Rail Protection Officer (RPO)

- A person with overall responsibility for providing rail protection for a PWA. They advise all site protectors and operators/drivers of the details of the protection arrangements before commencing work or entering the PWA, authorise movements to enter or proceed through the PWA, co-ordinate the movement of rail vehicles in the PWA, and communicate with train control and supervise site protectors when more than one worksite is operating. The RPO’s name and contact details are shown on the Daily Information Bulletin, which details the locations and operating times of worksites around the rail network.

- Train control

- The centre from where the movement of all rail vehicles and track access in a specified area are brought under the direction of a Train Controller

Appendix 1. Mis 71 Track Occupation Cross Check form

Appendix 2. Semi-Permanent Bulletin No. 124

Related Recommendations

On 8 December 2021, the Commission recommended that KiwiRail carry out an analysis of how it could best incorporate engineering control measures into both its current and future operations to minimise the risks that human factors play in effective protection for track workers. (009/21)