In April 2016, a Guimbal Cabri helicopter had an in-flight engine fire. The pilot landed safely and escaped unhurt but the fire destroyed the helicopter. The Commission found that the fire was due to a faulty spark plug, but the way it failed is so rare that there are no significant implications for aviation safety, so there are no recommendations in this case. The CAA and the manufacturer have taken action to identify other defective spark plugs. The safety lesson is that maintenance personnel need to be vigilant for anomalies when installing components, even from approved suppliers.

Executive summary Tuhinga whakarāpopoto

- On 15 April 2016, a pilot was on a solo navigation training flight in the central North Island in a Hélicoptères Guimbal Cabri G2 helicopter. Shortly after taking off from Rotorua he heard a loud bang followed by a continuous clattering noise. Soon afterwards, smoke entered the cabin.

- The pilot landed immediately and vacated the helicopter. The pilot was not injured, but the helicopter was destroyed by fire.

- The Transport Accident Investigation Commission (the Commission) found that the in-flight fire was initiated by the ejection of a ceramic insulator and centre electrode from one of the engine spark plugs. The loss of the spark plug allowed the combustion flame from that cylinder to ignite the engine cooling shroud.

- The Commission also found that the failed spark plug was a genuine part that had been approved by the relevant airworthiness authority for use as a part of the helicopter’s ignition system, but it failed because it had not been swaged during the manufacturing process. Swaging was the process required to bend the cold metal into place to hold in the insulator.

- This type of failure with spark plugs is so rare that it does not have significant implications for aviation safety.

- The pilot’s prompt actions were appropriate and commendable. The immediate landing, combined with the protection provided by the engine bay firewall, prevented a more serious outcome.

- The Commission issued no recommendations. The safety actions taken by the Civil Aviation Authority of New Zealand and the manufacturer of the helicopter, in conjunction with the European Aviation Safety Agency, were considered sufficient to identify other defective spark plugs.

- The key lesson arising from the inquiry was that maintenance personnel need to be vigilant for product anomalies when installing components onto aircraft, even when the components come from approved suppliers.

Conduct of the inquiry He tikanga rapunga

- At 1640 on Friday 15 April 2016, the Civil Aviation Authority of New Zealand (CAA) notified the Transport Accident Investigation Commission (the Commission) of the occurrence. The Commission opened an inquiry under section 13(1)b of the Transport Accident Investigation Commission Act 1990 and appointed an investigator in charge.

- On 16 April 2016, an investigation team travelled to Rotorua. The on-site examination was commenced the same day.

- On 17 April 2016, the wreckage was removed from the accident site with the support of the New Zealand Fire Service and its hazardous materials unit (the helicopter structure was primarily carbon-reinforced fibre, which is very hazardous when burnt). The wreckage was transported to the Commission’s Wellington technical facility in a sealed container, where a more detailed examination was completed. Commission investigators also interviewed local witnesses and the pilot.

- On 18 April 2016, the investigators travelled to Tauranga to collect the aircraft maintenance records, interview maintenance staff and inspect other Hélicoptères Guimbal (Guimbal) Cabri G2 (Cabri) helicopters. The pilot’s instructor was interviewed later the same day in Taupo.

- On 22 April 2016, the Bureau d’Enquêtes et d’Analyses (BEA) of France appointed an Accredited Representative to the inquiry in accordance with the provisions of Annex 13 to the Convention on International Civil Aviation (France, as the state of manufacture of the helicopter, was entitled to participate in the investigation). The Accredited Representative appointed a specialist from Guimbal as a technical advisor.

- On 30 May 2016, at the request of the Commission, the Japan Transport Safety Board, as the representative of the state of manufacture of the spark plug, appointed one of its investigators to assist with technical enquiries related to the investigation.

- On 1 August 2016, the Commission advised the CAA of concerns regarding the DENSO Corporation of Japan (DENSO) W24EMR-C spark plug installed on the engine. On 10 August 2016, the CAA issued a Continuing Airworthiness Notice regarding that model of spark plug (CAA Continuing Airworthiness Notice – 74-002, DENSO W24EMR-C Spark Plugs – Inspection, issued 10 August 2016). On 30 September 2016, the European Aviation Safety Agency (EASA), the airworthiness authority for the Cabri helicopter, issued a Service Information Bulletin recommending that all operators of Cabri helicopters inspect DENSO W24EMR-C spark plugs for serviceability (EASA Safety Information Bulletin Airworthiness, SIB No: 2016-15, issued 30 September 2016).

- On 6 October 2016, two Commission investigators travelled to Rotorua to supervise a series of tests conducted by the New Zealand Lycoming field representative. The tests used the same type of engine and the same model of spark plug that had been installed on the accident helicopter.

- On 11 and 12 January 2017, two representatives of DENSO Japan, the manufacturer of the spark plug, visited the Commission. They inspected the wreckage and examined the spark plugs removed from the engine, and gave a presentation on the production process for the subject spark plugs.

- On 23 March 2017, Quest Integrity NZL Limited completed a metallurgical examination and failure assessment of the DENSO spark plugs installed on the engine. Guimbal and DENSO were invited to comment on the metallurgy report prepared by Quest.

- On 28 July 2017, the Commission approved a draft report for circulation to interested persons for comment. The Commission has considered the submissions received and any changes as a result of those submissions have been included in this report.

- On 27 September 2017, the Commission approved the report for publication.

Factual information Pārongo pono

History of the flight

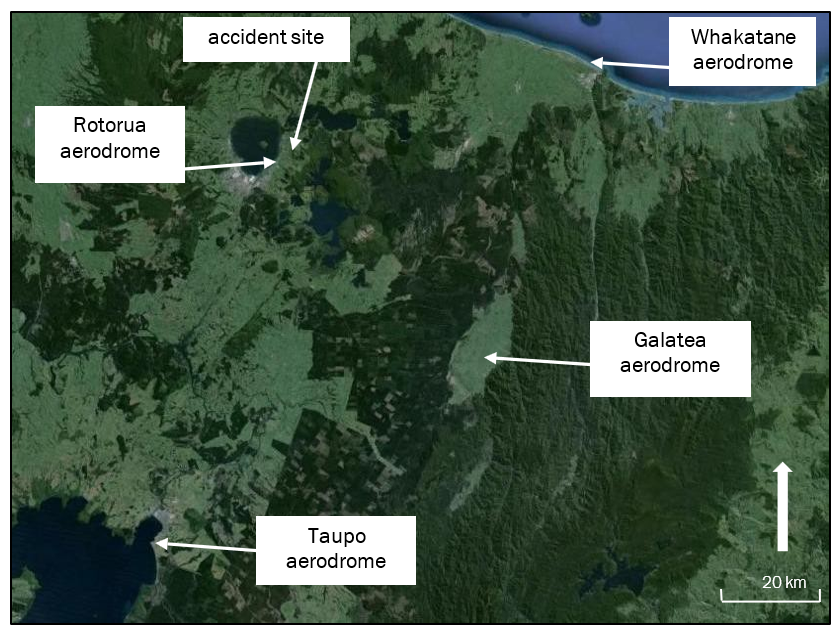

- On Thursday 14 April 2016, the day before the occurrence, the pilot and his instructor had flown the Guimbal Cabri, registered ZK-IIH (the helicopter), on a 2.7-hour instructional navigation flight from Taupo to the Wairarapa area. They had returned to Taupo the next morning, Friday 15 April. The pilot then continued with a solo navigation flight to consolidate the earlier lessons. The intended route was from Taupo to Rotorua, Whakatane, Galatea and back to Taupo (Figure 1). The pilot refuelled the helicopter fully, completed a pre-flight inspection and departed Taupo at about 1455 (timings are based on the pilot’s recollection and the air traffic service’s tower recordings and radar data).

- At 1525, the helicopter arrived at Rotorua. The pilot landed and prepared for the next leg of the flight, and sent a text message to his instructor to advise his progress. The helicopter departed from Rotorua at 1532, flying directly towards Whakatane.

- The pilot said he maintained a steady climb at 80 knots using a power setting of 80%. Less than 90 seconds after take-off he heard a loud bang followed by a ‘continuous clatter’. He advised the aerodrome tower that he had an engine problem and was returning to the aerodrome. During this time he entered a left turn towards the aerodrome and started a descent at the same power setting. He scanned the instruments and saw no warnings and no indication of a low main rotor speed.

- The pilot said that immediately after calling the tower he smelled smoke and soon thereafter saw smoke in the cabin. The smoke initially smelled like burning rubber. The pilot advised the tower that he was landing immediately and requested assistance. He landed in a paddock on a ridgeline, using power for the landing. He said he had no difficulty controlling the helicopter.

- The pilot shut down the engine with the mixture control lever, then turned off the ignition, fuel pump and electrical master control before he vacated the helicopter uninjured.

- Occupants of a house adjacent to the paddock were alerted to the approaching helicopter by the unusual sound it was making. They saw the helicopter fly past the house and heard what they described as a ‘clattering’ sound. One witness captured a five-second video recording of the helicopter after it landed in the paddock. The witnesses saw smoke being emitted from around the engine area of the helicopter, and the intensity of the smoke increase rapidly around the mast area at the top of the helicopter. After the pilot had escaped, the helicopter was quickly engulfed in flames. The still frames in Figures 2 and 3 are from the video recording.

- A rescue helicopter arrived at 1542, followed at 1554 by Fire Service personnel who extinguished the fire, but not before the helicopter was destroyed (Figure 4).

Personnel information

- The pilot held a private pilot licence (aeroplane) that had been issued in 1984. He had accrued 303 flight hours, but had not flown aeroplanes regularly in recent years. In July 2015, he had started flying helicopters with the intention of obtaining his private pilot licence (helicopter).

- The pilot had flown a total of 67.3 hours in helicopters at the time of the occurrence, with all but 3.4 flight hours in the Cabri. He was at the stage of completing his cross-country and mountain flying training before preparing for the flight test for the issue of the licence. The occurrence flight was a solo consolidation of exercises covered so far.

- The pilot held a current Class 2 medical certificate and said he was in good health and fit to fly at the time of the occurrence.

Aircraft information

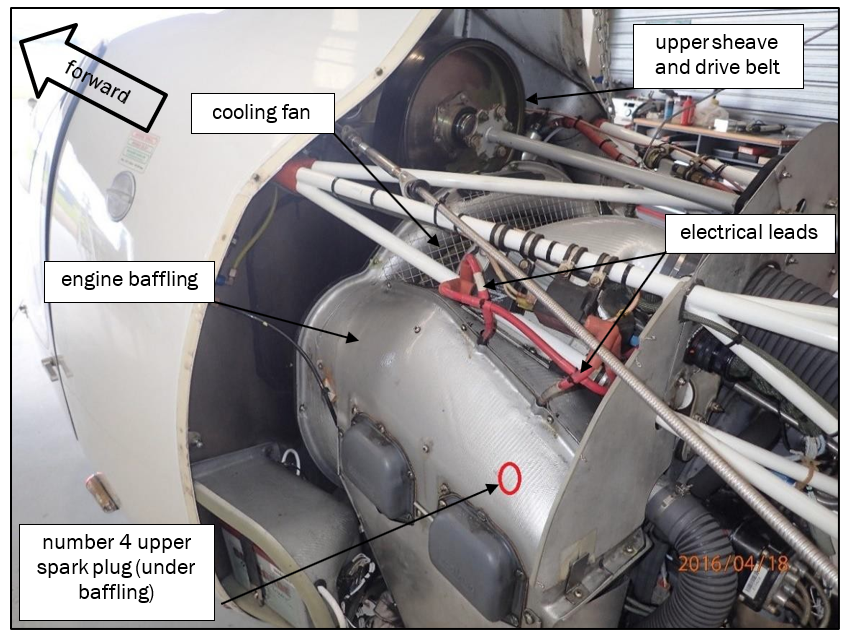

- The Cabri was a two-seat light helicopter, powered by a Lycoming O-360-J2A four cylinder piston engine, first certificated in late 2007. Engine power was delivered to the main gearbox by a single, 70-millimetre (mm) wide, heavy-duty rubber drive belt connecting lower and upper sheaves (A sheave is a pulley with a grooved wheel for holding a belt, wire rope or rope) (see Figure 5). The upper sheave transmitted power through a free-wheeling unit to the main and tail rotor gearboxes. Belt tension was controlled by a hydraulic actuator that used engine oil pressure to move the engine, and therefore the lower sheave, about a pivot point.

- The helicopter structure, apart from the engine frame, firewall and landing gear, was composed almost entirely of carbon-fibre composite materials. The main rotor blades were also constructed of carbon fibre. A fan positioned at the front of the engine provided cooling air that was forced around the engine by a fibreglass (the baffling was made of ‘glass fabric 300g/m2 with Epoxy resin Axson Epolam 2022’, sometimes called glass-fibre-reinforced plastic or glass-reinforced plastic) baffling, or shroud, positioned over the engine. Hot air was then directed down and away from the helicopter.

- Like nearly all aeronautical piston engines, each cylinder had two spark plugs. The engine was fitted with a dual ignition system. A conventional magneto (a magneto produces pulses of high voltage for a spark plug) fired the lower spark plugs on each cylinder, while a separate plasma, or electronic capacitor discharge, ignition system fired the upper spark plugs. The two systems used different spark plugs. The plasma system, manufactured by Light Speed Engineering used DENSO W24EMR-C spark plugs, had smaller-diameter threaded bases so required adapters when installed on the Lycoming engine. The W24EMR-C spark plugs also had different wear characteristics and had to be replaced after 200 hours of use.

- ZK-IIH had been manufactured in France in April 2010. The helicopter had initially been registered and flown in Germany before being imported to New Zealand in June 2015. The CAA had inspected the helicopter, determined that it conformed to the type certificate issued by EASA, and issued it with a New Zealand Airworthiness Certificate.

- An examination of the maintenance records for the helicopter confirmed that it had been maintained in accordance with its approved maintenance schedule. There were no reported defects that were considered relevant to this occurrence. The W24EMR-C spark plugs had been most recently replaced on 2 November 2015 and had accrued 121 hours of use.

Site and wreckage information

- The helicopter landed in a grassed paddock near the crest of a gentle slope, 2.8 km from Rotorua Aerodrome. The nearest building, a farmhouse, was about 100 metres away.

- The fire consumed most of the helicopter, leaving only the aft portion of the tail boom, including the tail rotor, undamaged. Several muffled explosions were heard during the course of the fire. These were likely to have been an exploding can of window cleaner stored in the locker behind the pilot, and the rupturing of the fuel tank. The fuel added to the intensity of the fire, which destroyed most of the non-metallic components about the engine and cabin. These included the drive belt, the rubber coating for the electrical leads and much of the cooling fan, scroll, ducting and engine baffling.

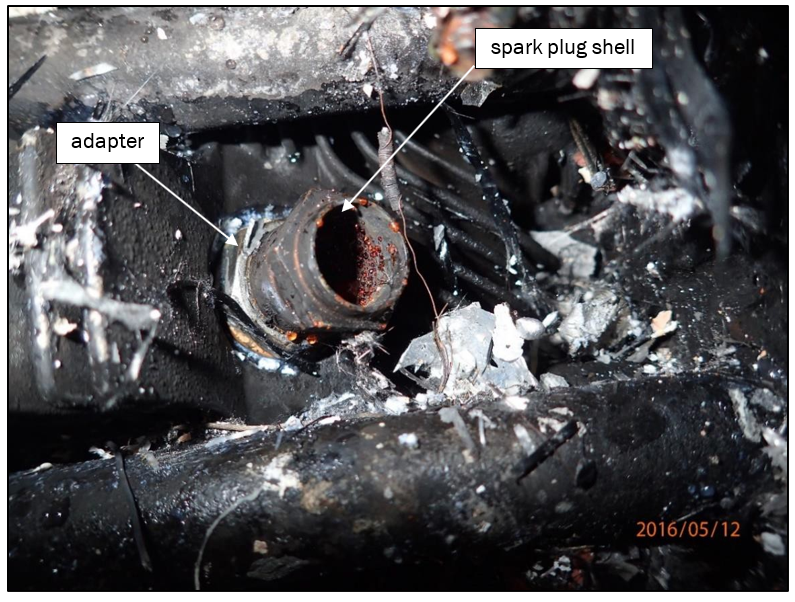

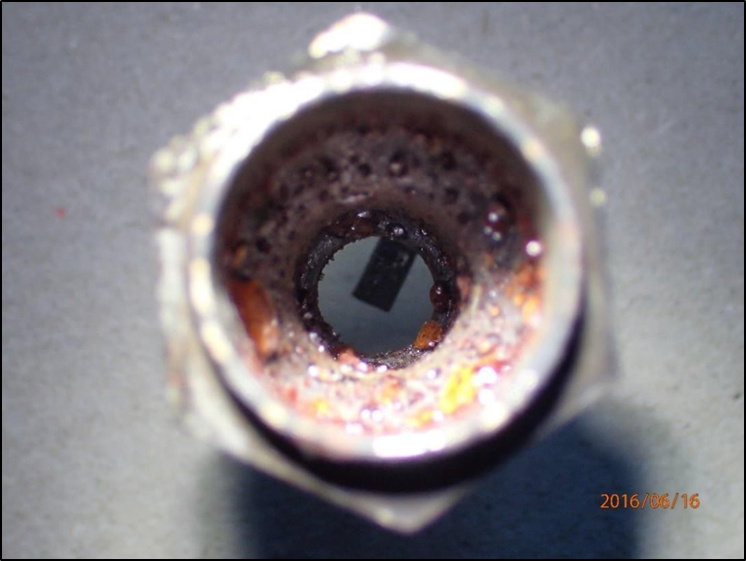

- The condition of the wreckage, in particular the state of the carbon-fibre ash, limited the examination of the wreckage at the site. The wreckage was therefore removed and taken to the Commission’s technical facility for a more controlled and detailed examination. During this examination it was discovered that the ceramic insulator containing the centre electrode for the number 4 cylinder upper spark plug was missing. Only the spark plug metal ‘shell’ was left in the cylinder (see Figure 6).

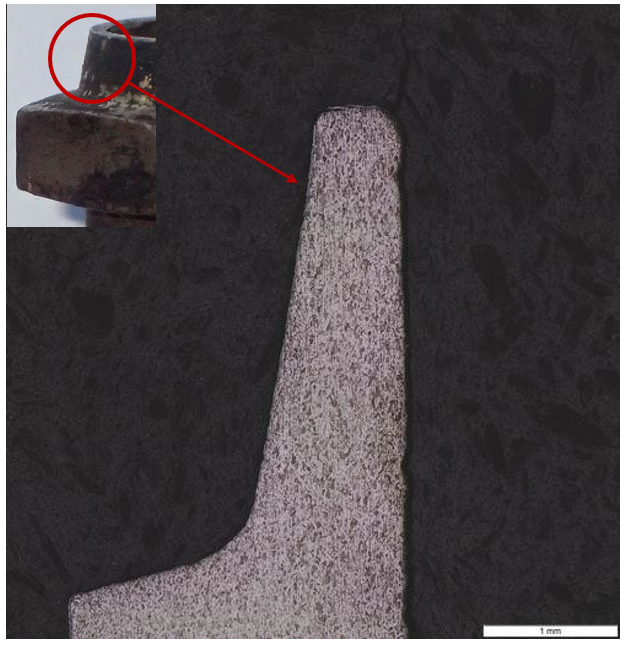

- A comparison of the spark plug shell in the number 4 cylinder and a new spark plug of the same type revealed a marked difference in the shape of the flange of the shell, which is normally swaged, or crimped, around the ceramic insulator (see Figure 7).

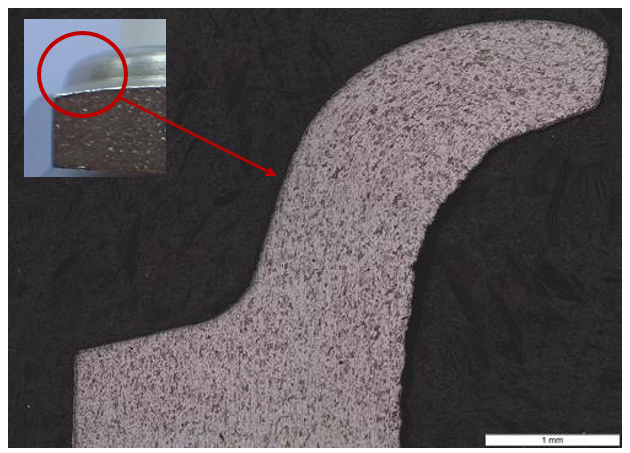

- Additionally, the spark plug shell was longer than the shell of a new spark plug and did not have the characteristic ‘bulge’ in the recess in the mid-section of the shell (see Figure 8). This bulge is made during manufacture when the shell is compressed in length by approximately 0.7 mm to form a tight internal seal around the ceramic insulator.

- The aperture in the spark plug shell, left by the missing ceramic insulator, was of a regular shape and provided an unobstructed passage into the combustion chamber for that cylinder (see Figure 9).

Tests and research

Helicopter manufacturer

- The helicopter manufacturer advised that it had performed a test to determine if the fire that erupted after landing could have caused the deformation seen on the number 4 cylinder upper spark plug. A new spark plug had been subjected to a high-temperature flame and monitored for any change to the swaging. No change was detected during this test.

Engine test run

- A Lycoming O-360 engine was installed on a test bed and initially run in normal configuration, with all eight spark plugs of the same type and in good condition. The engine parameters, including revolutions per minute (RPM), exhaust gas temperature and torque were recorded for reference. The engine was then shut down and the number 4 cylinder upper spark plug replaced with a DENSO W24EMR-C spark plug using the standard adapter. The ceramic insulator was removed from the spark plug to replicate the condition found after the accident.

- The engine started without difficulty and, once stabilised, the RPM was steadily increased to maximum. A distinctive ‘clattering’ noise was heard above the normal engine noise. A flame, approximately 20 centimetres (cm) in length, was emitted from the hole in the number 4 spark plug body. Using heat-sensing equipment, the temperature of the flame was measured to be approximately 870ºC. This was about 300ºC hotter than the exhaust gas temperature measured during the initial run.

- The engine was determined to be capable of normal operation through the full RPM range with the vibration within acceptable tolerances. The engineering staff who managed this test estimated there was a power loss of about 15% with the defective spark plug installed. See Appendix 1 for more detail of the engine test.

Metallurgy testing

- A range of DENSO W24EMR-C spark plugs was subjected to detailed metallurgical examination. These included the number 4 cylinder upper spark plug found after the accident and the other three DENSO spark plugs from the engine. The manufacturer provided a new serviceable spark plug and an unswaged spark plug taken from the relevant stage of the manufacturing process.

- The number 4 cylinder upper spark plug and the new serviceable spark plug both displayed the same circumferential markings typical of the machining that would have taken place during the initial stages of manufacture. The profiles of both spark plugs were also the same. There was no evidence of any mechanical deformation on the tapering boss for the number 4 cylinder upper spark plug.

-

The number 4 cylinder upper spark plug, another used spark plug and the new swaged spark plug were cross-sectioned to permit a comparison of their microstructures. The examination found the following:

The micro structures of the ex-service [used] and new swaged spark plugs shows vertical grain structure and other microstructural features in the metal forming the hex. This is the original microstructural orientation of the material stock used in manufacture. There is the obvious curvature and microstructural deformation from cold work in the swaged boss. There was no difference in the microstructure for the new and ex-service swaged spark plugs. The microstructure of the failed spark plug shows only the vertical inclusions in the hex material and extending into the tapered boss. No gross curvature or directional grain deformation from cold work was observed in the failed spark plug.

The lack of grain deformation in the failed spark plug provides evidence that the tapered boss at the top of the metal shell had never been swaged prior to service. (See Figures 10 and 11.)

Analysis Tātaritanga

Introduction

- The accident occurred without warning during the second flight of the day. The pilot’s prompt actions enabled him to land and vacate the helicopter without injury. The helicopter remained controllable throughout the emergency landing.

- The investigation determined that the number 4 cylinder upper spark plug had been manufactured incorrectly. This type of failure is extremely rare, and in a worldwide search no spark plugs with the same fault were found, either in service or held as spares. Because of the action taken by the CAA and EASA (see section 6), no further safety action was required.

- The following analysis discusses what happened and why the spark plug failed after only 121 hours in service.

What happened

- The insulator for the number 4 cylinder upper spark plug was not swaged during the manufacturing process, but it was initially held in place by a tight fit and an adhesive compound. However, after 121 hours of service the adhesive compound could not hold against the pressure within the cylinder and the insulator was ejected. The insulator almost certainly penetrated the fibreglass baffling. The insulator from the spark plug was not found.

- Hot combustion gases would have escaped through the hole created by the missing insulator, but the restrictive aperture retained a level of back pressure in the cylinder. This back pressure, coupled with the continuous ignition from the lower spark plug, would have maintained the combustion process in the cylinder. The unmuffled combustion gases would have generated the continuous and regular ‘clattering’ described by the pilot and witnesses. The same noise was heard during the testing conducted by the Commission.

- A jet of flame, at approximately 870ºC, would have been emitted from the hole in the upper spark plug shell and have impinged like a blowtorch flame directly onto the fibreglass baffling (the manufacturer advised that an epoxy resin with equivalent properties to the epoxy used in the construction of the baffling had a flash point greater than 150ºC and an auto-ignition temperature of more than 450ºC). Once the fibreglass resin was burning, the air from the engine-driven fan would have provided a continuous source of oxygen to sustain the fire. The carbon fibre fuselage structure, less than 20 cm away, would have ignited readily when it was exposed to the burning fibreglass.

- The fire progressed throughout the engine compartment, burning rubber-insulated components. This was very likely the source of the ‘burning rubber’ smell noticed by the pilot. A few minutes after the helicopter landed, the fire bypassed the forward firewall and ignited the fuel tank.

- Other possible ignition sources for the fire were considered, including a partial failure of the drive belt, the failure of another drive component and chaffing. None of these scenarios explained all of the symptoms described by the pilot, including the noise, no noticeable loss of power and no warning indications.

Spark plug

- The W24EMR-C spark plug was originally designed by DENSO in 1991 for use in motorcycle engines. In about 1992, Light Speed Engineering determined that the plug was suitable for its aviation ignition systems. Light Speed Engineering advised that it had sold 80,000 DENSO spark plugs with its plasma ignition systems, which, since 1988, had been installed in aircraft engines ranging from 65 horsepower to 650 horsepower. The Light Speed Engineering ignition system and W24EMR-C spark plugs were specified parts of the Cabri when it was certificated by EASA in 2007 (EASA Supplemental Type Certificate EASA E.S.1001).

- The four DENSO spark plugs found fitted to the engine had all been installed in November 2015, as the previous spark plugs were approaching the 200-hour limit. The four spark plugs had been taken from stock held by the maintenance provider and had been part of a larger consignment sourced from an approved aviation parts supplier (the holder of a certificate issued under Civil Aviation Rule Part 19, Subpart F). The parts supplier advised that as part of its quality control it occasionally inspected individual spark plugs within each batch prior to issuing a release note.

- Spark plugs generally do not have individual or batch identifying marks that would enable them to be traced back to the manufacturers. However, documentation revealed that the installed spark plugs had passed through several agents, including automotive suppliers in Australia and New Zealand, before reaching the aviation parts supplier. The link between the manufacturer and Australia could not be established and therefore the production date could not be identified. Although counterfeit automotive spark plugs are reportedly manufactured in large quantities overseas, the DENSO representatives who examined the four spark plugs were confident that they were genuine parts. This was later confirmed by DENSO Japan.

- DENSO contended that because of its quality control procedures, it would have been impossible for the failed spark plug to leave the factory unswaged. DENSO believed that the spark plug must have become unswaged during its 121 hours in service. However, a metallurgical examination of the spark plug disproved that hypothesis as it showed that the grain structure around the area of the boss had not been altered since its manufacture. The change in grain structure associated with the swaging process was absent, confirming that the failed plug had never been swaged. Further, in the test performed by Guimbal, despite applying a flame at over 1,000ºC, there was no deformation of the swaging.

- The manufacturing process described by the DENSO representatives included a number of quality assurance checks. However, because of the relatively small number of W24EMR-C spark plugs produced, between about 1,000 and 3,000 annually, the assembly process and quality control were intensively manual. That left open the opportunity for human error. No other faulty spark plugs were found, which tended to confirm that the failure rate was extremely low.

- The lack of swaging was obvious if the known defective number 4 cylinder upper spark plug was compared to similar spark plugs, but not when the plug was viewed on its own. The engineer who had last installed the set of spark plugs had not detected the anomaly, but their vigilance was likely to have been typical for any person performing that task. The authenticity and integrity of the spark plug would likely not have been in question, as it was a simple proprietary standard part, supplied new by an approved agent and accompanied by the appropriate documentation.

- The investigation identified several cases of other types of spark plug failing on motor vehicles and motorcycles. However, those were found to have been caused by broken insulators, probably as a result of the spark plugs being dropped.

- The engine manufacturer advised that a complete ejection of the centre insulator was a rare occurrence in aviation. In those cases, fatigue cracking of the crimped flange on the spark plug body allowed the insulator to be ejected under pressure. That scenario differed from the mode of failure in this incident and generally had involved spark plugs that had a very high time in service.

- During the investigation DENSO advised that it did not supply sparks plugs to Guimbal for use on the Cabri. The company later submitted that its subsidiary companies had not sold spark plugs to Guimbal or Light Speed Engineering. The DENSO product catalogue stated that the W24EMR-C spark plug was ‘not approved’ for use on aircraft. DENSO advised in January 2017 that the catalogue had been updated to state that DENSO spark plugs were ‘prohibited’ from use on aircraft, and that DENSO produced ‘automobile spark plugs which meet ISO [International Organization for Standardization] related only [to] automobile specs’.

- Guimbal advised that the W24EMR-C spark plugs were purchased directly from DENSO Netherlands or DENSO France, who were fully aware that the spark plugs were being installed in aircraft engines. Light Speed Engineering also said that DENSO was aware that the spark plugs were being used in aircraft engines.

- EASA advised that the statement of a manufacturer that a product is not approved for use in aviation ‘is a commercial statement without relevance for certification, because e.g. spark plugs have no independent “aviation approval” from an aviation authority and are always approved as part of an engine. Therefore, it is up to the TC [Type Certificate] or STC [Supplementary Type Certificate] holder to show that the chosen part is suitable for the intended use’. Neither Guimbal nor EASA intended to stop the use of the DENSO W24EMR-C spark plug with the Light Speed Engineering ignition system.

Findings Ngā kitenga

- The in-flight fire was initiated by the ejection of the number 4 cylinder upper spark plug centre insulator.

- The engine continued to operate, which allowed hot combustion gases from the number 4 cylinder to impinge upon the combustible fibreglass baffling and then the carbon-fibre fuselage.

- The pilot’s prompt actions were appropriate and commendable. The immediate landing combined with the protection provided by the engine bay firewall prevented a more serious outcome.

- The spark plug failed because it had not been swaged during the manufacturing process.

- The failed spark plug was a genuine part that had been approved by the relevant airworthiness authority for use as a part of the helicopter’s ignition system.

- This type of failure with spark plugs is so rare that it does not have significant implications for aviation safety.

Safety issues and remedial action Ngā take haumanu me ngā mahi whakatika

General

-

The Commission classifies safety actions by two types:

(a) safety actions taken by the regulator or an operator to address safety issues identified by the Commission during an inquiry that would otherwise result in the Commission issuing a recommendation

(b) safety actions taken by the regulator or an operator to address other safety issues that would not normally result in the Commission issuing a recommendation.

Safety actions addressing safety issues identified during an inquiry

- On 10 August 2016, in response to advice from the Commission, the Director of Civil Aviation issued Continuing Airworthiness Notice CAN 74-002, which strongly recommended that operators/maintenance providers inspect all DENSO W24EMR-C spark plugs, whether installed in engines or held in stock, for defects.

- On 1 September 2016, EASA, as the airworthiness authority for the Guimbal Cabri helicopter, issued a Safety Information Bulletin recommending that operators of Cabri helicopters inspect DENSO W24EMR-C spark plugs for serviceability (EASA, 2016). On the same day Guimbal issued Service Bulletin SB16-022A, recommending that operators check all installed and new DENSO W24EMR-C spark plugs, and repeat the inspections at all installations thereafter. Reference was made to the relevant sections of the maintenance manual for the helicopter.

- No other DENSO spark plugs with this fault were identified, therefore the quality defect was an extremely rare occurrence.

Safety actions addressing other safety issues

- None identified.

Recommendations Ngā tūtohutanga

General

- The Commission may issue, or give notice of, recommendations to any person or organisation that it considers the most appropriate to address the identified safety issues, depending on whether these safety issues are applicable to a single operator only or to the wider transport sector.

- In this case the Commission made no recommendation. The actions taken by the CAA and the manufacturer of the helicopter, in conjunction with EASA, were considered sufficient to identify any other defective spark plugs.

Key lessons Ngā akoranga matua

- Maintenance personnel need to be vigilant for product anomalies when installing components onto aircraft, even when the components come from approved suppliers.

Glossary Kuputaka

- Auto-ignition temperature

- The lowest temperature at which a material will spontaneously ignite in normal atmosphere without an external source of ignition.

- Flash point

- The lowest temperature at which vapours of a material will ignite when given an ignition source

- Swaging

- A forging process in which cold metal is bent into a desired shape

- RPM

- Revolutions per minute

- ICAO

- International Civil Aviation Organization

- EASA

- European Union Aviation Safety Administration

Data summary Whakarāpopoto raraunga

Details

latitude: 38° 5.2´ south

longitude: 176° 20.7´ east

Citations Ngā tohutoru

EASA, 2016 European Aviation Safety Agency Safety Information Bulletin, Airworthiness, SIB No: 2016-15, issued 30 September 2016 – Improperly Crimped Spark Plugs.

Appendix 1. Guimbal Cabri G2, engine test run, Rotorua, 6 October 2016

Objective

The objective of the engine test run was to record data that would allow an assessment of the implications of operating the Lycoming O-360 engine fitted to the Guimbal Cabri G2 helicopter, with a defective DENSO W24EMR-C spark plug in the number 4 cylinder upper position.

Test procedure

The engine test rig was equipped with a magnetic brake dynamometer and full digital diagnostic capabilities, allowing the recording and plotting of all significant parameters during the engine run. The test was performed by the New Zealand Lycoming field representative.

A DENSO W24EMR-C spark plug had previously been prepared for the test procedure by removing the ceramic insulator from the spark plug shell. An adaptor of the type normally used with the W24EMR-C spark plug had been sourced, which permitted the smaller-diameter, 12-mm automotive-type spark plug shell to be installed in place of the standard ¾-inch (19 mm) aviation-type spark plug.

A video camera was mounted to the rig in a suitable position to record the flame expected to be emitted from the aperture in the defective number 4 cylinder upper spark plug shell.

At the commencement of the testing, the engine was initially run in the rig in normal configuration, i.e. with all upper spark plugs in good working order. The parameters for this engine run were recorded for reference and comparative purposes.

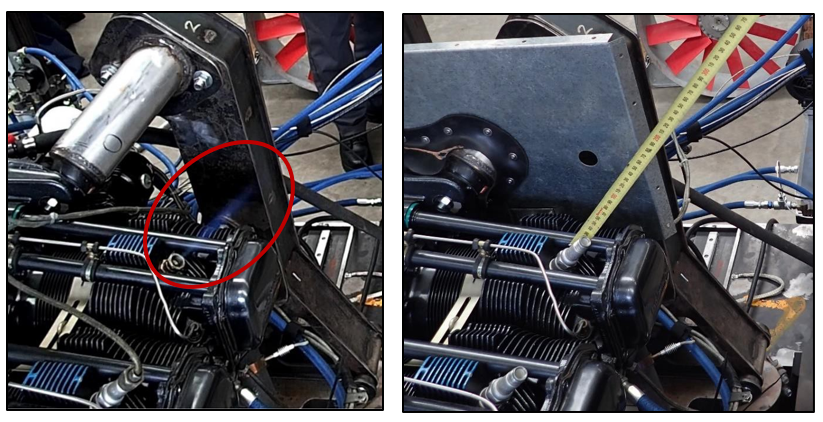

The engine was shut down and the number 4 cylinder upper spark plug was removed. The adapter and the DENSO W24EMR-C spark plug shell with the centre insulator removed were then fitted (see Figure 1).

The engine was started again and once stabilised, the throttle was progressively increased. A visible flame emitted from the spark plug body and this was recorded by a video camera mounted to the test rig (see Figure 2).

At the end of the engine test run a still photograph was taken, with a tape measure placed adjacent to the path of the emitted flame (see Figure 3). This allowed an estimate to be made of the length of flame shown in the video recording.

The parameters for both the reference run and the test run were recorded and compared.

Although the temperature of the flame was not able to be measured directly, when the engine was running at the maximum test RPM of 2,700, the maximum stabilised temperature of the exhaust in the number 4 engine exhaust manifold was around 1,600ºF (870ºC). This was 300ºF (150ºC) hotter than the number 4 exhaust manifold temperature during the reference engine run.

The engine delivered a maximum 229 Nm (newton metres) of torque at 25 inches (6.35 cm) of manifold pressure during the datum engine run. During the test run the engine was producing 120 Nm of torque at 19 inches (4.83 cm) of manifold pressure. The increasing number 4 cylinder head temperature required that the test run be terminated to prevent any engine damage.

Findings

- The engine was able to be started and run with the defective number 4 cylinder upper spark plug.

- A jet of flame greater than 200 mm in length and at a temperature of approximately 1,600ºF (870ºC) was emitted from the hole in the number 4 cylinder upper spark plug body.

- The engine was capable of normal operation through the RPM range and the levels of vibration observed when operating with a defective upper spark plug were acceptable.

- The Lycoming field representative estimated that the total engine power loss from the defective spark plug condition was in the order of 15%.