Molten material from the hot work caused fire, burned 7 days, extensive damage to high-value fibre-glass cargo, no fatalities, no serious injuries. TAIC calls on Fire and Emergency NZ to improve training in fighting fires on ships. Crucial tactics (close cargo hold cover, release CO2 into hold) weren’t done. Valuable time lost because people lacked a good understanding of each other’s roles and objectives. One new recommendation to Pacific International Lines to address safety issues over fire response and gas cutting hot work.

Executive summary Tuhinga whakarāpopoto

What happened

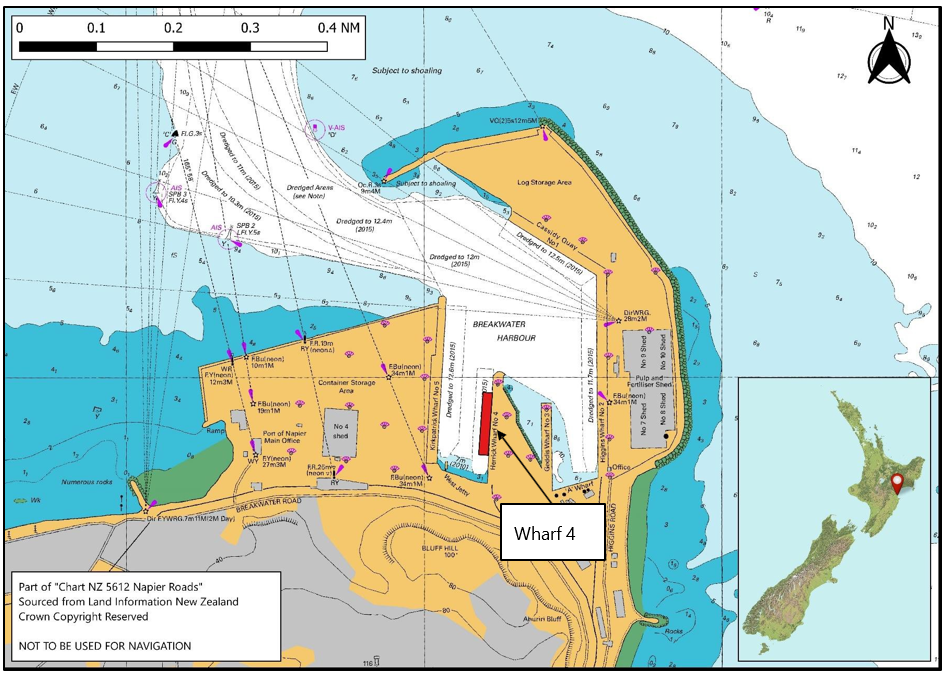

- During the morning of 18 December 2020, cargo discharge operations were underway on board the Kota Bahagia at Wharf 4, Napier Port. Four people working in number 2 cargo hold discovered a rapidly evolving fire in the cargo hold and evacuated immediately. With the local fire service in attendance, the fire was suppressed using the on-board carbon dioxide fire-suppression system. The fire was officially declared as extinguished on 24 December 2020. There were no fatalities or injuries, but there was extensive damage to number 2 cargo hold and high-value project cargo in the hold.

Why it happened

- Molten material, ejected during gas-cutting activities, very likely ignited dry sawdust nearby, which created a smouldering fire that ignited the polyvinyl-chloride tarpaulins and other combustible components of the fibre-glass project cargo.

- Hot-work precautions were not fully implemented by the ship’s crew.

- The tight stowage of the project cargo hampered the view and access of the person assisting with the gas-cutting operations. Consequently, in some locations there was no way to control effectively the dispersal of molten material ejected during the gas-cutting.

- Fire and Emergency New Zealand responders did not initially give due regard to the master’s command status and knowledge of the ship and its systems. Valuable time was lost as the master attempted to convey their intended tactics to the officer in charge of the unified command team.

- The hatch cover could not be closed until a crane wire and container spreader had been hoisted out of the cargo hold. As a consequence there was a delay in the activation of the vessel’s fixed carbon dioxide fire-extinguishing system and the release of carbon dioxide into the cargo hold.

What we can learn

- Risk assessments and job safety analyses for hot work must give consideration to any constraints in the area where the hot work is to be carried out. The risk assessment should be applied systematically with monitoring to ensure the control measures are appropriate and effective.

- A shipboard fire response is based on the vessel’s design, fire protection systems and crew numbers. During a co-ordinated incident response involving ship fires in a New Zealand port, the ship’s master might not be the incident controller. However, the master retains the overriding authority to make, and the responsibility for making, decisions regarding the safety and security of the vessel. The master is responsible for the safety of life on board, the care of the cargo and protecting the marine environment from ship-borne pollution. Fire and emergency responders need to take this into account as part of their responses to ship fires.

Who may benefit

- Vessel operators and crew, charterers, freight forwarders, shore-based marine engineering contractors, maritime training facilities and shore-based emergency response agencies may all benefit from the findings in this report.

Factual information Pārongo pono

Narrative

- At 1700 on 17 December 2020, the Kota Bahagia berthed alongside at Wharf 4, Napier Port, New Zealand. The cargo for discharge at Napier included wind turbine components that had been carried from Taicang, China

- Shore-based staff, including stevedores and fitters from a local engineering company, boarded the vessel to commence unlashing the cargo in preparation for discharge.

- Cargo-discharge operations commenced at 2212 and continued overnight.

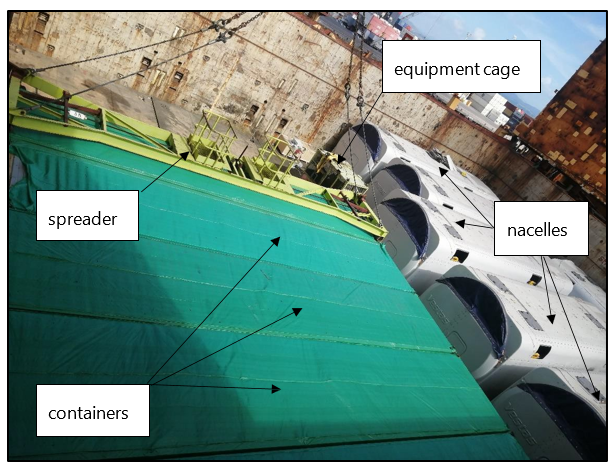

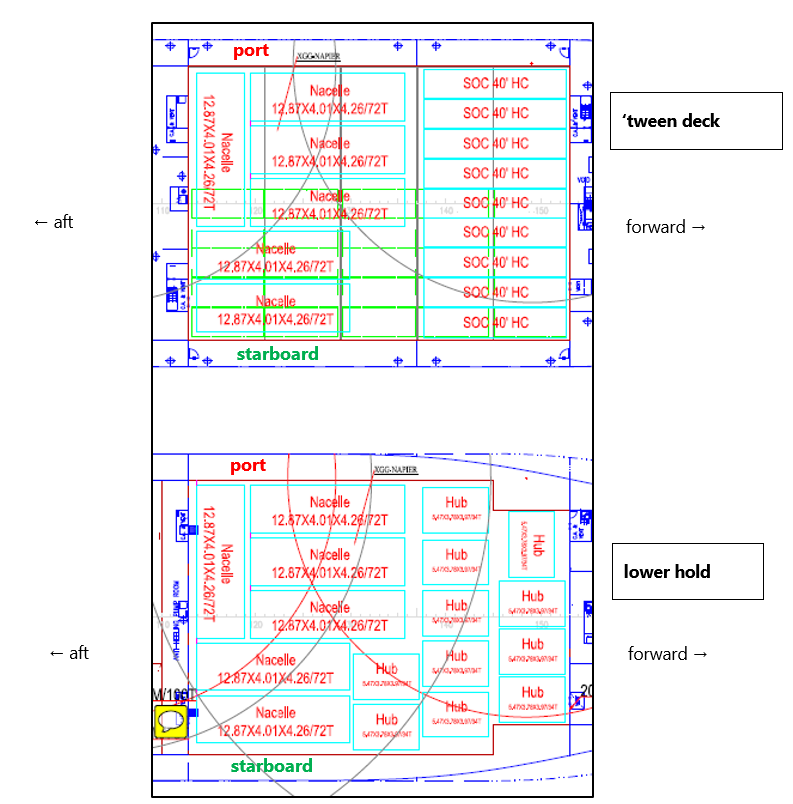

- At about 0648 on 18 December 2020, two fitters from a local engineering company commenced hot work in number 2 cargo hold ‘tween deck (see Figure 3). The number 2 ‘tween deck cargo consisted of nine 40-foot (12-metre) containers at the forward end and six wind turbine nacelles at the aft end (see Figure 5).

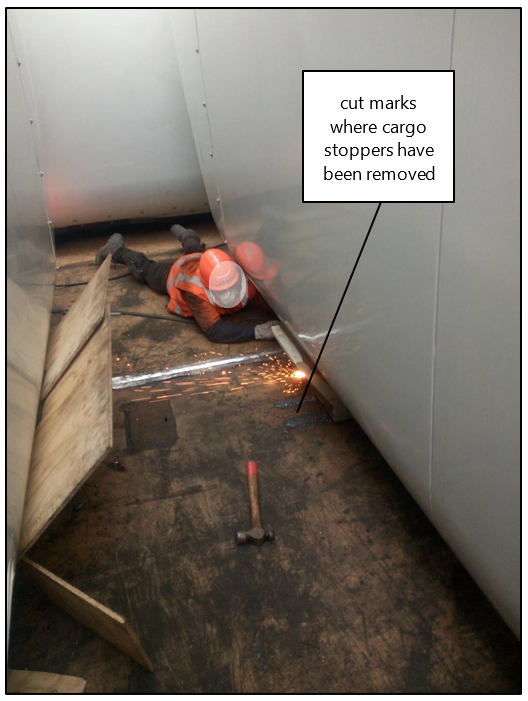

- Specifically, the fitters’ task was to remove the cargo stoppers that had been welded to the ‘tween deck pontoons for securing the cargo. The removal of the cargo stoppers required oxygen/acetylene gas-cutting. One of the fitters carried out the cutting operations. The other watched for stray sparks and ejections of hot material, and placed the offcuts in a steel bucket after cooling them with water from a portable fire extinguisher.

- The master and the harbourmaster had issued permits allowing this hot work to take place. The fitters had completed their own job safety analysis prior to the vessel’s arrival.

- At about 0942, stevedores commenced discharging containers from number 2 cargo hold. Two stevedores were located inside number 2 cargo hold and one stevedore was driving the vessel’s crane. After discharging four containers, the stevedores took their morning-tea break. No containers were discharged between 1000 and 1030. During this time the master of the Kota Bahagia conducted rounds of the deck and found that all was quiet. The master did not see anybody in number 2 cargo hold. However, the fitters had remained in the cargo hold to finish cutting off the remaining cargo stoppers while the stevedores were on their break.

- After resuming cargo operations and discharging one container, one of the stevedores, who was standing next to the remaining containers, noticed white smoke in number 2 cargo hold. The two stevedores and two fitters in the hold discussed whether it was dust or smoke. The fitters had completed their work in the ‘tween deck and were stowing the gas-cutting equipment so that it could be removed from the cargo hold. Shortly afterward, one of the stevedores repeated that it could be smoke. At about 1039, as the crane driver returned the container spreader to the cargo hold, the smoke turned black and thickened and the workers in the cargo hold realised there was a fire. Within 10 to 20 seconds the smoke became very thick and the workers in the cargo hold had to pass in close proximity to the fire to get out of the hold.

- By 1043 all the workers were out of the cargo hold and the crane driver had stopped the crane, called “fire” over the radio and vacated the crane cab. They all went down to the quay and headed towards the designated muster point for shore-based staff.

- The deck cadet, who was on gangway duty, called the chief officer on the radio to report that there was smoke coming from number 2 cargo hold. The chief officer, who was on deck directing the crew as they removed the pontoons from number 4 cargo hold, told the cadet to activate the fire alarm. The master, who had been resting in the master’s cabin, heard an alarm sounding on the bridge at about the same time. The master went to the bridge to investigate the cause of the alarm and saw that the cargo hold smoke-detection system had been activated.

- The chief officer went forward, towards number 2 cargo hold, and saw workers who were not crew members running aft towards the gangway. The cargo superintendent was the only other person on deck near number 2 hatch whom the chief officer noticed. The chief officer asked the cargo superintendent if the shore workers had all gone ashore and determined that there were no workers left inside number 2 cargo hold.

- By 1045 thick black smoke was visible coming out of number 2 cargo hold and thevessel’s fire alarm was ringing. The chief officer and the cargo superintendent started to rig fire hoses on deck while the vessel’s crew assembled at their emergency muster stations. The Kota Bahagia’s fire response plan designated the crew into five emergency parties with assembly points on the bridge, the engine control room and on deck in front of the accommodation. The crew who assembled on deck made up three of the emergency parties – two firefighting parties and one first-aid party. Once the crew had assembled in their respective emergency parties, the master co-ordinated the initial fire response actions to determine the extent of the fire and the best way to suppress it.

- At 1053 the first Fire and Emergency New Zealand (NZ) resources arrived at the port. The senior fire service officer called out to the chief officer to send all personnel ashore. The chief officer relayed this instruction to the master, and at about 1100 all crew were sent down to the quay. The vessel’s firefighting plan was handed over to the fire service. Hoses were rigged on the quay to deliver boundary cooling water to the vessel’s side.

- The crew assembled on the quay and a head count was carried out. The master and the chief officer returned on board to phone the vessel’s shore-based management, but were ordered ashore again by the senior fire officer.

- At about 1115 two of Napier Port’s pilots arrived at the port and offered to assist with maritime advice. Shortly afterwards, the Fire and Emergency NZ officer in charge set up a command team that included the master, the ship’s chief engineer, Napier Port’s safety and emergency management advisor and two pilots.

- Crew from the Kota Bahagia who were not involved in the fire response were marshalled by officers from the New Zealand Customs Service. Due to New Zealand’s COVID-19 border order (see https://www.legislation.govt.nz/regulation/public/2020/0240/latest/LMS403572.html COVID-19 Public Health Response (Maritime Border) Order (No 2) 2020) that was in place at the time, the crew were required to remain in isolation or quarantine until the necessary risk ratings had been completed. Maritime border officers (Assistant Customs Officers – Maritime Border) assisted the Customs officers with the intention of minimising any potential COVID-19 spread by reducing or removing any contact between the vessel’s crew and any emergency services and shore-based workers operating in the port.

- At 1131, Napier Port’s tug Kaweka was sent to the offshore side of the Kota Bahagia to assist with the firefighting effort and provide boundary cooling as and when possible.

- At about 1200, with agreement from the command team, crew members were permitted to board the vessel with shore-based firefighters. Their mission was to operate the crane and clear the crane wire and container spreader from the hatch opening. This would enable them to close the hatch covers and then release into the hold carbon dioxide (CO2) from the vessel’s fixed CO2 fire-extinguishing system.

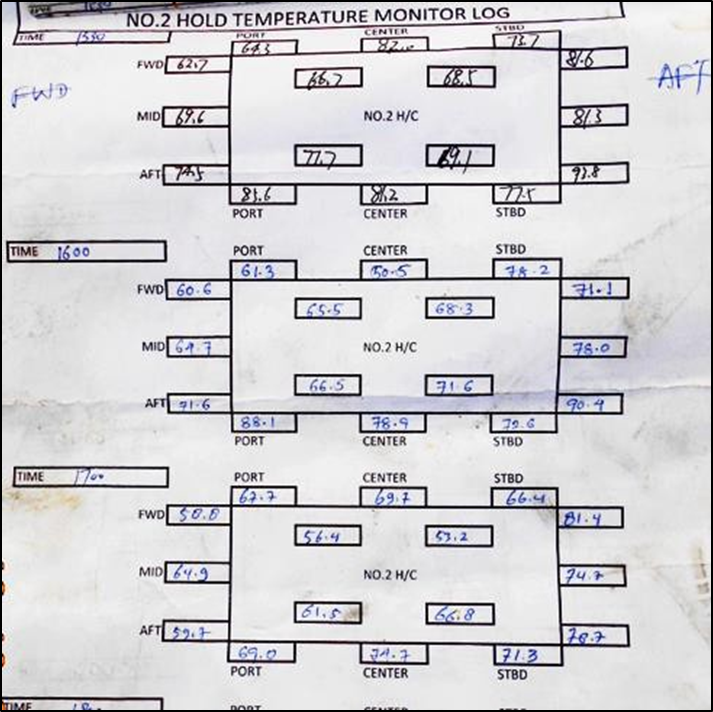

- At about 1209 the crane wire and the container spreader were cleared from the hatchway. At 1214 the hatch covers were closed, and about 10 minutes later 67 bottles of CO2 were released into number 2 cargo hold. After the CO2 was released, it was observed from the tug that the fire may have spread. Crew members accompanied by firefighters went on board to secure the hatch covers of cargo holds forward of number 2 cargo hold. The crew also conducted temperature checks using a thermal imaging camera, and recorded hatch coaming temperatures (see Figure 7).

- Shortly before 1400, the Fire and Emergency NZ officer in charge gave approval for the ship’s crew to use the onboard sanitary facilities. A final check was carried out using a thermal imaging camera on board the Kaweka to ensure that the cargo hold temperature continued to decrease. At 1401 permission was given for normal operations to resume at the port except for Wharf 4 and the adjacent log yard.

- Ongoing monitoring of the cargo hold temperature in the following days showed that the temperature was decreasing towards ambient.

- On the morning of 24 December the Kota Bahagia shifted to Wharf 1. The hatch cover of number 2 cargo hold was opened and a drone was flown over the open hatch. Fire and Emergency NZ officially declared the fire to be out and handed the fire site responsibility back to the master of the Kota Bahagia.

Personnel information

- The master had 20 years of command experience and over 38 years of maritime experience. After graduating in 1982, the master’s first command had been gained in 2000. The master had joined the Kota Bahagia in Turkey on 14 September 2020.

- The chief officer held a chief mate’s certificate of competency and had joined the Kota Bahagia on 28 July 2020. After completing a cadetship with Pacific International Lines (PIL) in 2012, the chief officer had completed further training in 2018-2019 to gain a chief mate’s certificate of competency.

Vessel information

- The Kota Bahagia was built in China in 2011 and registered in Singapore. A multi-purpose general cargo vessel, it could carry breakbulk and containerised cargoes. It had four cargo holds that could be divided into lower and ‘tween deck stowage spaces. The vessel was geared with three specialised cranes rated to lift a maximum of 100 tonnes each. This flexibility and heavy-lift capability made the Kota Bahagia suitable for carrying project cargoes of heavy machinery and components.

Site and wreckage information

Cargo, stowage and lashings

- The fire was contained within number 2 cargo hold, and both the lower hold and the ‘tween deck were affected by fire, heat and smoke.

- The cargo stowed in number 2 lower hold consisted of 11 wind turbine rotor hubs and six wind turbine nacelles. The number 2 ‘tween deck cargo consisted of six wind turbine nacelles and nine 40-foot (12-metre) containers (see Figure 8).

- The International Maritime Organization sets out the stowage and securing requirements for cargoes transported by sea in the Code of Safe Practice for Cargo Stowage and Securing (the CSS Code). Project cargo, such as the wind turbine components carried by the Kota Bahagia, is subject to the requirements of Chapter 5 (Non-standardized stowage and securing) and Annex 5 (safe stowage and securing of heavy cargo items such as locomotives, transformers, etc.) of the CSS Code.

- Annex 5 requires heavy cargoes to be secured against sliding and tipping and states that “Whenever possible, timber should be used between the stowage surface and the bottom of the unit in order to increase friction”. Annex 5 also recommends the use of timber shoring, welded fittings or “other appropriate means” when lashing restraints cannot be placed suitably. Cargo stoppers/sea lashings, such as those used on the Kota Bahagia (see Figure 9), are commonly used to secure non-standardised heavy cargoes.

- For the sea voyage between China and New Zealand, the cargo was secured using a combination of cargo lashing chains and strops along with sea lashings (cargo stoppers) (see Figure 9).

- After the fire had been declared extinct, number 2 cargo hold was closed until a complete risk assessment and safe-entry plan was developed.

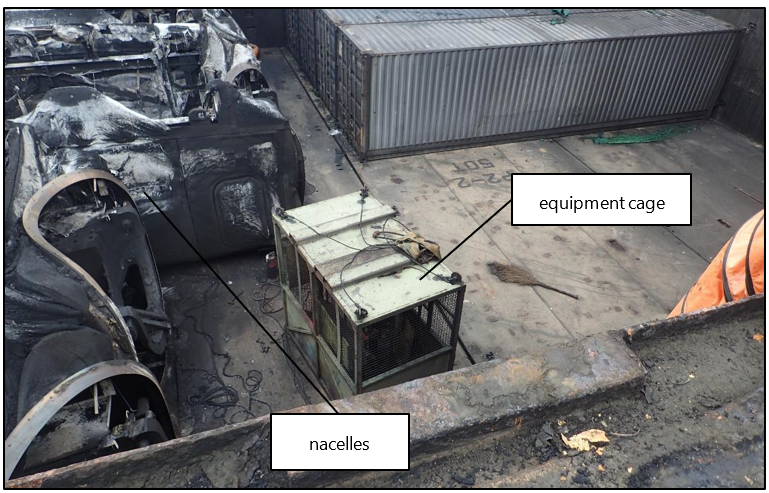

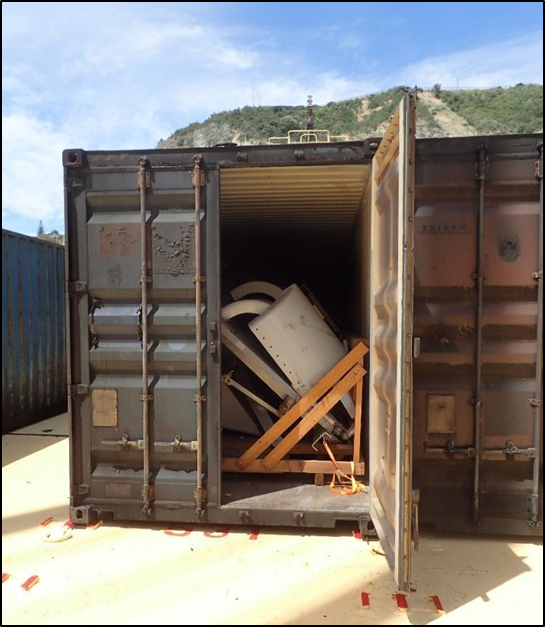

- The wind turbine hubs and nacelles in number 2 cargo hold were all destroyed by the fire directly or by its heat (see Figures 10 and 13-15). The containers exhibited smoke-staining and radiant heat damage to external painted surfaces. On visual inspection there was little damage to the cargo carried within the containers (see Figure 11).

- Low-melting-point items in number 2 cargo hold, such as plastic fittings on electrical cables, suffered heat damage. The welding equipment was mainly undamaged and timber items further away from the seat of the fire were also relatively undamaged (see Figures 10, 11 and 12).

- The timber dunnage used on board the Kota Bahagia was a soft and dry type of timber. Surplus dunnage was found in and around the cargo holds and there were deposits of sawdust present in number 2 cargo hold on the ‘tween deck and in the lower hold. Small particles of sawdust from this timber could have been ignited by hot material ejected during the gas-cutting activities.

Previous occurrences

- The Australian Transport Safety Bureau (ATSB) and the United States National Transportation Safety Board (NTSB) have investigated cargo hold fires that were found to have involved hot work, cargo stoppers and project cargo. The published investigation reports of the following incidents all show similarities with the fire incident on board the Kota Bahagia:

- BBC Islander, Dampier, Western Australia, 14 August 2007, investigated by the ATSB (Marine Occurrence Investigation No. 245: Independent investigation into the fire on board the Antigua and Barbuda registered general cargo ship BBC Islander at Dampier, Western Australia, 14 August 2007, ATSB)

- BBC Baltic, Port Hedland, Western Australia, 26 January 2012, investigated by the ATSB (MO-2012-002: Cargo hold fire on board BBC Baltic at Port Hedland, Western Australia, 26 January 2012, ATSB)

- BBC Xingang, Newcastle, New South Wales, 11 December 2017, investigated by the ATSB (337-MO-2017-011: Fire on board BBC Xingang at Newcastle, New South Wales, 11 December 2017, ATSB)

- Chipolbrok Moon, Houston, Texas, 23 May 2018, investigated by the NTSB (Marine Accident Brief 19/07: Fire aboard cargo ship Chipolbrok Moon, 23 May 2018, NTSB)

- The ATSB is currently investigating a cargo hold fire on board the general cargo vessel BBC Rhonetal at Port Hedland on 25 March 2021 (MO-2021-002: Fire on board BBC Rhonetal while berthed in Port Hedland on 25 March 2021). Shortly before the fire broke out, hot work operations were undertaken to remove cargo-securing points from the cargo hold.

Organisational information

Pacific International Lines

- At the time of the incident, the Kota Bahagia was operated by PIL, a privately owned, Singapore-based shipping company. The vessel was chartered by HongFa Shipping for the sea phase of the shipment for freight-forwarding company DSV.

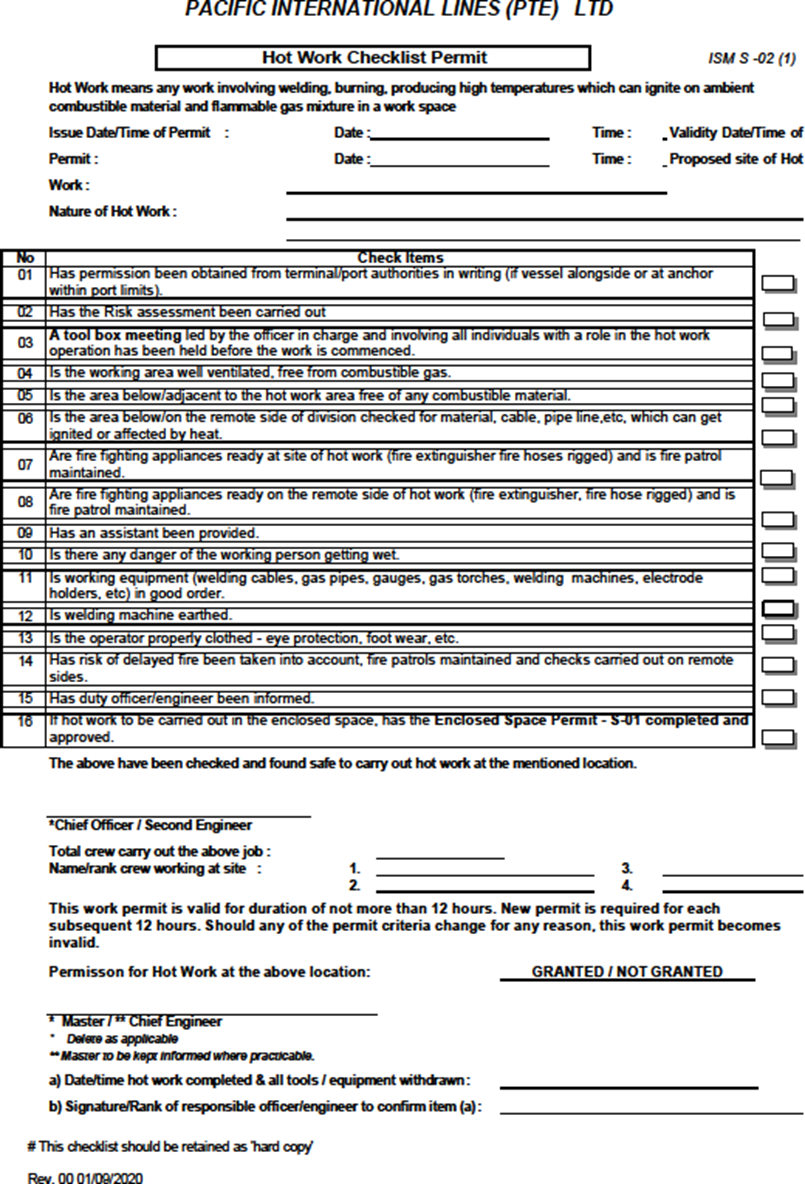

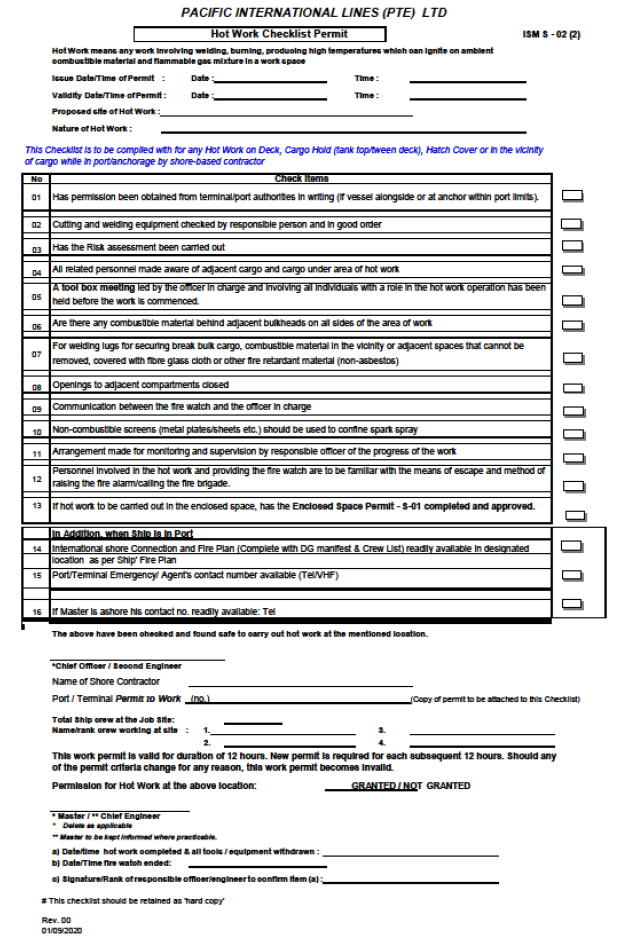

- PIL’s safety-management system included policies and procedures developed in accordance with the International Safety Management Code as required by Chapter IX (Management for the Safe Operation of Ships) of the International Convention for the Safety of Life at Sea, 1974. PIL’s safety management system set out the responsibilities of personnel on board PIL-managed vessels and PIL personnel with shore-based vessel-management positions. The safety-management system included a Safety and Emergency Manual that contained information and instructions for crew on when and how to use the permit-to-work system for high-risk work. Hot work was identified as one of these work activities and was not permitted on board a vessel without the completion of a permit to work and the master’s permission.

- PIL had adopted the practices of the United Kingdom Code of Safe Working Practice for Merchant Seafarers (COSWP) as the industry standard expected on board. COSWP recommends that any hot work activities that occur outside a ship’s workshop be the subject of permits to work. The code also recommends that, prior to starting any hot work, the area is checked to ensure that no combustible materials are in, below or adjacent to the work area, and dunnage should be removed where possible. The code also states that hot work should be properly supervised and kept under regular observation. Suitable fire extinguishers should be kept at hand, ready for use during an operation. A person with a suitable extinguisher should also be stationed to keep watch on areas that may be affected that are not visible to the person doing the hot work (UK COSWP 24.2.9).

- PIL’s procedures for conducting hot work required additional precautions, including the preparation and pressurisation of fire hoses and the maintenance of a fire watch for two hours after hot work had been completed.

Fire and Emergency New Zealand

- New Zealand’s fire service is a Crown entity operated under the provisions of the Fire and Emergency New Zealand Act 2017. The Act sets out the functions, operating principles and powers of authorised persons attending an emergency event.

- The operating principles of Fire and Emergency NZ include working co-operatively and collaboratively with other relevant organisations, (Section 13, Fire and Emergency New Zealand Act 2017) and the Act places importance on engagement with organisations that seek the assistance of Fire and Emergency NZ. The New Zealand Government has adopted an emergency management framework called the ‘Coordinated Incident Management System’ (CIMS) to enable emergency services, civil defence organisations and local council response teams, among others, to work together in an emergency under a common, scalable framework.

Analysis Tātaritanga

Introduction

- On 18 December 2020, a fire broke out in number 2 cargo hold on the Kota Bahagia. There were no fatalities or injuries, but high-value project cargo in number 2 cargo hold was destroyed. Shortly before the fire was discovered, shore-based contractors had been conducting oxygen/acetylene cutting operations to remove cargo-securing devices.

- The following section analyses the circumstances surrounding the event to identify those factors that increased the likelihood of the event occurring or increased the severity of its outcome. It also examines any safety issues that have the potential to adversely affect future operations.

Hot work on board

Safety issue: At the time of the incident the ship’s crew did not implement the requirements set out in PIL’s safety management system and in the harbourmaster’s hot-work permit and ensure the safe execution and supervision of hot work carried out by shore-based contractors on board the vessel.

- Following the extinction of the fire, number 2 cargo hold and its contents were examined forensically. Burn patterns and damage comparisons provided indicators of the location of the fire’s origin. The most damage was sustained on the ‘tween deck, with mainly heat and smoke damage in the lower hold.

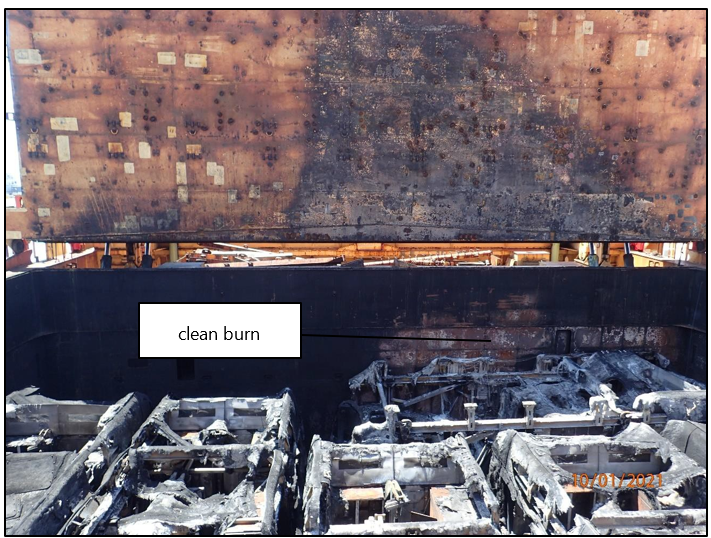

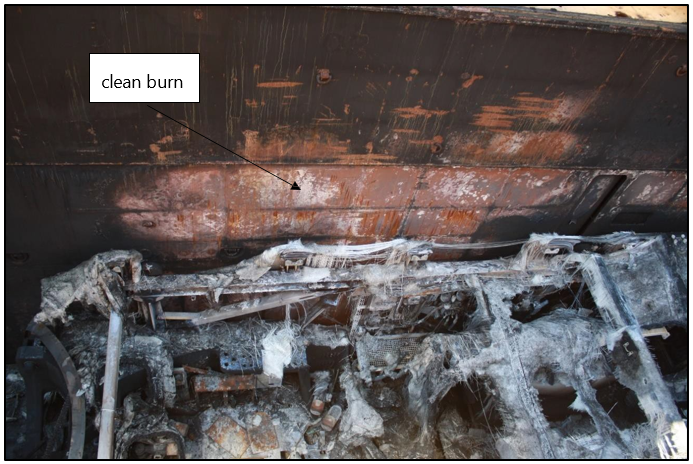

- The nacelle that was stowed athwartship, port side, at the aft end of the ‘tween deck sustained the most damage (see Figures 13 and 14) and it is very likely that the fire originated either underneath this nacelle or between the nacelle and the side of the cargo hold. The presence of clean burn33 on the side of the cargo hold showed that the fire was so hot in this location that the soot deposits were burnt off.

- The Transport Accident Investigation Commission (Commission) engaged the services of a specialist fire investigator to complete a report on the origin and cause of the fire. The fire investigator’s conclusion was that the most likely ignition sequence was a hot slag bead from the gas-cutting igniting the sawdust from the dunnage that was used between the cargo and the steel deck, resulting in a smouldering fire.

- An examination of the gas-cutting equipment verified interview statements that the gas cutting had been completed and the fitters had started to pack away their equipment when the fire was noticed. The oxygen and acetylene bottles were all closed. Although witnesses reported that they heard the gas bottles exploding, none of the welding gas bottles exploded. It is very likely that any explosion heard related to the pontoon beneath the seat of the fire, weakened by the extreme heat and rupturing as the air inside the structure heated and expanded. The resulting damage to the pontoon can be seen in Figure 15.

- Hot-work operations continue to present a fire risk in the time following work, and the maintenance of a fire watch following hot-work operations is critical when the work area has limited space and objects obstructing a clear view of individual work sites. PIL’s safety management system advised that particular attention should be paid to the need to maintain a fire watch for at least two hours after the completion of hot work. At the time of the incident the fitters had completed the gas cutting and were still at the work site, but there was no crew member present to provide any fire watch.

Safety precautions and the permit-to-work system

- The vessel operator had a permit-to-work system in place, which covered high-risk activities that required additional safety assessments and additional safety measures. Hot work is considered high risk as it includes the use of welding, burning or soldering equipment and power tools that generate sparks. It was included in the list of activities that the operator considered to be high risk and there was a section in the Safety and Emergency Manual that provided specific instructions for carrying out hot work safely.

- A permit-to-work system consists of an organised and predefined safety procedure to guide participants in preparing and executing work safely. In every permit-to-work activity it is crucial to assess the specific tasks to be carried out in a specific place by specific people. In the knowledge that hot work itself is a high-risk activity, consideration should be given to identifying any further hazards in the work area and the safety controls that would be effective and appropriate to lower the risks to an acceptable level.

-

To complete a permit-to-work, one or more checklists must be completed. The checklists used on board the Kota Bahagia contained a series of steps to ensure that a risk assessment was carried out and that safety control measures were in place before hot work was allowed to commence. PIL’s safety management system included the following procedures:

The Chief Officer or Second Engineer shall conduct safety checks and submit the completed checklist (S-02(1) and S-02(2), as revised) to the Master or Chief Engineer confirming that the work to be carried out satisfies the safety requirement (see figures Appendix 1)

Upon approval, the Master or Chief Engineer signs the application and instruct [sic] the Chief Officer or Second Engineer to ensure and monitor the safety requirements

While in port, local regulations should be strictly followed, including the seeking of permission from the Port Authorities

- Local regulations relating to hot-work safety were contained in the local navigation and safety bylaw (Section 4.5, Hawke’s Bay Regional Council Navigation Safety Bylaw 2018). The master of any vessel on which it was proposed to carry out hot work in Napier Port had to obtain a hot work permit from the harbourmaster no less than two hours before commencing the work. On 17 December 2020 the harbourmaster issued a permit allowing the Kota Bahagia to carry out hot-work operations while alongside in Napier Port subject to the following conditions:

All combustible materials within the surrounding area removed or made safe No flammable liquids, vapours, gases or dusts present

Suitable fire extinguishers/hoses on site and fully operational Operator knows how to use firefighting equipment

Operator knows how and where to raise the alarm

An inspection of the surroundings of the work area carried out at least one hour (sic)

- The fitters who attended the vessel to carry out the hot work had completed their own risk assessment and job safety analysis based on the information they had about the gas-cutting job. They had identified fire as the critical risk of the activity and, in the event of a fire, the requirement to raise the alarm and evacuate the vessel. There was very little interaction between the ship’s crew and shore-based workers due to wariness surrounding the COVID-19 pandemic. While the fitters were given a short briefing by the cargo superintendent, they were not given any safety instructions by the vessel’s crew and were not supervised by any crew members. The fitters used a water fire extinguisher to wet the deck prior to cutting and to cool the steel after cutting. Plywood was used as a spark shield, but due to the limited space between the nacelle and the cargo hold bulkhead35, the aftermost36 cargo stoppers were removed without such a control measure.

- PIL’s hot-work procedures and permit-to-work system provided all the necessary prompts to enable the responsible officers to prepare the work site with a low risk of fire and the means to extinguish any fire quickly should it ignite. However, the precautions were not all carried out – they were simply ticked off on the checklist (an uncompleted checklist is set out in Appendix 1). Evidence collected during the investigation showed that fire hoses had not been laid out, the fire main had not been charged, combustible material in the area had not been removed or covered and the shore-based workers had not been supervised by a crew member.

- The crew had all been engaged in stowing the pontoons from number 4 cargo hold and the opportunity was lost to prevent the outbreak of fire in number 2 cargo hold or immediately limit its spread. Although commercial pressures were mentioned by crew members during interviews, the Commission reviewed photographs taken when the nacelles were loaded on board the Kota Bahagia in China. When the cargo stoppers were welded into position around the nacelles, the welder was working alone, with no fire watch person visible, no fire hoses or fire extinguishers visible, and combustible materials visible near the hot-work area. This evidence suggested that the non-compliance in Napier was not an isolated occurrence. The implementation of the prescribed precautions for hot work was not reinforced by the operator’s safety management system, and it is likely that the permit-to-work system had become a paperwork-only exercise.

- A proper risk assessment conducted in the work area prior to the commencement of the hot work would likely have led to the identification of the site-specific hazards and a consideration of effective controls – namely, the difficulties that would be faced in controlling the dispersal of molten material ejected while cutting cargo stoppers placed in almost inaccessible locations.

- At the time of the incident the ship’s crew did not fully implement the requirements set out in PIL’s safety management system and as required by the harbourmaster’s hot-work permit, to ensure the safe execution of hot work by shore-based contractors. The Commission has issued a recommendation to the Director of PIL to address this safety issue.

Co-ordinated incident response

Safety issue: The suppression of the fire was delayed because the various parties involved did not have a shared and consistent understanding of each other’s roles and objectives.

- Numerous parties were involved in the operational working of the Kota Bahagia, and when emergency situations occurred and emergency response procedures were activated, more parties became involved.

- Under New Zealand’s Health and Safety at Work Act 2015, an employer must ensure, so far as is reasonably practicable, the health and safety of its workers while at work. The nature of a port environment means that multiple organisations, of which each has its own safety management system, have to work alongside the framework of the port’s health and safety management system. When an emergency situation arises on board a foreign-flagged vessel, the vessel’s own safety management system and its emergency procedures also need to be taken into account.

- Fire and Emergency NZ responded to the request for assistance from the master and the port. Responding to maritime incidents is an additional function (Section 12 of the Fire and Emergency New Zealand Act 2017) for Fire and Emergency NZ that it performs only to the extent that it has the capability and capacity to do so without compromising its ability to perform its primary functions. Its primary functions (Section 11 of the Fire and Emergency New Zealand Act 2017) include:

- providing fire prevention, response and suppression services

- stabilising and rendering safe incidents that involved hazardous substances

- rescuing persons who were trapped as a result of transport accidents or other incidents.

- In New Zealand, emergencies that require a multi-agency response are supported by the CIMS. Under the CIMS, organisations work together for a common goal under the guidance of a unified command team. An appropriate lead agency is appointed and is responsible for appointing the officer in charge. However, the officer in charge must take into account the objectives of other organisations involved in the co-ordinated incident response.

- Fire incidents are considered to be events that should be managed using the CIMS (CIMS section 1.1.2), so it is reasonable that in this case Fire and Emergency NZ assumed the role of lead agency. In the response to the Kota Bahagia fire, the first senior fire officer on site took the role of incident controller, with the master and crew of the vessel taking on the role of a supporting agency. The CIMS advises that “while the lead agency controller may task and coordinate support agencies’ resources and actions, they must recognise and accommodate the support agency’s statutory responsibilities and/or specific objectives (CIMS section 2.3.2)”.

- For the Kota Bahagia’s emergency response, Fire and Emergency NZ was the lead agency. COVID-19 isolation and quarantine requirements were reassessed, thereby allowing the master and the chief engineer to represent the vessel in the unified command team. Assistance was provided by numerous Napier Port personnel, including two maritime pilots and the safety and emergency management advisor. The harbourmaster and the deputy harbourmaster were not available at the time, so the maritime expertise was provided by the master and the Napier Port pilots.

- The 1978 International Convention on Standards of Training, Certification and Watchkeeping for Seafarers requires masters and seafarers who are designated to control fire-fighting operations to successfully complete advanced fire-fighting training. This training has a particular emphasis on the organisation, tactics and command aspects of fighting fires on board ships. Ship-specific familiarisation training is also required prior to a crew member assuming onboard duties.

- While local shore-based organisations use the CIMS and conduct training and drills using its framework, the masters of visiting ships are not likely to be familiar with its concepts. Similarly, with the objectives of preserving life and restricting the spread of a fire, it may seem counter-intuitive for a senior fire officer to allow a ship’s crew to remain on board to fight it. The master of the Kota Bahagia had the same objectives: preserving life and restricting the fire. Additionally, the master had the knowledge of the ship, its systems and the emergency procedures prescribed by the operator.

- When the first fire service personnel arrived at the port, they observed the cargo superintendent and some crew members directing a hose into the cargo hold, and immediately determined that this was unsafe and an ineffective firefighting response. The ship’s crew were in the very early stages of assessing the location and extent of the fire when the senior Fire and Emergency NZ officer ordered the crew to go ashore.

- The crew were trained and regularly drilled to fight fires on board the ship in accordance with the ship safety management system’s documented emergency procedures. One of the ship’s response parties had started to cool the area around the cargo hatch, but the master had called for them to retreat as the heat and smoke intensified. The master had already assessed that the best approach was to clear the crane wire from the hatch, close the lids and attempt to suppress the fire with CO2. However, despite the loss of response time, on this occasion the master felt it was safer to comply with the evacuation order when explosions were heard from inside the cargo hold.

- Fire and Emergency NZ responders did not initially give due regard to the master’s command status and knowledge of the ship and its systems. Valuable time was lost as the master attempted to convey their intended tactics to the officer in charge of the unified command team. The master stated that it took 20 minutes to obtain agreement on the preferred tactics. As the crew waited ashore, the fire intensified and raised the risks involved with operating the crane and closing the cargo hatch lids. A Napier Port pilot who assisted the unified command team had assessed the viability of other firefighting tactics, but as soon as they heard that there was a fixed CO2 system available they confirmed that every effort should be made to seal the hatch and inject the CO2.

- Once the unified command team had agreed on the firefighting tactics, the crew were allowed to return on board accompanied by fire service personnel. The fire was then suppressed using the vessel’s own fire-suppression capability. It is very likely that the fire would have been suppressed earlier if the crew had been able to continue with the master’s original plan. This incident illustrates the importance of an appropriate initial engagement and exchange of information between masters and shore-based emergency responders. Fire and Emergency NZ personnel could have been thoroughly briefed about the location of the fire and the ship’s firefighting systems and any constraints, and thereby gained a better understanding of the tactics that could be used to extinguish the fire. As a result Fire and Emergency NZ’s and the vessel’s resources could have been merged, and strengthened the ship’s firefighting response and oversight.

- A previous maritime fire that occurred on board the Kokopo Chief in Tauranga (MO-2017-205: Cargo hold fire on multipurpose carrier Kokopo Chief, recommendations 023/18 and 024/18) led to recommendations from the Commission to Fire and Emergency NZ (see 5.11). Training and procedures for ship fires were in need of updating, and a greater understanding between the local emergency services and visiting foreign vessels would likely have led to a more effective response. Since the Kota Bahagia fire, guidance and procedures for ship fires have been updated. However, a revised training regime has yet to be compiled and implemented. Until the revised guidance and procedures are included in Fire and Emergency NZ’s national training programme, there remains a risk of its personnel misunderstanding shipboard emergency procedures and command and control roles when assisting with future maritime incidents. The Commission urges Fire and Emergency NZ to urgently update its training regime to include the latest ship fire procedures and guidance.

Findings Ngā kitenge

- Molten material, ejected during gas-cutting activities, very likely ignited dry sawdust nearby, which created a smouldering fire that ignited the polyvinyl-chloride tarpaulins and other combustible components of the fibre-glass project cargo.

- Hot-work precautions, such as crew supervision and the readiness of firefighting equipment, were not fully implemented.

- The tight stowage of the project cargo made it difficult for the fitters to control the ejection of hot slag beads and sparks and hampered the view and access of the person assisting with the gas-cutting operations.

- Fire and Emergency New Zealand responders did not initially give due regard to the master’s command status and knowledge of the ship and its systems.

- The vessel’s carbon dioxide fire-suppression system could not be activated until the cargo hold was closed and sealed. However, the hatch cover could not be closed until the crane wire and container spreader were hoisted out of the hold.

Safety issues and remedial action Ngā take haumanu me ngā mahi whakatika

General

- Safety issues are an output from the Commission’s analysis. They typically describe a system problem that has the potential to adversely affect future operations on a wide scale.

- Safety issues may be addressed by safety actions taken by a participant, otherwise the Commission may issue a recommendation to address the issue.

At the time of the incident the ship’s crew did not implement the requirements set out in PIL’s safety management system and the harbourmaster’s hot-work permit, or ensure the safe execution and supervision of hot work carried out by shore-based contractors on board the vessel.

- At the time of the incident PIL’s safety management system did not ensure a safe execution of hot work by shore-based contractors.

- Hot work is an acknowledged high-risk activity in the maritime industry. Fire is particularly hazardous to vessels due to their usual state of isolation and limited means of escape. When a vessel is at sea, the crew are relied upon to suppress fires and make attempts to extinguish them. The last resort is to abandon ship. Preventing a fire in the first place is therefore of the utmost importance.

-

The operator has taken the following safety action to address this issue and issued a fleet circular to make its staff aware of the occurrence. The circular stated the following actions that crews should take to prevent a recurrence:

Gaps/holes in the ‘tween decks to be covered by fire-resistant tape in addition to other measures such as using fire blankets to protect areas below the hot work site

Strict fire patrols to be maintained, so that an outbreak of fire may be promptly detected

To improve coordination and communication between vessel management and third-party contractors regarding expectations of fire watchers and firefighting equipment before starting work

This deficiency will be promulgated to the fleet vessels and all ship’s crewmembers to be discussed the circumstances of the incident, reviewed relevant existing fleet circulars, reviewed the risk assessment and went through procedures and processes relating to this work and the role of the fire watch [sic]

Emphasize [sic] [to] senior officers during a pre-joining briefing to avoid recurrence and as a lesson learned

- Additionally, PIL has taken action to improve shipboard procedures for hot work and to ensure better co-ordination with shore workers, using tool-box meetings to identify risks, discuss preventive measures and agree on actions to take in case of a fire.

- The Commission welcomes the safety action to date. However, it believes more actions need to be taken to ensure the safety of future operations. Therefore, the Commission has made a recommendation in Section 6 to address this issue.

The suppression of the fire was delayed because the various parties involved did not have a shared and consistent understanding of each other’s roles and objectives.

- Numerous parties were involved in the operational working of the Kota Bahagia, and when an emergency situation occurred and emergency response procedures were activated, more parties became involved.

- Fire and Emergency NZ took the role of lead agency for a co-ordinated emergency response. The master followed orders to evacuate all crew to the quayside with the knowledge that it would delay the use of the vessel’s fire-suppression systems.

- It is likely that the fire would have been suppressed sooner if the co-ordinating parties had had a better understanding of their respective roles and objectives.

-

The previous maritime fire that occurred on board the Kokopo Chief in Tauranga (see 3.29) was investigated by the Commission and led to the following recommendations to Fire and Emergency NZ

On 19 September 2018 the Commission recommended to the Chief Executive Officer of FENZ that he review its procedures for firefighting on board ships to ensure that they accurately reflect the mandated responsibilities of the ship’s master, the harbourmaster and any other person or organisation that could be involved. (023/18)

On 19 September 2018 the Commission recommended to the Chief Executive Officer of FENZ that he review the FENZ training standards to ensure that they contain sufficient training in the unique aspects of fighting fires on board ships. (024/18)

- Fire and Emergency NZ accepted these recommendations, and the responses indicated that reviews of the ship fire procedure and the training modules for maritime incidents would be completed in 2019. In December 2020, when the Kota Bahagia fire occurred, these reviews had not been completed. The response to the fire on board the Kota Bahagia raised similar safety issues to those identified in the Kokopo Chief investigation. This indicated the importance of addressing the safety issues and recommendations previously raised by the Commission.

- Guidance and procedures for ship fires have now been updated, and the documents clarify the status and authority of the master. The new ship fire reference guide was published in September 2021 and the new ship fire procedure was published in April 2022. However, a revised training regime has yet to be compiled and implemented. The Commission urges Fire and Emergency NZ to urgently update its training regime to include the latest ship fire procedures and guidance.

- Since the incident, Fire and Emergency NZ has been working closely with Napier Port Limited (see 5.14) and the Port and Harbour Marine Safety Code technical group to establish more formal and collaborative procedures. The Commission welcomes this action and encourages Fire and Emergency NZ to continue to collaborate with other port companies in developing their own joint procedures as appropriate.

Other safety action

- Participants may take safety actions to address issues that would not normally result in the Commission issuing a recommendation.

- The following safety actions have been taken by Napier Port Limited:

- All fire hydrants and access to firefighting capability on port were formally identified. All hydrants, water mains risers and pump facilities on port have been painted with distinctive markings

- Napier Port carried out an operational review with Fire and Emergency New Zealand. Tactical firefighting planning and contingency plans have been more formally identified and established. Site orientation and port emergency simulation exercises between Napier Port and Fire and Emergency New Zealand are ongoing

- Napier Port’s working relationship with Fire and Emergency New Zealand has been more formally strengthened as a result of working through the Kota Bahagia fire incident, recovery and operational review phases.

- The Commission did not identify any safety issues with respect to Napier Port’s response to the Kota Bahagia fire, but welcomes these additional proactive safety actions.

Recommendations Ngā tūtohutanga

General

- The Commission issues recommendations to address safety issues found in its investigations. Recommendations may be addressed to organisations or people, and can relate to safety issues found within an organisation or within the wider transport system that have the potential to contribute to future transport accidents and incidents.

- In the interests of transport safety, it is important that recommendations are implemented without delay to help prevent similar accidents or incidents occurring in the future.

New recommendations

- On 8 July 2022 the Commission recommended that Pacific International Lines take further steps to ensure that the safety precautions prescribed in its Safety and Emergency Manual are implemented effectively on board its vessels. (011/22)

- On 12 July 2022, Pacific International Lines replied by restating their actions taken in response to the accident that have already been included in section 5 of this report. The Commission believes that further action is still required to meet the intent of this recommendation.

Current recommendations

- In 2018 the Commission issued recommendations to Fire and Emergency NZ (see 5.10) to address its training and procedures and to establish a better understanding of the unique aspects of fighting fires on ships and the responsibilities and obligations of masters and crews.

- These recommendations have yet to be implemented and the Commission reiterates the need for Fire and Emergency NZ to do so with urgency.

Key lessons Ngā tūtohutanga

- A risk assessment for hot work should give particular consideration to the contents of and any constraints in the area where the hot work is to be carried out. The risk assessment should be applied systematically and then monitored to ensure compliance.

- A shipboard fire response is based on the vessel’s design, fire protection systems and crew numbers. Shore-based firefighting assistance and incident management systems should enhance and support the response made by the ship’s crew, not erode it.

Data summary Whakarāpopoto raraunga

Details

Conduct of the inquiry He tikanga rapunga

- On 18 December 2020 Maritime New Zealand notified the Commission of the occurrence. The Commission subsequently opened an inquiry under section 13(1) of the Transport Accident Investigation Commission Act 1990 and appointed an investigator in charge.

- On 18 December 2020 the Commission issued a protection order on number 2 cargo hold.

- On 19 December 2020, after taking appropriate measures to mitigate the risk of contracting or transmitting COVID-19, two investigators attended the vessel alongside in Napier. They commenced interviews of crew, port workers and other participants and witnesses. Evidence collected included port CCTV (closed-circuit television), drone footage from Fire and Emergency NZ and witness videos of the fire.

- After the fire was declared extinct on 24 December 2020, safety planning commenced to ensure that all investigative parties could access number 2 cargo hold safely. The site contained multiple hazards following the fire.

- On 7 January 2021 the Commission engaged a specialist fire investigator to determine the origin and cause of the fire.

- On 10 January 2021 two investigators and the specialist fire investigator conducted a scene examination of number 2 cargo hold.

- On 15 January 2021 the Commission lifted the protection order on number 2 cargo hold.

- On 10 and 11 February 2021, two investigators carried out follow-up interviews and document collection in Napier.

- On 23 February 2022 the Commission approved a draft report for circulation to 12 interested persons for their comment. The Commission received nine responses, which included three submissions.

- The Commission considered these submissions in detail. Any changes as a result of the submissions are included in the final report.

- On 8 July 2022, the Commission approved the final report for publication.

Glossary Kuputaka

- Aft

- At, near or towards the stern of a vessel

- Boundary cooling

- The use of water to cool the outside of a burning structure and restrict the spread of a fire.

- Bulkhead

- Nautical term for a wall

- Cargo stoppers

- Cargo-lashing devices consisting of steel plates welded to the deck to prevent cargo sliding and tipping. Additional pieces of steel can be welded to these plates to prevent the vertical movement of cargo.

- Cargo superintendent

- A shore-based worker engaged by a cargo owner to assist with managing cargo unloading. They inspect the cargo prior to discharge and after landing, and liaise with all relevant onshore and offshore departments.

- Clean burn

- An effect created when a fire is of sufficient intensity to remove the coating created by the smoke plume, exposing the substrate underneath, in this case the steel bulkhead of the hold.

- Container spreader

- A rigid framed, four-point lifting device that connects the crane wire to the corner-castings of shipping containers. Used for loading and discharging shipping containers. The man-cage can be seen on the right.

- Timber dunnage

- Packaging material, such as timber blocks and boards, air pillows and foam, used to prevent damage to cargo and to provide friction between cargo and a deck.

- Fitters

- Workers who install and remove machinery, pipes and other equipment.

- Forward

- Towards the front, or bow, of a vessel

- Hot work

- Work requiring the use of welding, burning or soldering equipment, blowtorches and tools that generate sparks.

- Emergency muster stations

- Designated emergency areas for all crew during emergencies. The master and crew confirm the whereabouts of all personnel and initiate a plan to address the emergency using specialist equipment.

- Nacelles

- A nacelle is the part of a wind turbine that houses the generating components and control electronics.

- Port pontoon

- Alloy buoyancy chamber around the periphery of the hull

- Project cargoes

- A term used broadly to describe large, heavy, high-value pieces of equipment, often associated with large capital projects such as those involving plant and wind-farm machinery.

- Stevedore

- Shore-based worker who loads and unloads cargo when vessels are in port

- Tween deck

- A space between two continuous decks of a vessel. In this case the ‘tween deck was made by inserting removable pontoons to divide the cargo hold, creating an extra deck between the bottom of the cargo hold and the hatch top.

Appendix 1. PIL hot work checklists

Related Recommendations

On 8 July 2022 the Commission recommended that Pacific International Lines take further steps to ensure that the safety precautions prescribed in its Safety and Emergency Manual are implemented effectively on board its vessels.