Since the accident Princess Cruise Lines Limited (the owner/operator) has taken the following safety actions:

On board the Emerald Princess – all nitrogen cylinders on board were immediately closed as a precaution. A visual inspection was then undertaken of all cylinders and, once it was clear that corrosion may have been the cause of the failure, all cylinders on board were depressurised and replaced. This process was completed by 9 March 2017; and across the entire fleet, including:

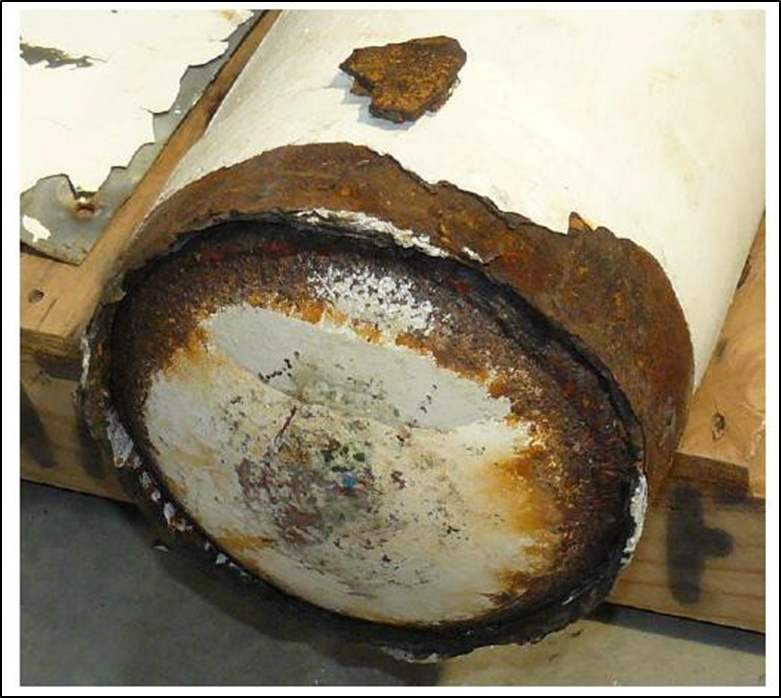

a fleet-wide visual inspection of all nitrogen cylinders for corrosion. No serious defect was observed from this inspection, although the Group’s safety team noted that, given the circumstances of the incident, a normal visual inspection was insufficient to identify material corrosion in all circumstances. This observation has been taken into account in the long term policy revisions (as to which, see below);

a fleet-wide inventory of all nitrogen cylinders, including locating and confirming the manufacture dates and certificates. A simultaneous process was put in place to verify the inventory data, which was then entered into AMOS, the planned maintenance system used by the fleet, to ensure there were no gaps or discrepancies; and

a large number of new cylinders were sourced in anticipation of the need to carry out replacement across the fleet due to the 10-year maintenance/age requirement. In total, over 800 cylinders have now been replaced.

Further, a number of long-term policy and procedure revisions have taken place, reflecting an acknowledgment that the incident highlighted that there were areas in which existing procedures could be enhanced to ensure crew safety. In particular, there has been a review of the planned maintenance systems, with the involvement of all vessels, and the AMOS work orders in relation to nitrogen systems on launching appliances have been updated. Their guidance and/or job descriptions now contain clear instructions regarding the dates of manufacture, inspection frequencies and requirements, and other relevant information. In additional, AMOS has been changed to permit tracking (and does track) each cylinder individually.

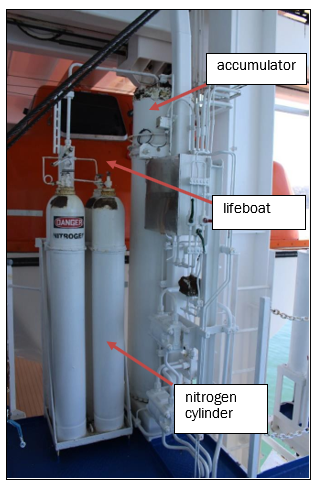

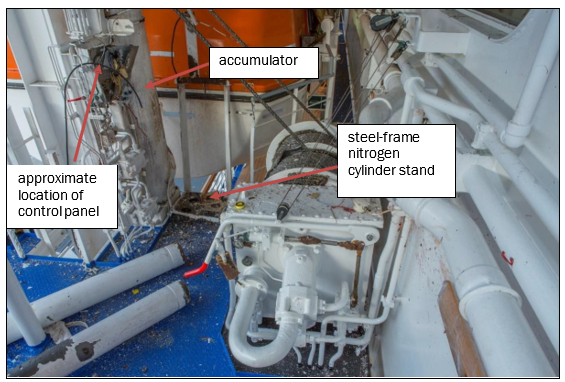

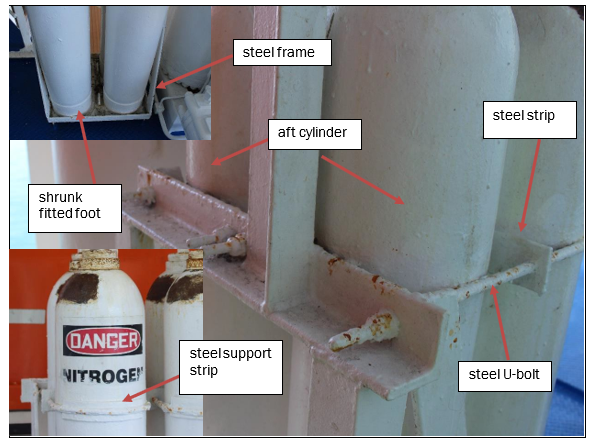

Standardised guidance has been issued for nitrogen cylinder installations at LSA launching stations. Because the storage and installation of the nitrogen cylinders in the LSA launching arrangements was found to be a potential contributing factor to the onset of corrosion, the guidance eliminates steel-to-steel contact between all surfaces to mitigate this. Adequate securing and protection, by means of Teflon pads, rubber strips or similar material is required to be used. This set-up also allows for better visual inspections of the individual cylinders by both the crew members and approved service providers.

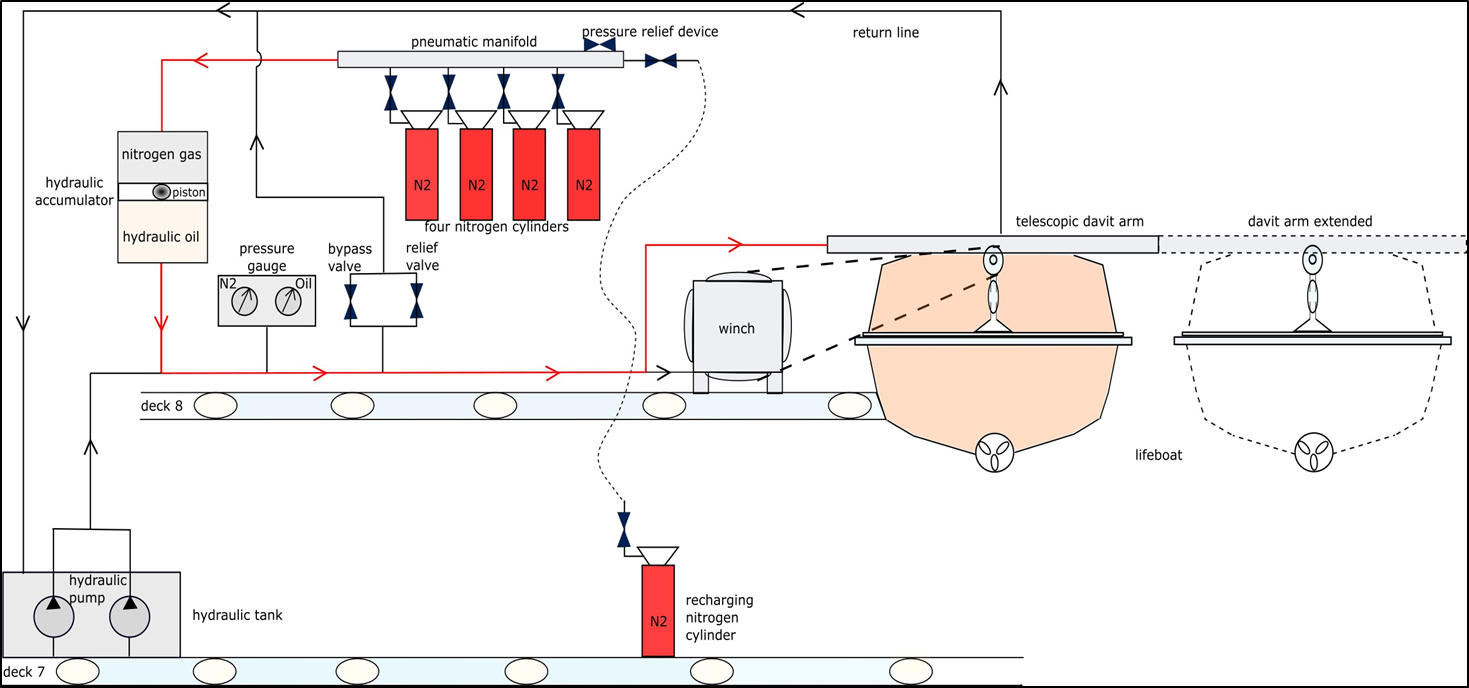

[X] “Nitrogen Bottles Top Up Procedure for Hydraulic Piston Accumulators”. Following the incident, the Group worked with [x] to sure there was one standard instruction available in this regard. This document is attached to the relevant Fleet Maintenance Manual and a ship’s Staff Chief Engineer or someone at his or her direction ensures that topping-up is performed, by a qualified Fitter, in accordance with the instructions that it contains each time topping-up is required.

Safety Bulletin SB 005-17, dated 1 August 2017, which has been issued with the following directions (the heightened awareness in the Technical and Safety Departments in relation to these systems, arising from the incident, was a significant factor in the production of the Bulletin):

A risk assessment of the LSA nitrogen refilling job should be available on board. All personnel assigned to this job should be familiar with it.

Risk assessments should be conducted for any job involving the transfer of (high pressure) gasses as required by OHS-1407.

Ships should ensure that:

For the LSA nitrogen refilling job they have the proper gas transfer kit available. Note that for all [x] systems this is in AMOS and can be found through Makers Reference: U01409.

The correct gas transfer equipment is available for all similar jobs. All recharging kits should be fitted with pressure reducers, gauges, and bleed valves. Where not available, this should be ordered through the technical department.

Standardised instructions from [x] “NITROGEN BOTTLES TOP UP PROCEDURE FOR HYDRAULIC PISTON ACCUMULATORS 40002-39-099-A” must be followed during the LSA launching appliance recharging process.

Such equipment must be kept in a controlled environment, clearly labelled and only used for its intended purpose.

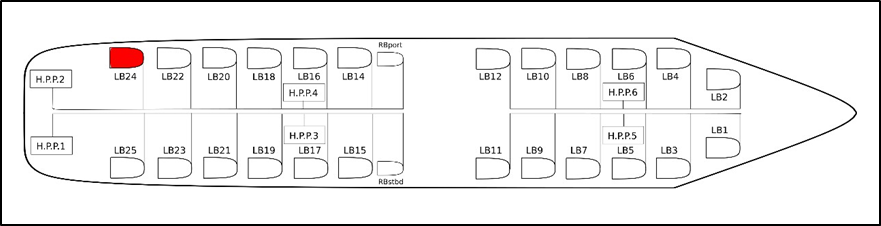

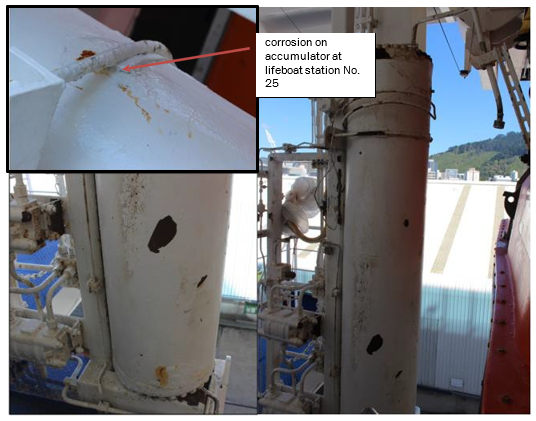

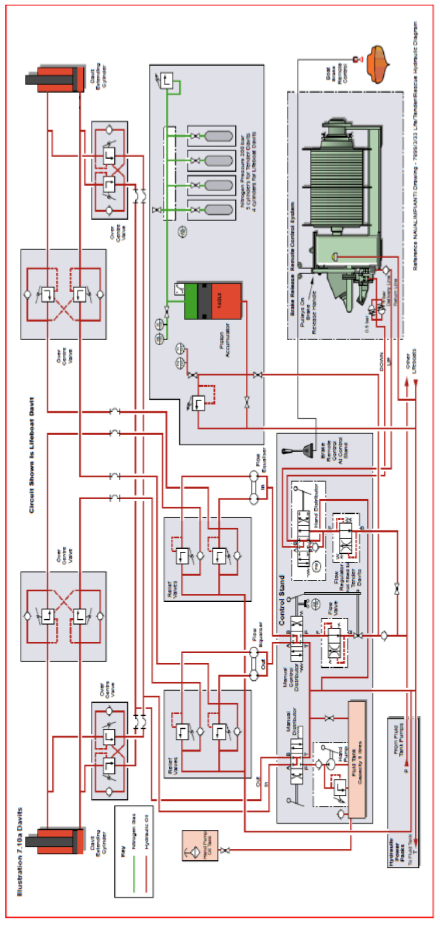

Work order “LSD201 – Monthly Davit inspection and turnout”. This is conducted by a ship’s crew. You will see that one of the goals of the task is to “ascertain the physical condition of the stored-pressure systems for the launching appliances”, in accordance with the requirements set out. This includes checking the separation of the cylinders and accumulators from steel and other metallic components, to reduce contact corrosion and corrosion due to paint removal from abrasion. It also includes an inspection of the external appearance of the cylinders, stands and securing arrangements for signs of corrosion or defect. Any areas of concern are to be reported immediately to the Staff Chief Engineer and followed up with the ship’s Technical Operations Director. The AMOS history is updated following and, in the event of defects, work orders are raised.

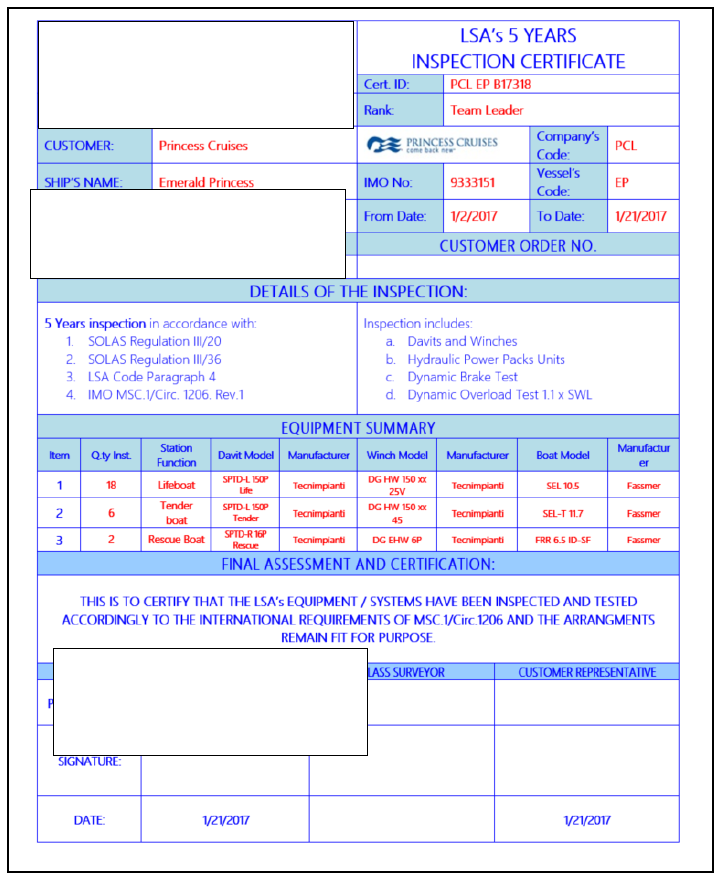

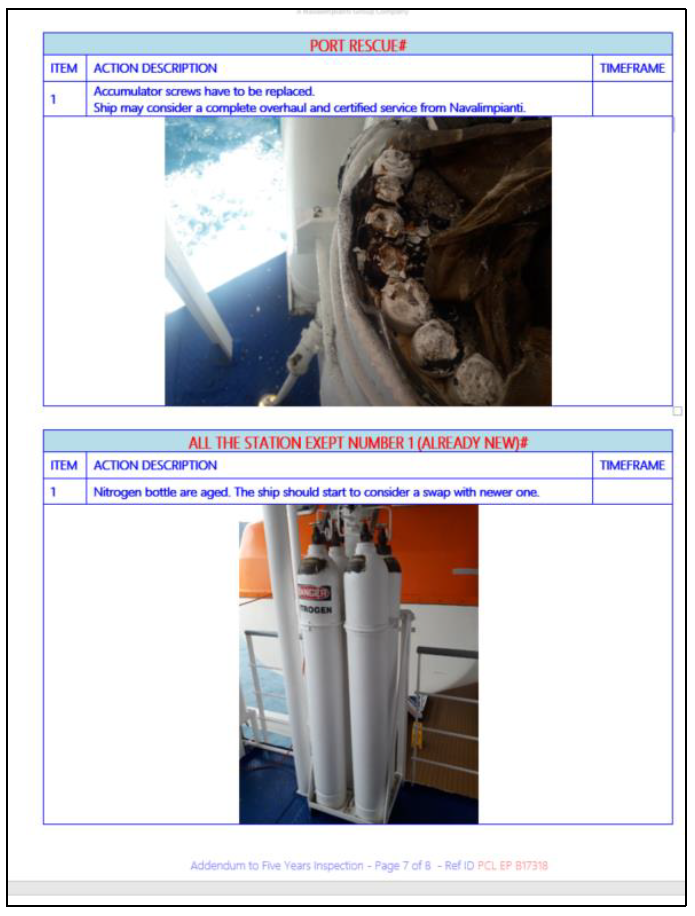

Work order “LSD203 – Annual inspections of the LSA launching appliances by approved service provider”. As you know, this is conducted generally by [x]. The details of this work order have been amended. It now requires full isolation of each system so that there can be a full inspection of each cylinder and its connections. The external surface of each cylinder is cleaned thoroughly and then inspected for any defects. Serial numbers and manufacture dates are verified and checked against on-board records to ensure the cylinders are within their 10 year lifespan. The findings of the inspections are required to be recorded in the service provider’s report. An example [x] inspection/service report from July 2017, containing detailed information about nitrogen cylinders, is also attached. Any findings of significance are recorded in AMOS and the vessel’s Technical Operations Director is notified. Where a specific item of work needs to be performed on the system, it will be noted in AMOS and a work order raised.

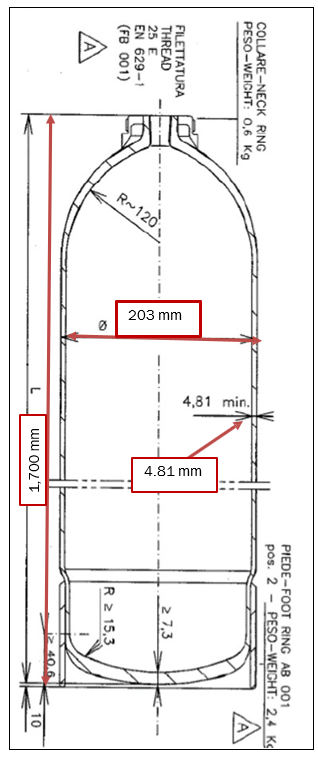

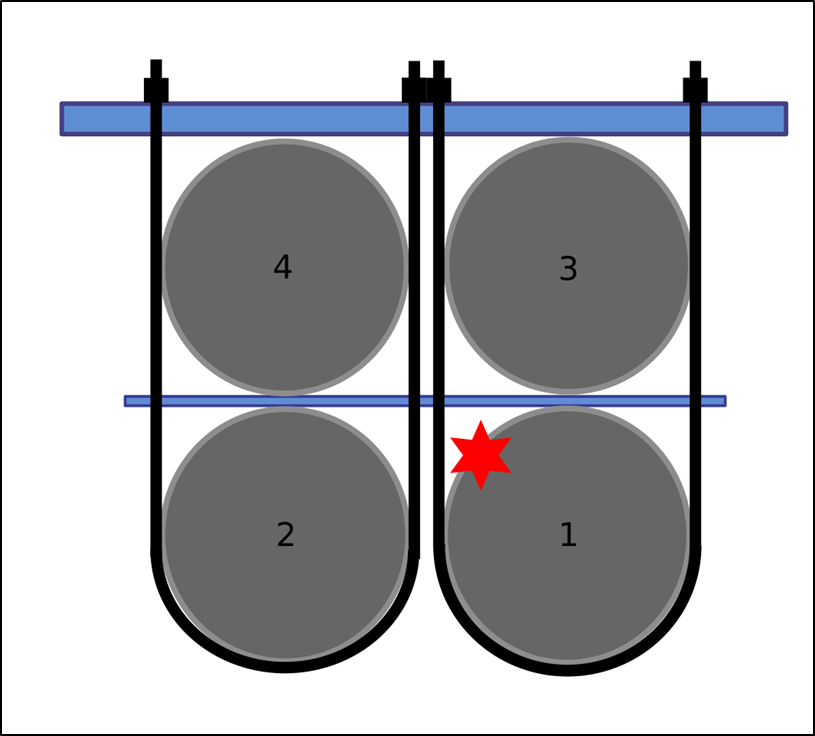

Work order “PAT0039 – 10 year replacement of cylinders”. This requires that Nitrogen cylinders (and bladder-type accumulators in the LSA launching appliance systems) are to be replaced on or before the 10 year anniversary of manufacture17. Relatedly, the system of monitoring or tracking cylinder age and condition in AMOS has been changed. The previous system involved collective monitoring, based on cylinder installation date. As above, cylinders are now individually tracked in AMOS based on their manufacture date. This is reflected in the work order, which provides that when new cylinders are installed, the “MANUFACTURE date (stamped on the collar of the cylinder…) and NOT the installation date must be entered within Amos and on-board records…”

Work order “PAT0040 – 10 year overhaul and test of piston-type accumulators”. This job has been added to ensure these accumulators undergo a full overhaul (including dismantling, replacement of seals and full internal and external inspection) and a system test every 10 years. Where possible, these units are also returned to the vessel with galvanic protection against corrosion.