Parachute particulars

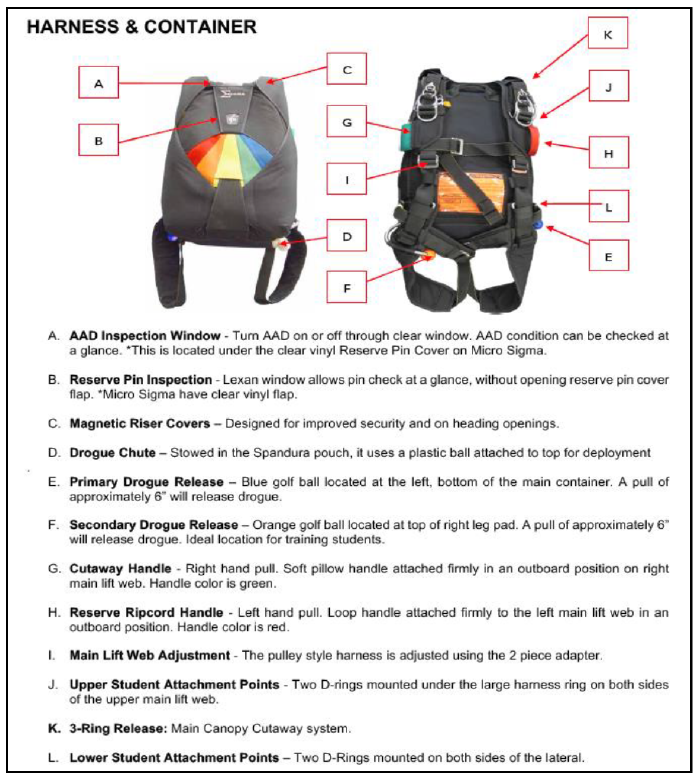

Harness and container:

Micro Sigma, serial number 66126, manufactured in the USA, May 2017, by UPT in accordance with FAA TSO C23b NZONE rig number C46 and CAA ID number 31Z

Main parachute:

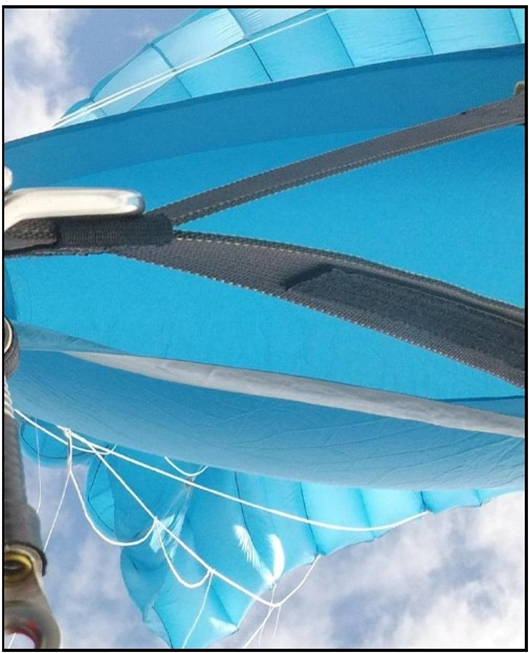

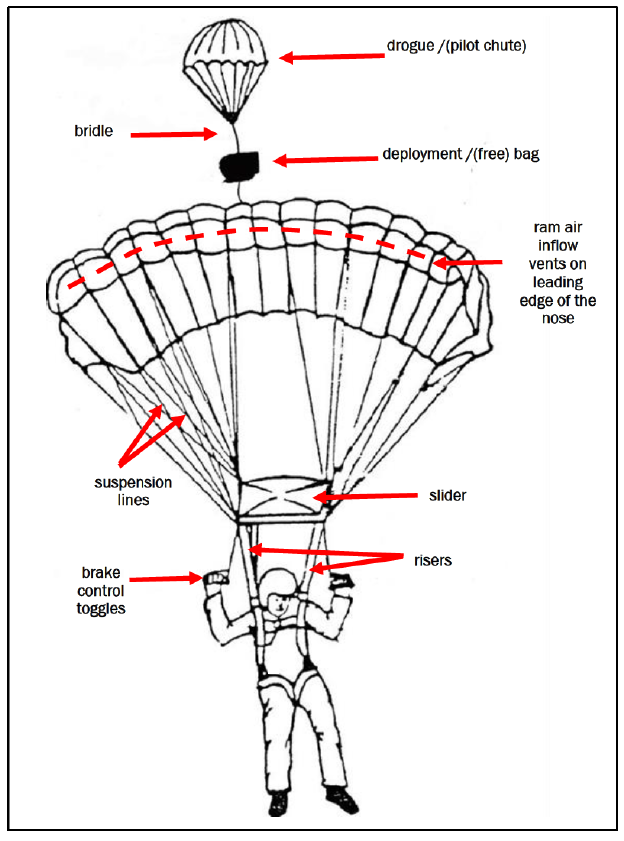

Icarus Tandem, serial number 13096, manufactured in New Zealand, October 2017, by NZ Aerosports Limited

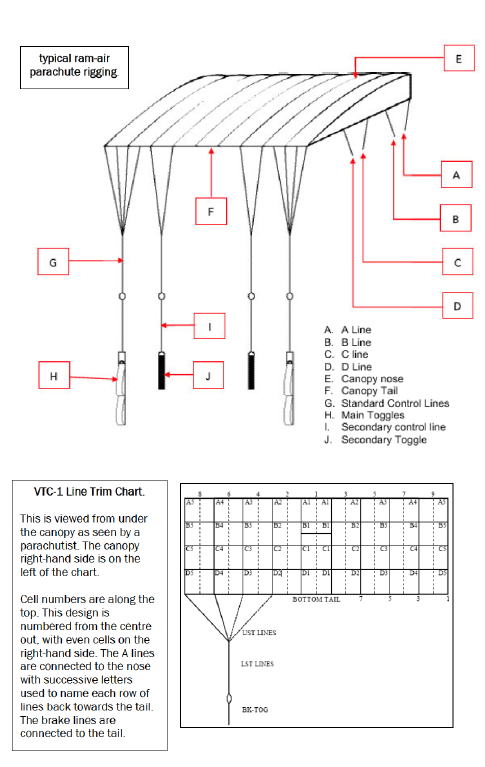

300 sqft (28 m2), mildly elliptical-shaped, nine-cell ram-air wing made with zero-porosity, ripstop nylon. Fitted with HMA 1200, black, suspension lines

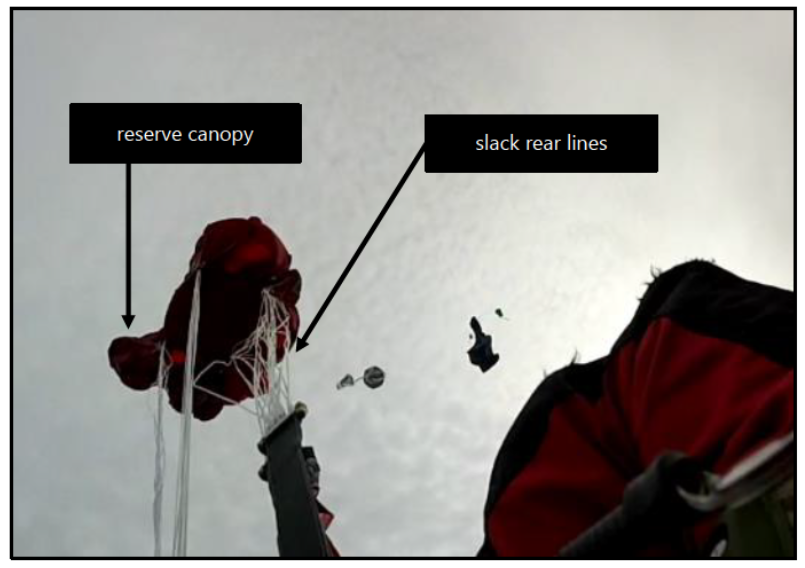

Reserve parachute:

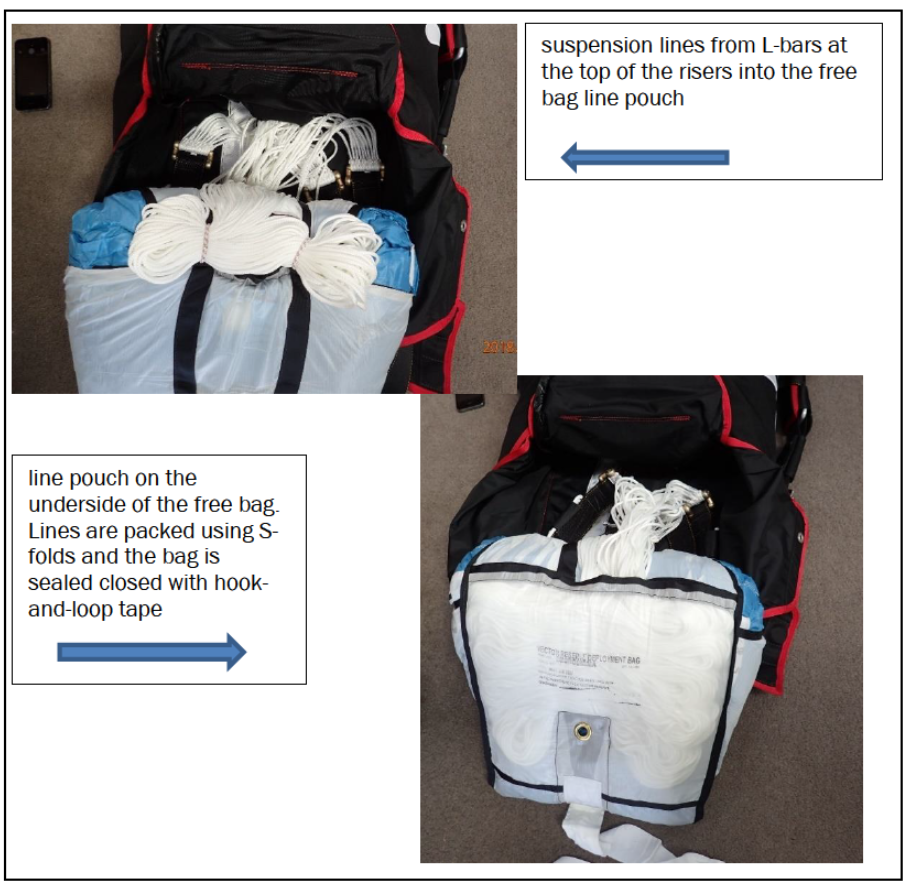

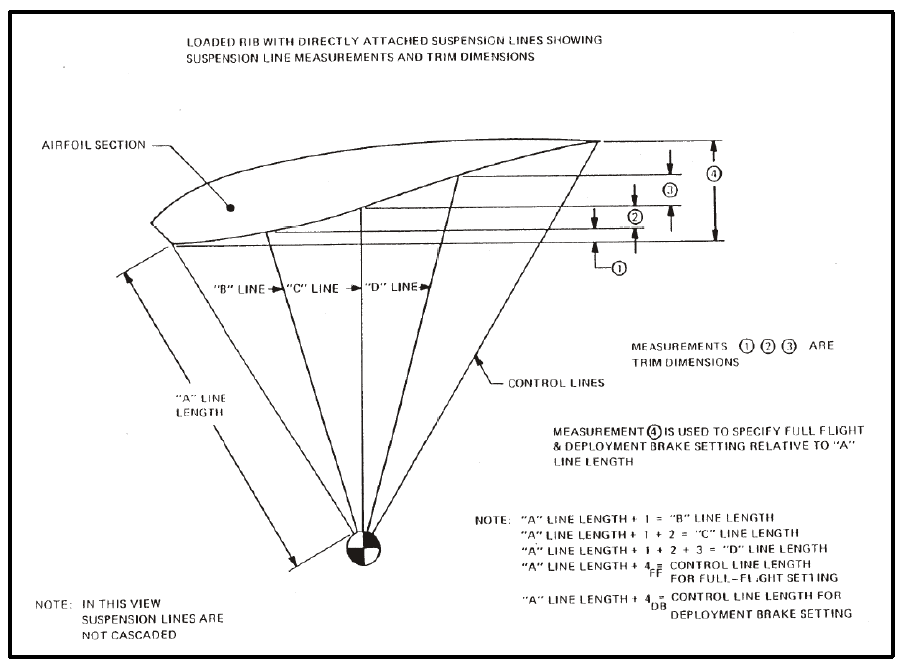

model VTC-1, reserve serial number VR-360 009397, nine- cell ram-air square wing, manufactured in May 2017 in accordance with FAA TSO C23b for UPT by Performance Designs as its model Vector Tandem II (also described at times as a model PD VR360)

surface area of 360 sqft (33 m2) of F111 ripstop nylon with Dacron, continuous suspension lines

Automatic activation device:

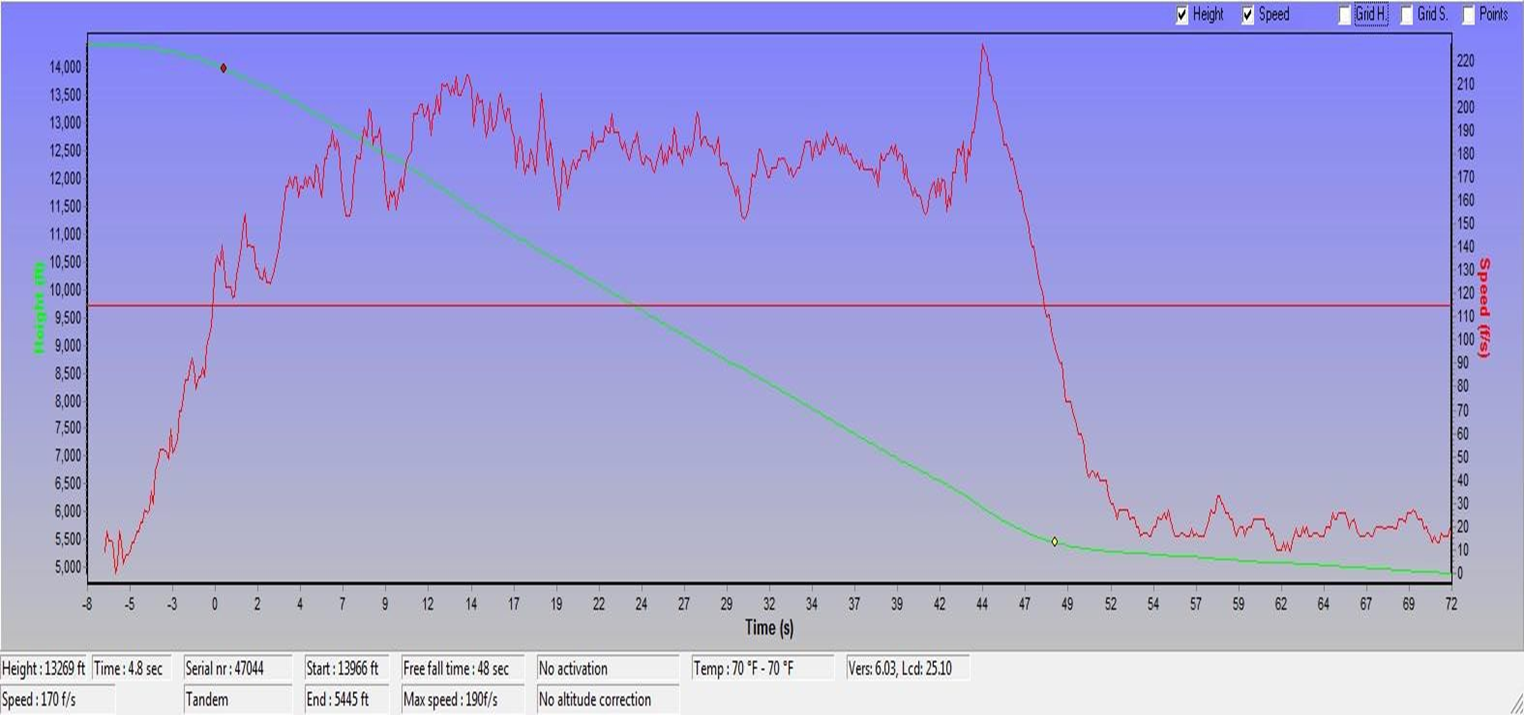

Advanced Aerospace Designs – Vigil II+ serial number 47044. Manufactured in Belgium, December 2015

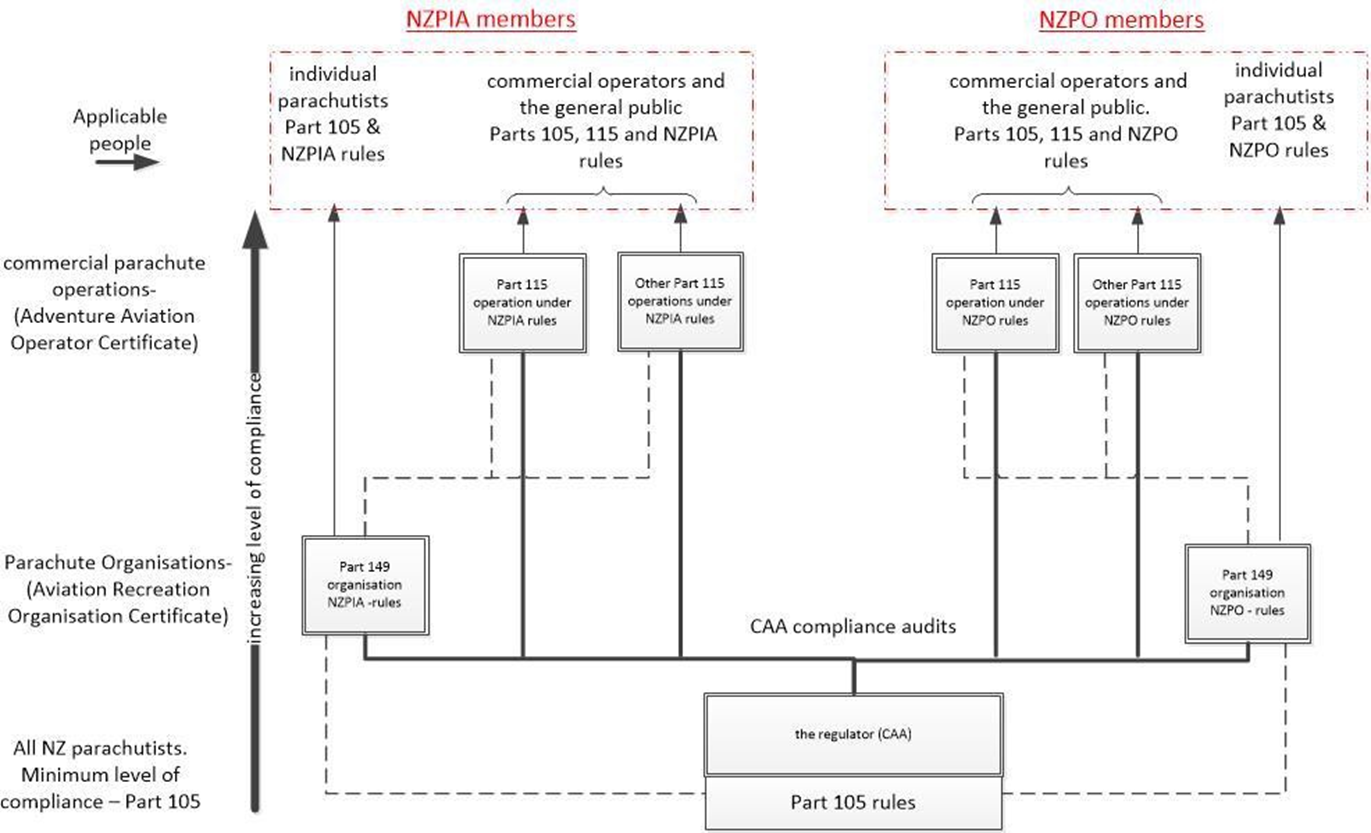

Operator:

Skydive Queenstown Limited, trading as NZONE Skydive and Skydive Southern Alps

Type of flight:

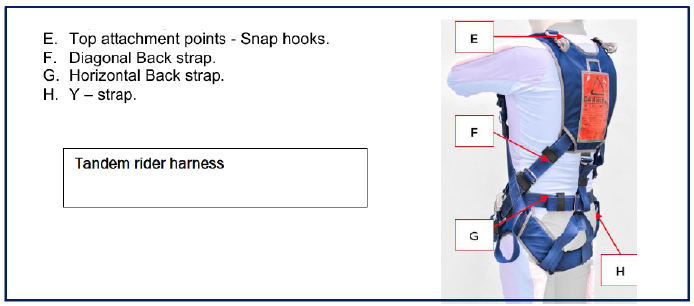

commercial tandem skydive

Persons on board: two

Parachute load factor:

tandem master/rider = 65/72 kg

rig/gear estimate = 30/15 kg

total load estimate: 182 kg

main = 182 kg/300 sqft = 0.607 kg/sqft

reserve = 177 kg/360 sqft = 0.491 kg/sqft

Crew particulars

Tandem master’s licence:

NZPIA, Commercial Parachute Certificate

Tandem master’s age:

25

Tandem master’s experience:

approximately 4,000 total parachute descents including about 2,500 tandem and 900 base jumps

Date and time

10 January 2018, 1330

Location

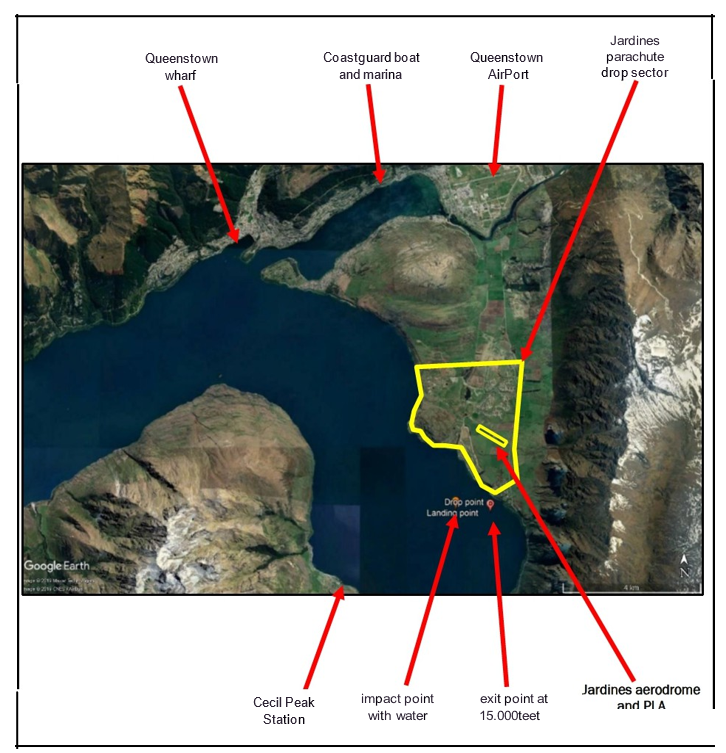

Queenstown

latitude: 45° 6´ S

longitude: 168° 43´ E

Injuries

One fatal, one minor